Up-acting press brake

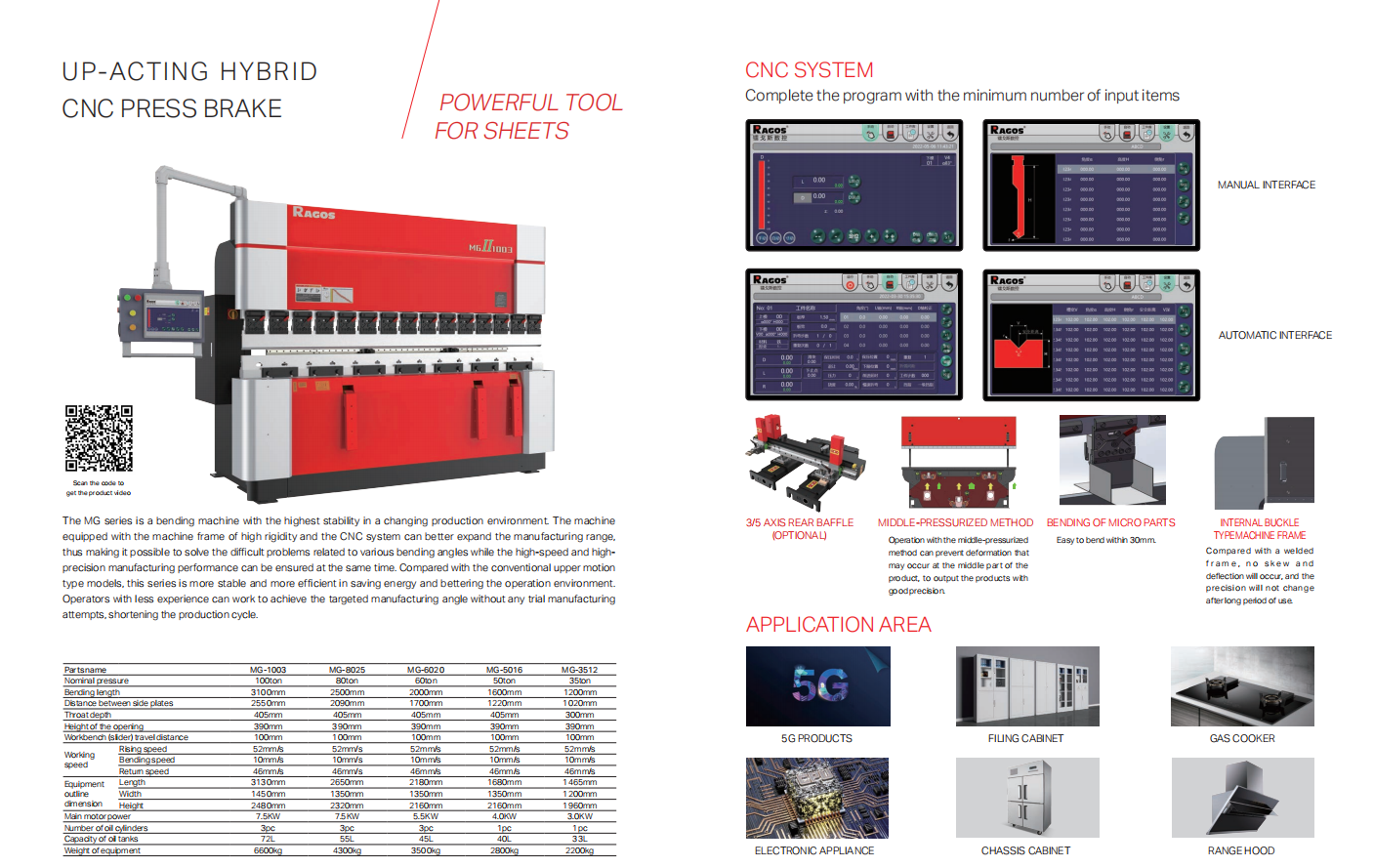

Product name:Up-acting Hybrid CNC Press Brake---It has a good effect on the thin plate series

Product model:

MG-3512 35ton

MG-5016 50ton

MG-6020 60ton

MG-8025 80ton

MG-1003 100ton

operating system:

Standard:RAGOS LT15

Optional: RAGOS TY12/TY15

Switzerland:CYBBELEC Cyb Touch CT8/CT12/CT15

Netherlands: Delem DA53T/DA58T/DA66T/DA69T

Product Details:

File Cabinet Processing

Intermediate Pressurization

Easy to Bend Within 30mm

Thin plate sharp tool

According to the feedback from cylinder suppliers, our company is currently the manufacturer with the most comprehensive dimensions and the largest shipments in China.

Three oil cylinders over two meters

Oil pump life up to 20 years

The down-moving bending machine is a common sheet metal processing equipment, also known as the down-stroke bending machine or the pendulum bending machine. It is mainly composed of fuselage, workbench, upper mold, lower mold, control system and so on.

The working principle of the down-moving bending machine is: put the metal sheet on the workbench, the upper mold presses the metal sheet, and the lower mold moves downward, so that the metal sheet is bent between the upper mold and the lower mold, and finally forms the desired shape. desired shape. The advantages of the down-moving bending machine are simple operation, high bending precision, wide application range and high production efficiency.

Down-moving bending machines are widely used in various sheet metal processing industries, such as machinery manufacturing, aerospace, automobile manufacturing, electronic communications, etc. It can be used to produce various parts, such as chassis, racks, frames, brackets, etc.

The down-moving bending machine has the following advantages and characteristics:

1. Simple operation: The operation of the down-moving bending machine is relatively simple, and does not require too much technical experience and professional knowledge. Operators only need simple training to start operation.

2. High bending precision: The bottom-moving bending machine uses the pressure of the upper and lower molds to complete the bending, which can ensure the accuracy of the bending angle and bending lines, thereby ensuring the quality of the processed parts.

Wide range of application: The down-moving bending machine can process various metal plates, such as steel plates, stainless steel plates, aluminum plates, etc., and has a wide range of applications.

3. High production efficiency: The down-moving bending machine adopts electro-hydraulic servo system, which can realize high-speed and high-precision bending processing and improve production efficiency.

-

Professional MG-3512 Up-acting Hybrid CNC Press Brake Supplier-RagosMG-3512 Up-acting Hybrid CNC Press Brake - It has a good effect on the thin plate seriesInquire

-

Best Price MG6020 Up-acting hybrid cnc press brake parameter Supplier-RagosRAGOS MG-6020 model panel benderInquire

-

Factory Price Lower Drive CNC Press Brake MG-8025 model Wholesale-RagosMG-8025Inquire

-

RAGOS MG5016 model panel benderRAGOS MG-5016 panel benderInquire

-

RAGOS MG 1003 Lower Drive Power Press Brake MachineMG-1003 RAGOS MG1003 MODEL PANEL BENDERInquire