RAGOS Panel bender

flexible intelligent multi-edge bending machines.

The press brake machine series is available in a wide range of types and specifications.Well-chosen in material, fine in workmanship, excellent in quality and favorable in price, Ragos's press brake machine is highly competitive in the domestic and foreign markets.

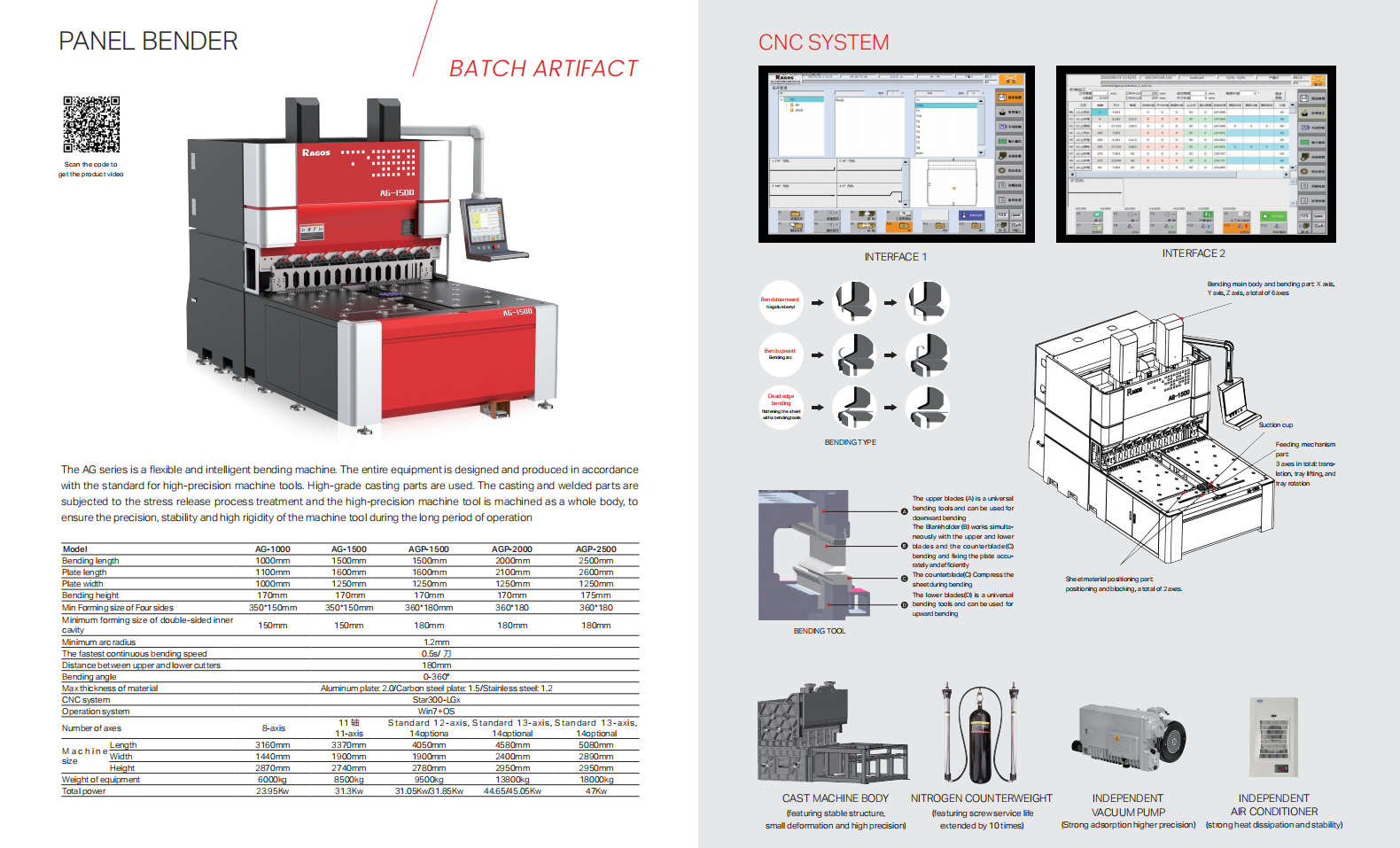

Product model:AG1000 AG1500 AGP1500 AGP2000 AGP2500

Introduction:

Panel benders are a versatile and efficient solution for manufacturers looking to streamline their panel bending operations. With the ability to perform multiple tasks in one setup, panel benders offer a range of benefits, including increased efficiency, precision, and flexibility. In this product detail introduction, we will explore the key features and benefits of panel benders and why they are an essential tool for modern manufacturing.

High Efficiency:

Panel benders are designed to improve efficiency by performing multiple tasks in one setup. This means that manufacturers can reduce the number of setups required to produce a panel, saving time and increasing productivity. Additionally, many panel benders are equipped with automation features, such as robotic arms, that can perform tasks such as panel loading and unloading, reducing the need for manual labor and increasing efficiency.

Precision:

Panel benders are highly precise machines that can achieve a high level of accuracy when bending panels. This results in consistent and accurate bending of panels, reducing the need for rework and waste. Additionally, many panel benders are equipped with sensors and feedback systems that can detect errors and make adjustments in real-time, ensuring that panels are bent to the correct specifications.

Flexibility:

Panel benders are versatile machines that can accommodate a wide range of panel bending applications, including complex shapes and multiple bends. This means that manufacturers can use a single machine to produce a variety of panels, reducing the need for multiple machines and increasing flexibility.

Automation:

Many panel benders are equipped with automation features, such as robotic arms, that can perform tasks such as panel loading and unloading. This reduces the need for manual labor and increases efficiency, allowing manufacturers to produce more panels in less time.

Reduced Setup Time:

Panel benders can be equipped with tool changers, which allow for quick and easy tool changes. This reduces setup time and increases productivity, allowing manufacturers to produce more panels in less time.

Reduced Scrap:

Panel benders can help reduce scrap by ensuring consistent and accurate bending of panels. This reduces the need for rework and waste, resulting in cost savings and increased efficiency.

Improved Safety:

Panel benders are designed with safety features, such as guards and interlocks, to protect operators from injury. This ensures that operators can work safely and efficiently, reducing the risk of accidents and injuries.

Integration:

Panel benders can be integrated with other machines in a production line, allowing for seamless transfer of panels and reducing handling time. This increases efficiency and reduces the risk of errors and defects.

Cost Savings:

Panel benders can result in cost savings due to increased efficiency, reduced scrap, and reduced labor costs. This makes them an essential tool for manufacturers looking to streamline their operations and increase profitability.

Consistency:

Panel benders can ensure consistent bending of panels, resulting in a high-quality finished product. This improves customer satisfaction and reduces the risk of defects and returns.

Conclusion:

Panel benders are a versatile and efficient solution for manufacturers looking to streamline their panel bending operations. With the ability to perform multiple tasks in one setup, panel benders offer a range of benefits, including increased efficiency, precision, and flexibility. Additionally, many panel benders are equipped with automation features, such as robotic arms, that can perform tasks such as panel loading and unloading, reducing the need for manual labor and increasing efficiency. With their ability to improve efficiency, reduce scrap, and increase profitability, panel benders are an essential tool for modern manufacturing.

-

Professional HM-640-6400 Dual servo hybrid cnc press brake parameter picture Supplier-RagosHM-640-6400 Dual servo hybrid cnc press brake parameter pictureInquire

-

Best RAGOS HM-130-3200 Dual servo hybrid cnc press brake parameter SupplierRAGOS HM-130-3200 Dual servo hybrid cnc press brake parameterInquire

-

Oem HM-110-2500 Dual servo hybrid cnc press brake parameter RAGOS Factory Price-RagosHM-110-2500 Dual servo hybrid cnc press brake parameterInquire

-

High Quality RAGOS HM-80-2500 model Down acting hybrid cnc press brake parameter With Good Price-RagosHM-80-2500 model Down acting hybrid cnc press brake parameterInquire

-

Best Quality RAGOS HG-220-3200/4000/5000/6000 model Down acting hybrid cnc press brake parameter Oem-RagosRAGOS HG-220-3200/4000/5000/6000 model Down acting hybrid cnc press brake parameterInquire

-

Factory Price RAGOS NG-6020 model Full electric servo press brake parameter Wholesale-RagosNG-6020 model press brakeInquire

-

Professional MG-3512 Up-acting Hybrid CNC Press Brake Supplier-RagosMG-3512 Up-acting Hybrid CNC Press Brake - It has a good effect on the thin plate seriesInquire

-

NG-3512 Full electric servo press brake High Quality Supplier In ChinaNG-3512 Full electric servo press brakeInquire

-

Best Price MG6020 Up-acting hybrid cnc press brake parameter Supplier-RagosRAGOS MG-6020 model panel benderInquire

-

Factory Price RAGOS HG-170-4000/5000/6000 model Down acting hybrid cnc press brake parameter Wholesale-RagosRAGOS HG-170-4000/5000/6000 model Down acting hybrid cnc press brake parameterInquire

-

Factory Price Lower Drive CNC Press Brake MG-8025 model Wholesale-RagosMG-8025Inquire

-

Best Quality AGP-2000 panel bender Oem-RagosRAGOS NG4015 Model panel bender series parameterInquire

-

Professional AGP1500 panel bender Supplier-RagosAGP1500 panel benderInquire

-

High Quality Professional NG-4015 full electric servo press brake Factory From China-Ragos With Good Price-RagosNG-4015Inquire

-

High Quality NG-2508 Full electric servo press brake With Good Price-RagosNG-2508Inquire

-

RAGOS MG5016 model panel benderRAGOS MG-5016 panel benderInquire

-

RAGOS MG 1003 Lower Drive Power Press Brake MachineMG-1003 RAGOS MG1003 MODEL PANEL BENDERInquire

-

HG-110-4000/5000 model Down acting hybrid cnc press brake parameter High Quality Supplier In ChinaHG-110-4000/5000Inquire

-

Professional AGP-2500 panel bender Factory From China-RagosAGP-2500 panel benderInquire

-

Wholesale press brake machine Plate Roll Bending Machine AG1500 With Good Price-RagosRAGOS AG1500 model press brake machineInquire