1, first time should be controlled machine physical read the instructions carefully before using, and then use.

2, small single

press brake machine work (only in a certain direction

See the arrow on the handwheel or shield)

, be counterclocked, so as not to damage parts.

In pressure adjustment especially need to pay attention to, don't neglect.

3, belt dancer: by mechanical and electrical floor two adjusted by the adjusting nut.

Adjusted the note after the lock.

4, no power supply on hand presser, v-belt should be removed, in order to reduce resistance and wear.

But don't put the big pulley is removed, because the big pulley have a function of the flywheel energy.

5, electric pressure for a little while to turn the handle on the wheel down, so as to avoid injury during operation.

6, whether manual or electric compressor, the compressor should make up in the core rod before initiating the upward position and then start again.

If under the condition of the plate in the down position on the start, just beginning to start into the mold piece, at this time due to the speed of the machine is not up inertia small, easy to cars.

(

Namely into the upper press brake machine die due to the resistance of pills to death, after the machine stop running.

Due to large load, and cars are often damage the machine or burning motor)

。

7, after the top car (1) the disposal methods in electric cars were happen, immediately shut off the power, so as to avoid burning motor.

2 cars lighter, lever changed hands on the wheel to make available to rush through the dead point (

But be counterclocked, lest feeder repeated loading, cause more serious and cars)

。

(3) serious and cars, unscrew the connecting rod lock nut rush on moral core rod, make its rise to reduce the pressure, turn the handwheel to pills out again.

And then readjust the tablet hardness.

8, in the process of the tablet must often check the tablets quality (

Tablet weight, hardness, surface finish, etc. )

, timely adjust.

9, in front of the tablet ingredients granulating process for tablet has a great influence.

Such as medicine and material, filler, adhesive and other accessories granulating formula (

FenZi condition, elastic particles, the proportion of powder, water content, etc. )

, directly affects the quality of tablets.

And often due to improper ingredients granulating and cannot piece, even damage the machine.

Therefore, this machine can not be used in the semisolid or wet or no particles very fine FenZi tablet.

In use that the pressure has the quite big pressure piece or not is still piece but appear too loose, the layer, the phenomenon such as debris, pitting, off powder.

Should from the ingredients and so on to find out reasons and addressed.

Must not blindly increased pressure adjustment, so that damage to the machine.

In addition, some medicines tablet hardness of though is not big, but has a certain toughness, its a fall off a city is not bad,

Usually from 1 -

1.

Height 2 meters off the ground not broken)

, so should be to meet the demand of the transportation custody for degrees don't single from the hardness, in order to avoid pressure stress, damage to the machine.

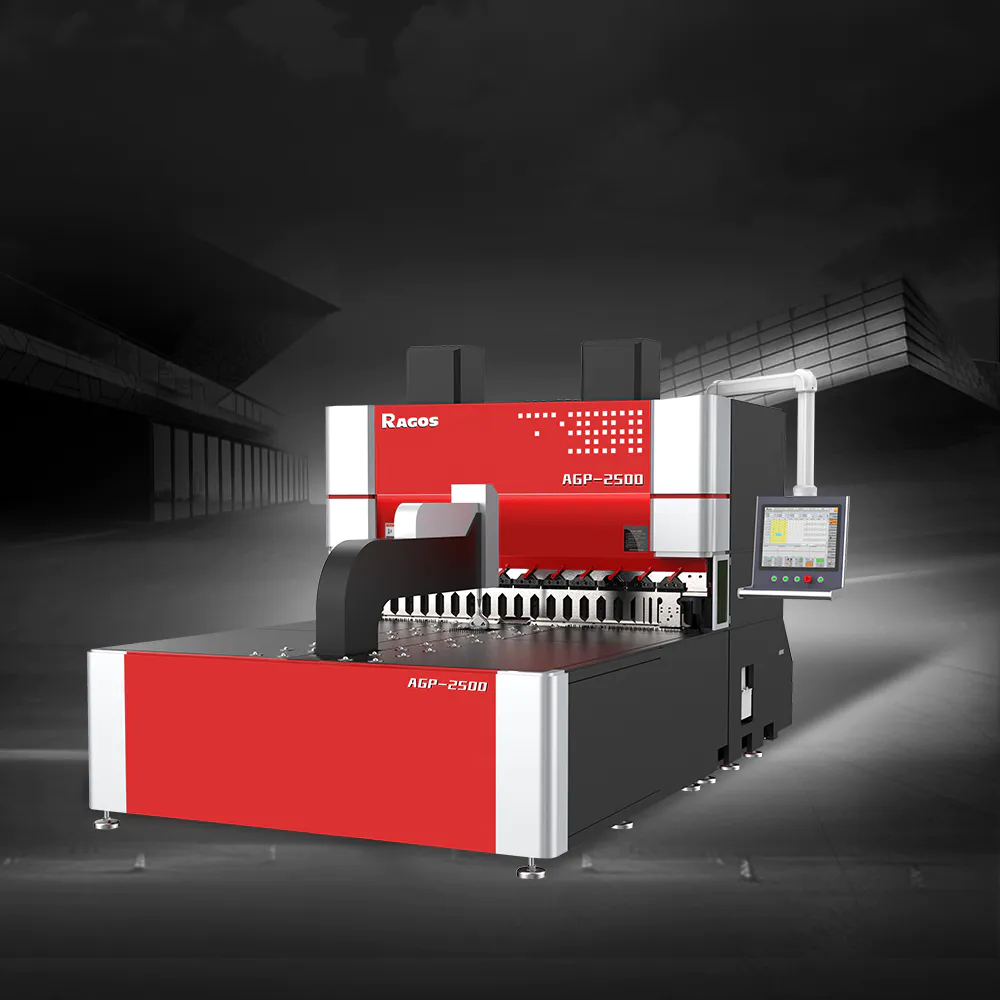

Solution are among the best and the long known , which plays an essential part in automatic manufacturing.

As a global Solution company, we take on some of the world’s biggest Solution challenges. Foshan Ragos NC Equipment co.,LTD. have a whole series of sheet metal equipment Solution that can solve your Solution problem in an effective manner. Check it at Ragos

Press Brake Machine.

You can get more information from Ragos Press Brake Machine for on sale. welcome to visit us and send your inquiry!