The writing of the nc machine tools is based on a good pace, is based on wind-induced directly affects the process of nc programming can deformity, machining machine can reach the drawings.

It need to staff the action pace, not only should control the pace of the working principle and structure of nc machine tools, and on top of the machine processing technology.

Pace part 1, collect the following five aspects: analysis of the whole machine termination process analysis and processing, mathematical processing of parts, write the inventory machine pace, debug, and modify the pace and implement.

Programming a CNC punch press.

Analysis of the whole machine: no matter what any one machine processing, its first response figure termination analysis of the machine.

Much of the machine processed in the shape of a comprehensive, size, components, materials and heat treatment of the premise, for the treatment process.

2.

Punching process analysis and processing: process analysis is the process of action, deep throat punch collect roughing and choice of lamps and lanterns, 1 part of the cutting tool choice to install and heat treatment, etc.

Origin of coordinates to must have a choice of nc machining process in cutting point and feeding to routing, etc.

One must handle pace: behold choice into CNC turret bed and fixture, cutting tools and cutting second, the amount of choice.

B: set up the workpiece coordinate system is bound to the workpiece coordinate system and between the machine coordinate system, and the processing precisely,

press brake machine manufacturer to necessarily tool motion track of how many shapes do hold to, out of shape tolerance he found.

Is bound to be a knife and tool change point of processing centers: the knife point nc machine tools, machining tool change point, cutting tool point of departure is roughly similar points.

This is a choice, cutter ladder calculations first, second, if the knife point and workpiece with one set of safe isolation distance, but it is not allowed to ATC cutting tool and workpiece collisions, the beginning, you should be careful in cutting point, and artifacts from the distance is not too big, cause too much air viewing, cutting tool and the workpiece should maintain the peace of the fair.

Zhengzhou press brake machine nc machine tool, please be careful of differences it's resolution and change knife point is not 1 sample.

For business owners unsure of how to effectively incorporate new technology into our Solution, life may have just become a little easier.

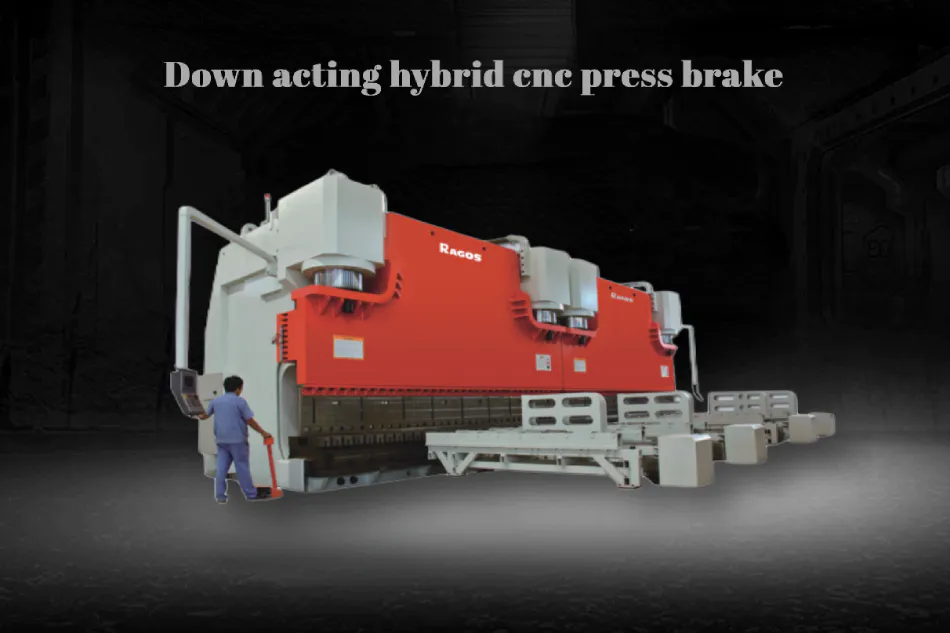

We are proud to be one of the largest suppliers out there. You will love what we offer for your Solution solution. Check our website at Ragos

Press Brake Machine or call to talk to our customer service department with any questions you may have.

If you need any help in Solution small press brake, Foshan Ragos NC Equipment co.,LTD. can help you. We provide the best in class. Our design and services will enable you to create the ideal room that you have always wanted!