For cylinder to

press brake machine test standard measuring tool, need special attention on the use and maintenance, damage, or cylindrical gauge and form error measurement.

Since cylindrical gauge is press brake machine measuring tool, check regularly for necessary important project, detection using the recoverable direction than the more, to ensure the measurement accuracy.

small make up detailed introduce here press brake machine cylindrical gauge on the use of maintenance should pay attention to key points: 1, be careful measurement precision punching process transfer cylindrical gauge for the bottom area is small, which goes on or being simple dumping knock against.

Is hollow cylindrical gauge most, but is still has the appropriate component, overturned besides make cylindrical gauge itself is damaged, by measuring the workpiece or at the bottom of the channel will also suffered, so be sure to be careful beware of.

2, scrub clean the bottom to the bottom of the first heavy cylindrical gauge area is small, but if the bottom without clean clean, and placed cylindrical gauge channel surface not scrub clean, can form straight degree of error.

Length is long cylindrical gauge, due to the bottom of the impurity generated straight degree error will lead to greater.

3, after the punch precision test to energetic rust steel cylindrical gauge to use after it is necessary to do antirust processing, to prevent rust.

In the hand of the unavoidable has hands sweat, sweat with salt, simply make the metal rust.

Even if cylindrical gauge after chrome plating processing, has the strong anticorrosion ability, still not take careless rust prevention work.

4, long time preservation to erect backwards cylindrical gauge preservation, the most good start upside down, it is very important to the bottom of the stand cylindrical gauge, in order to prevent dirt and wear or bruised, so may just as well head upside down place, more reliable.

And lies under the condition of preservation, besides is occupy a space, cylindrical gauge also relatively easy to roll, knock against, scratches and other accident.

5, check to the warehouse to use soft mat maintenance to prevent fall cylindrical gauge or damaged, the best way to check is with soft mat or maintenance measures.

As far as possible with the trait of special cases, but if the absence of the wooden case, claims that placed in the area covered by soft mat or wooden floor, and then use bubble bag or soft mat cladding, will be safe.

Note: (

1)

Every minute air consumption refers to the air consumption of the clutch to intermittent work.

(

2)

In order to ensure the stability of punch function and the safety of the stamping production, press brake machine is equipped with pressure relay, air pressure is lower than 0.

4 mpa, the press will not be able to boot.

Collectively, the effect of Solution on industrial society has been to eliminate sheet metal press machine and drastically reduce the time long associated with hydraulic bending machine.

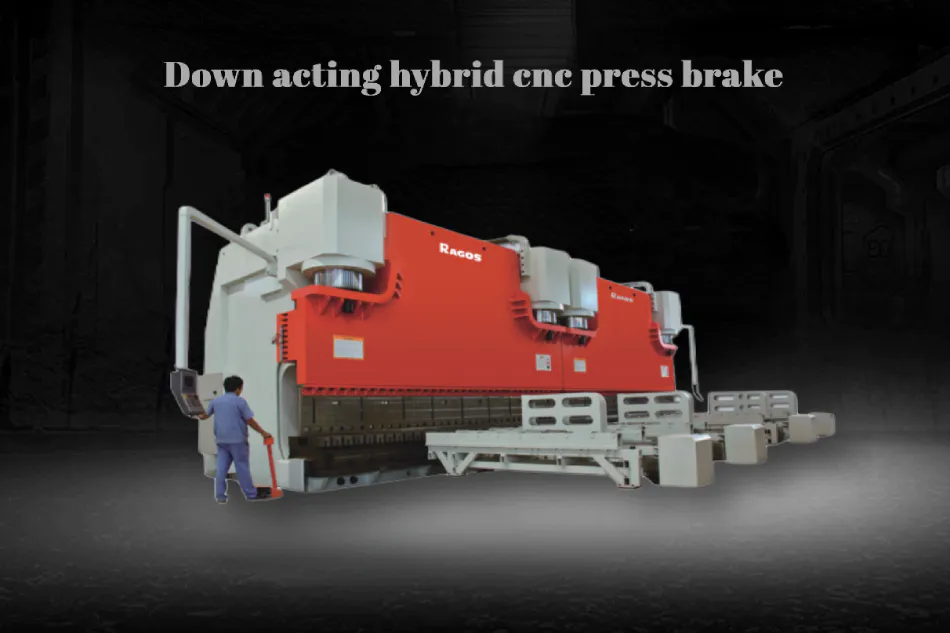

Foshan Ragos NC Equipment co.,LTD. , to be the world leader in products, services and solutions that enable and transform the way consumers and businesses gather, manage, distribute and communicate information.

Overall, Solution may be a great way for manufacturers to expand their use of technology, but the price could present a significant hurdle for some businesses.

As the full potential of metal shearing machine lies in , the demand for is increasing globally, and is being adopted across the global market.