Brand:RAGOS

Payment Type:T/T

Incoterm:FOB,CIF.EXW

Min. Order:1 Set/Sets

Transportation:Ocean

Port:GUANGZHOU-NANSHA,SHENZHEN-SHEKOU

Machine Type:Synchronized

Place of Origin:FOSHAN CHINA

Machinable Material:Stainless Steel, Alloy, Carbon Steel, Aluminum

Additional Features:Machining

Out-of-warranty Service:Video Technical Support, Online Support

Applicable Industry:Machinery Repair Shops, Manufacturing Plant, Other, Building Material Shops, Energy,Amp; Mining

Where To Provide Local Services :Egypt, Canada, Turkey, India, Russia

Showroom Location (in Which Countries Are There Sample Rooms Overseas):Egypt, Canada, Turkey, Russia

Marketing Type:Other

Mechanical Test Report:Provided

Video Factory Inspection:Provided

Core Components:Bearing, Engine, Other, Pressure Vessel

Packaging:Ragos standard export packaging

Certificate:CE

Packaging & Delivery

Selling Units:Set/Sets

Package Type:Ragos standard export packaging

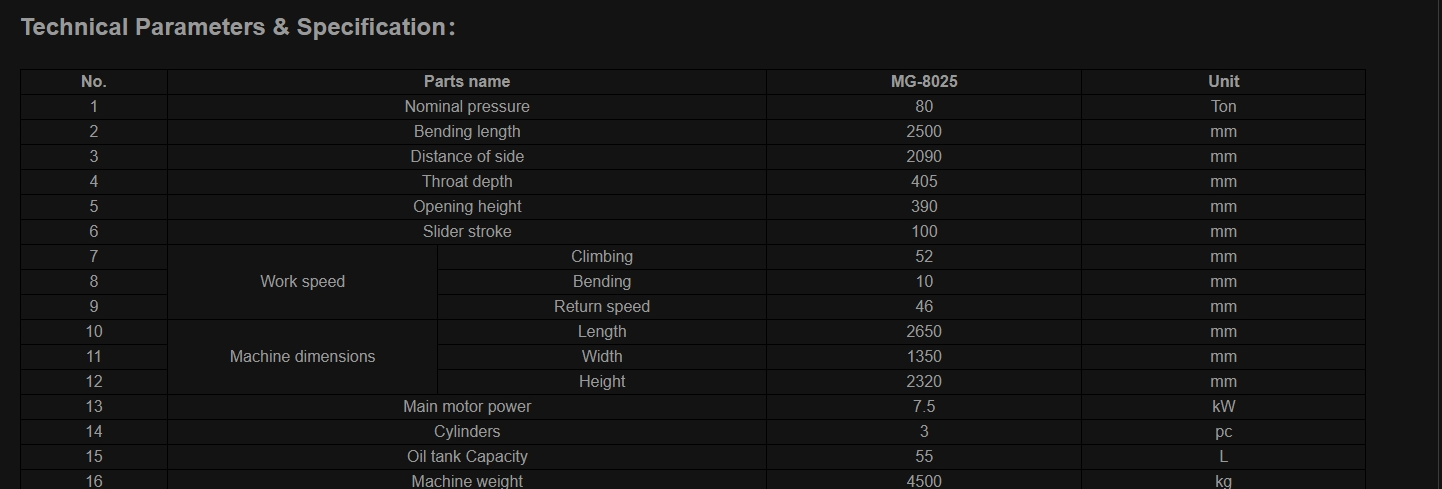

Product keywords:Panel bender,Press brake,cnc bending machine,Dual servo hybird cnc press brake,Down-acting press brake,Up-acting press brake,full electric servo press brake,V-Grooving machine,

Although the manufacturing and accuracy of sheet metal equipment bending machines have been greatly improved than in the past, there is still a big gap between the "Road to Industry 4.0" and "Intelligent Manufacturing and Made in China 2025". "Personalized customization, service-oriented extension, and networked collaboration" also require joint innovation and development in the subdivision of sheet metal equipment manufacturing and the demand side. This innovative development, promotion and application is another increase and liberation of productivity.

The traditional bending of the sheet metal industry needs to solve the following problems: (1) Manufacturing problems: can not achieve multiple varieties, small batches, and fast switching; (2) The problem of low precision of parts: low precision of high-precision workpieces in the sheet metal industry. Unstable quality; (3) The problem of difficult employment for enterprises: the shortage of sheet metal bending operators and the high labor intensity of workers; (4) Comprehensive problems: personnel costs, safety hazards, process layout, management and operation.

111

Copyright © 2025 Foshan Ragos NC Equipment co.,LTD. (panel bender) | All Rights Reserved

We are here to help you! If you close the chatbox, you will automatically receive a response from us via e-mail. Please be sure to leave your contact details so that we can better assist you.