Headlines

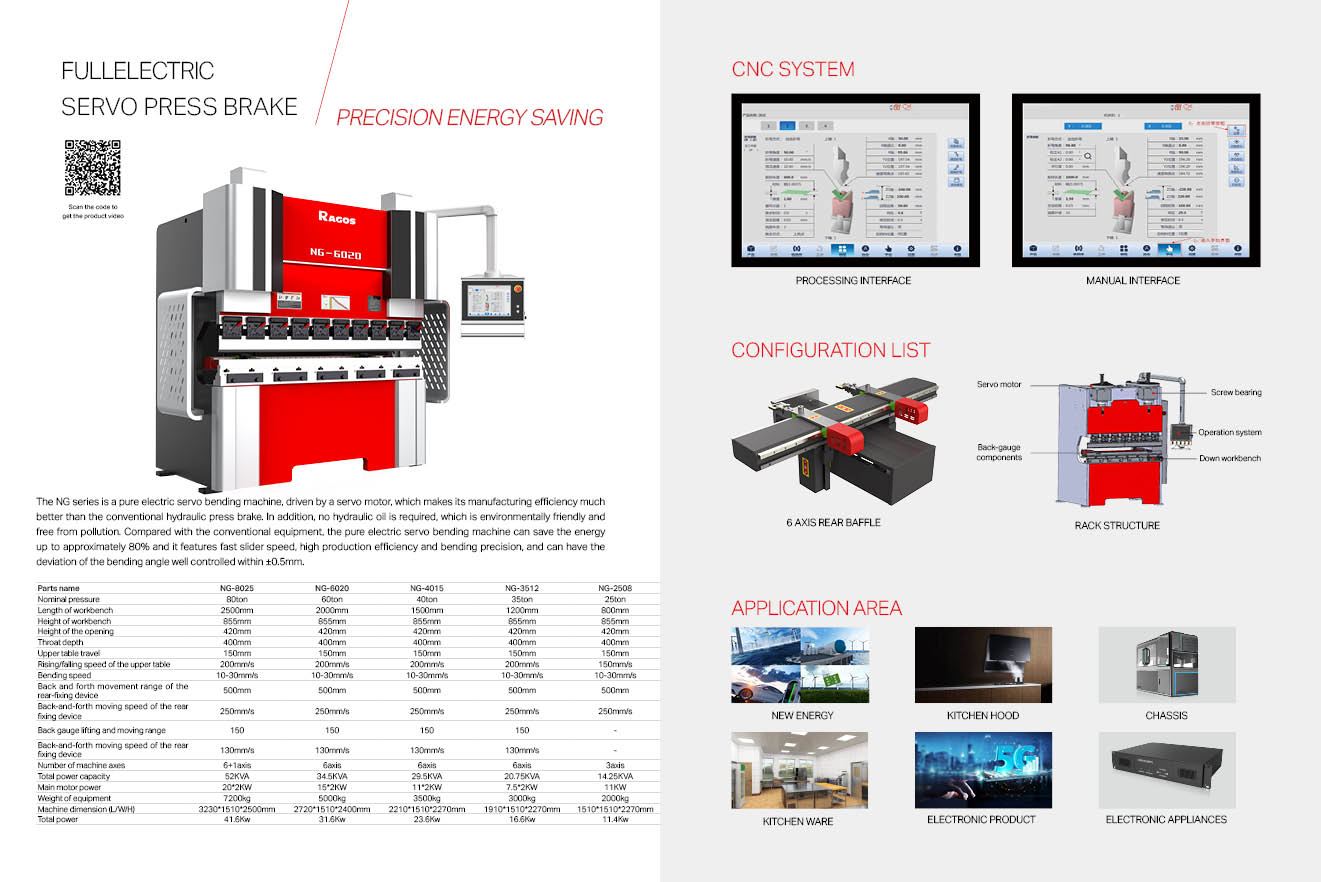

RAGOS NG-2508 PRESS BRAKE

Brand:RAGOS

Payment Type:T/T

Incoterm:FOB,CIF.EXW

Min. Order:1 Set/Sets

Transportation:Ocean

Port:GUANGZHOU-NANSHA,SHENZHEN-SHEKOU

Machine Type:Synchronized

Place of Origin:FOSHAN CHINA

Machinable Material:Stainless Steel, Alloy, Carbon Steel, Aluminum

Additional Features:Machining

Out-of-warranty Service:Video Technical Support, Online Support

Applicable Industry:Machinery Repair Shops, Manufacturing Plant, Other, Building Material Shops, Energy,Amp; Mining

Where To Provide Local Services :Egypt, Canada, Turkey, India, Russia

Showroom Location (in Which Countries Are There Sample Rooms Overseas):Egypt, Canada, Turkey, Russia

Marketing Type:Other

Mechanical Test Report:Provided

Video Factory Inspection:Provided

Core Components:Bearing, Engine, Other, Pressure Vessel

Packaging:Ragos standard export packaging

Certificate:CE

Packaging & Delivery

Selling Units:Set/Sets

Package Type:Ragos standard export packaging

Product keywords:Panel bender,Press brake,cnc bending machine,Dual servo hybird cnc press brake,Down-acting press brake,Up-acting press brake,full electric servo press brake,V-Grooving machine,

## The Advantages of Servo Electric Press Brakes

### 1. Pure Electric Power

The most significant difference between Servo Electric Press Brakes and their hydraulic counterparts is their power source. Servo Electric Press Brakes are 100% electric, utilizing advanced servo motors to generate the required bending force. This eliminates the need for hydraulic oil, reducing environmental impact and minimizing the risk of oil leaks and spills.

### 2. Energy Efficiency

Servo Electric Press Brakes consume up to 50% less energy compared to hydraulic machines. This is achieved through the efficient use of electric motors, which only consume power when actively generating force. Additionally, these motors can recover energy during the deceleration phase, further reducing overall energy consumption.

### 3. Speed and Precision

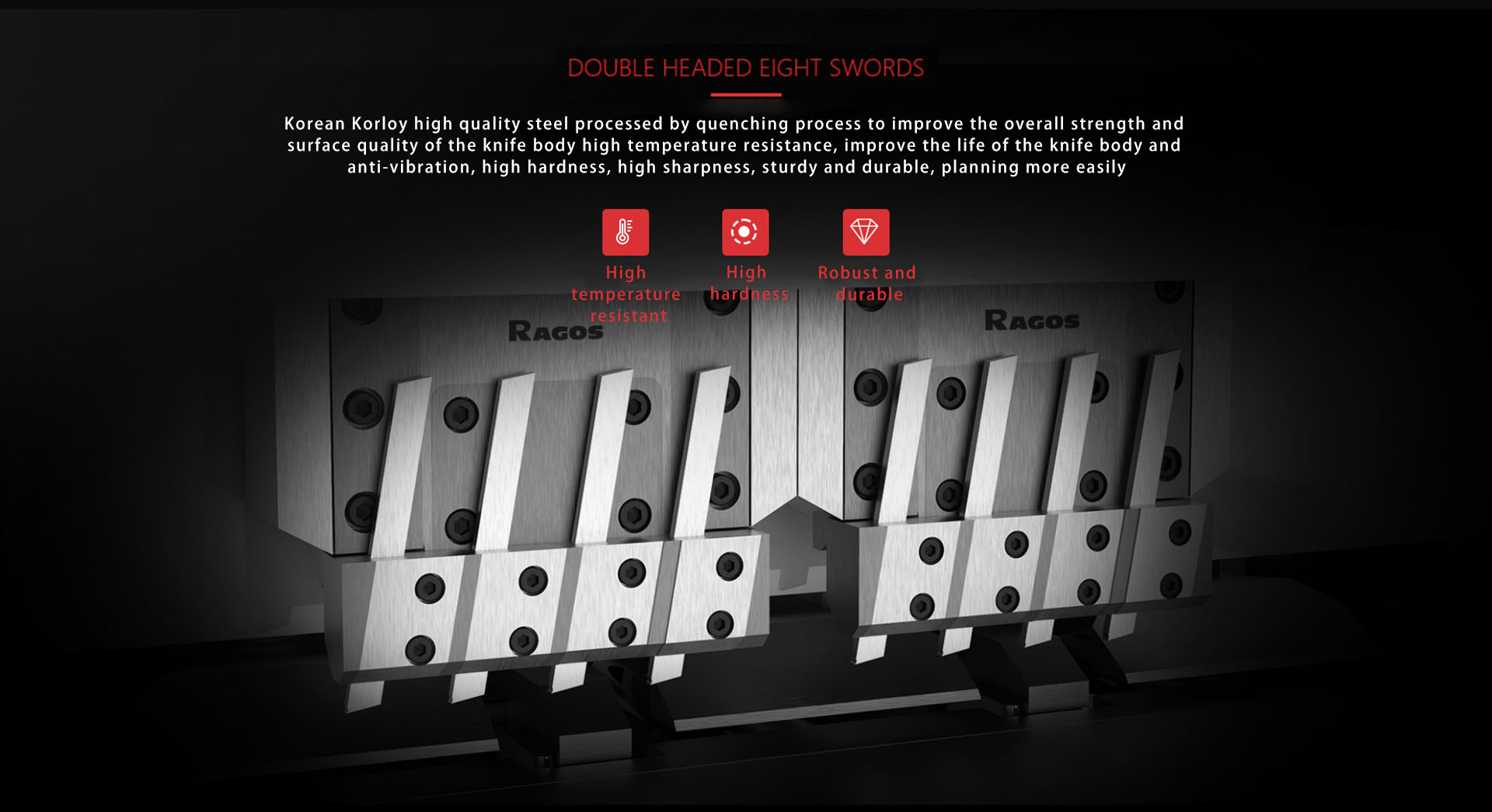

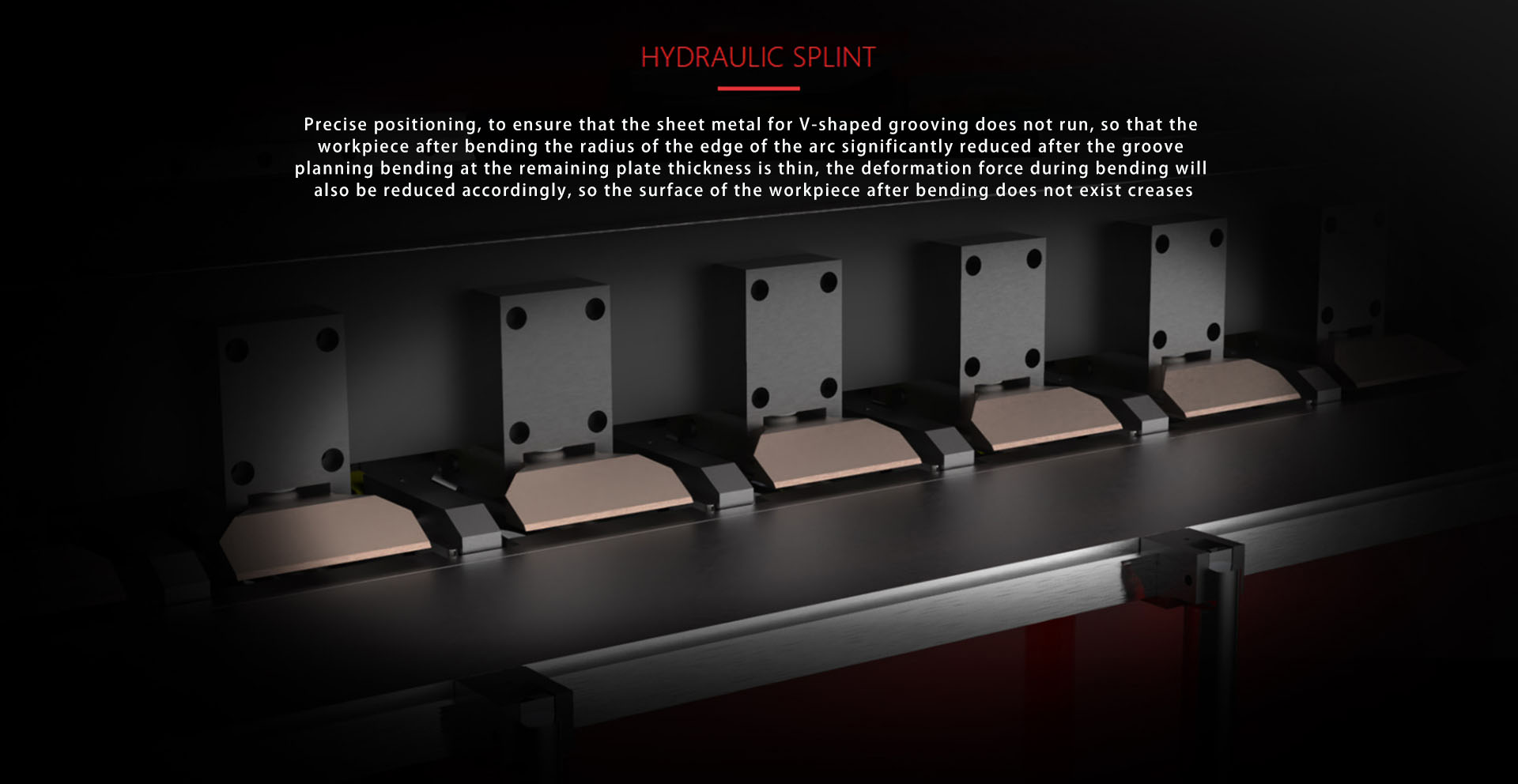

Thanks to their advanced servo motor technology, Servo Electric Press Brakes can achieve up to 35% faster bending speeds compared to hydraulic machines. This increased speed, coupled with the precision of electric motors, allows for higher throughput and improved part quality.

### 4. Noise Reduction

Servo Electric Press Brakes operate with significantly less noise compared to hydraulic machines, creating a more comfortable working environment for operators and reducing noise pollution in the workplace.

### 5. Full Bending Length

With their electric servo motor technology, Servo Electric Press Brakes can achieve the full bending length between side frames. This allows for greater flexibility in the types of workpieces that can be processed, increasing the machine's overall capabilities.

### 6. Reduced Maintenance Costs

The absence of hydraulic components in Servo Electric Press Brakes not only reduces environmental impact but also results in lower maintenance costs. With fewer moving parts and no risk of hydraulic oil leaks, these machines are more cost-effective to maintain over their lifespan.

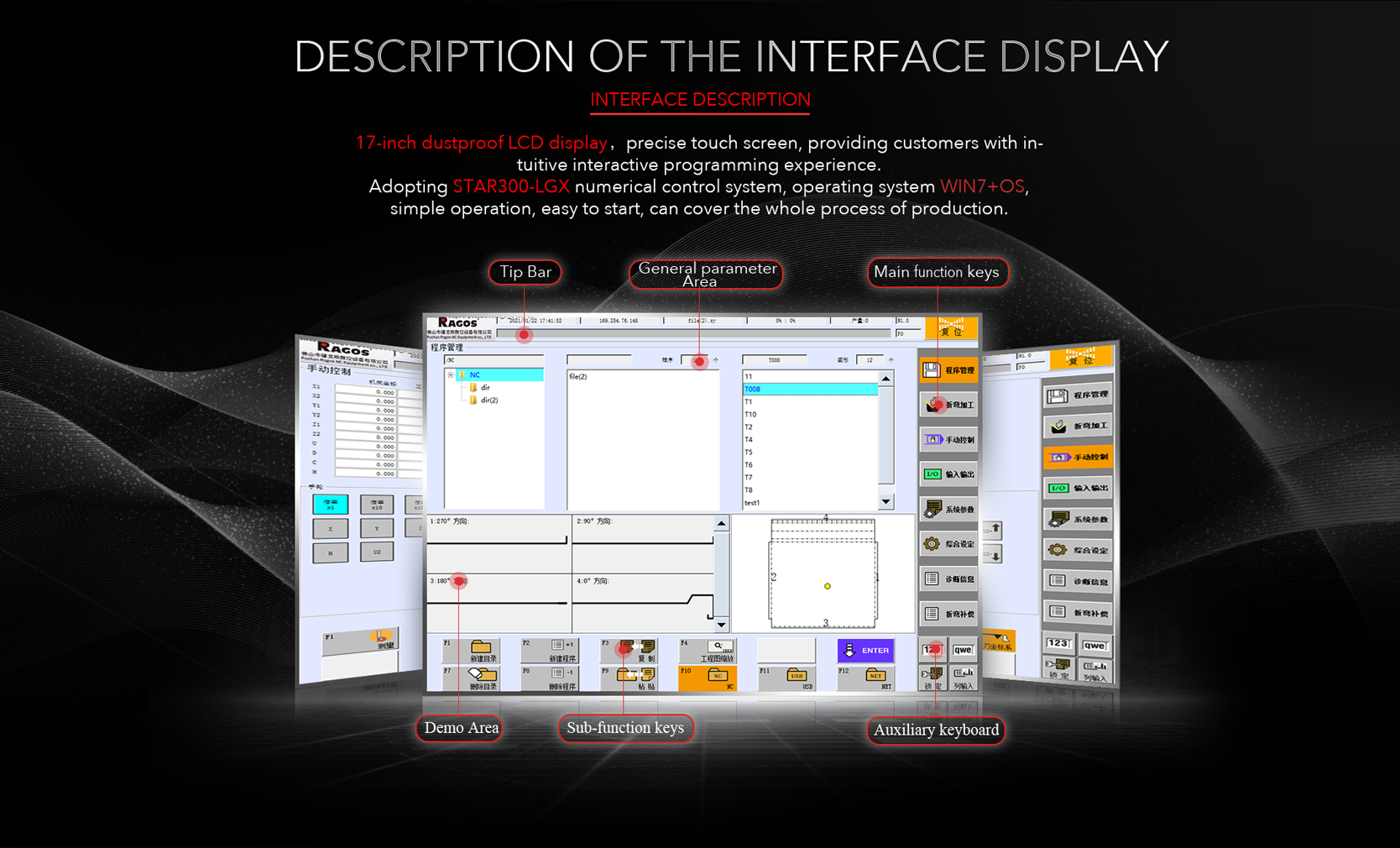

### 7. User-Friendly Interface

Many Servo Electric Press Brakes feature advanced CNC controllers, making them easy to program and operate. This user-friendly interface, combined with fast and accurate puncher and die clamping and multi-axis back gauge systems, ensures efficient and precise sheet metal bending.

## Applications of Servo Electric Press Brakes

Servo Electric Press Brakes are suitable for a wide range of industries that require precision sheet metal bending. Their flexibility and efficiency make them ideal for applications such as:

- Aerospace

- Automotive

- Construction

- Electronics

- HVAC

- Medical equipment manufacturing

- Metal fabrication

- Renewable energy

##Conclusion

As the manufacturing industry moves towards more sustainable and efficient practices, Servo Electric Press Brakes are poised to become the go-to choice for sheet metal bending. With their numerous advantages, including lower energy consumption, reduced maintenance costs, and enhanced productivity, these machines represent a significant leap forward in green manufacturing technology. Manufacturers who embrace this eco-friendly innovation can expect to see significant cost savings and improved efficiency, all while minimizing their environmental footprint.

Copyright © 2025 Foshan Ragos NC Equipment co.,LTD. (panel bender) | All Rights Reserved

We are here to help you! If you close the chatbox, you will automatically receive a response from us via e-mail. Please be sure to leave your contact details so that we can better assist you.