HG Series has the most advantage in thick or long plate. It brings best quality, simple operation and an attractive price-performance ratio. This means you can save the cost to make more profit within precise results as well as the highest safety standards.

HIGH

SPEED WIRE

CUTTING EDM

DETAILS

TAPER

MEASURING HEAD

Small taper adjustment device, the

largerst taper adjustable to 6°/80mm

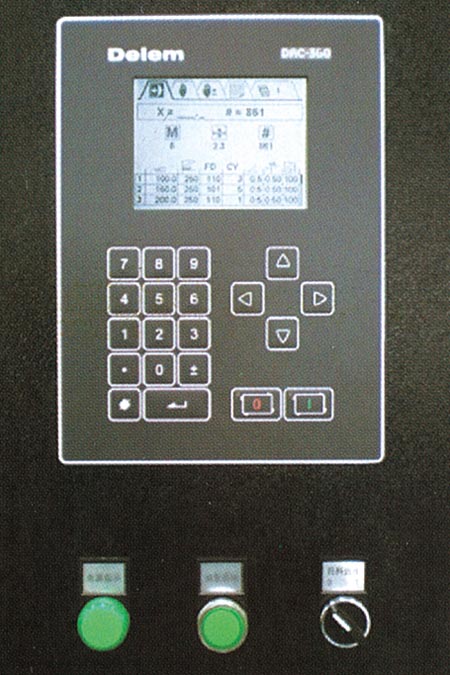

CONTROL PANEL

It seems simple and clear ,use-friendly

control.

MOVEMENT

WIRE SYSTEM

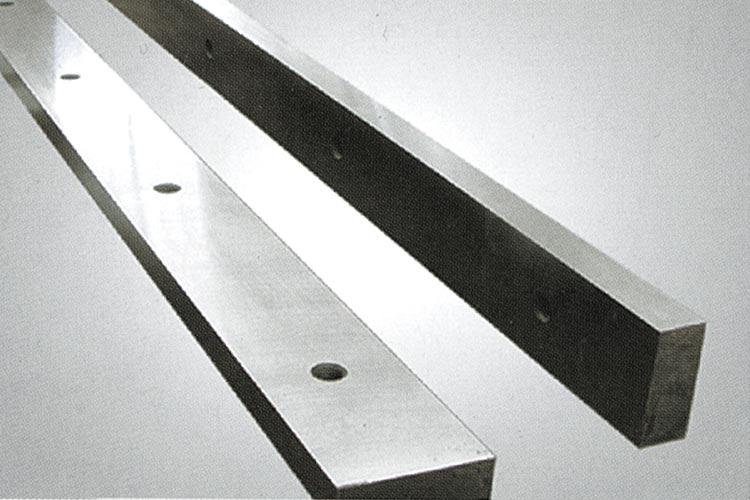

Use stainless steel surface , long

service life.

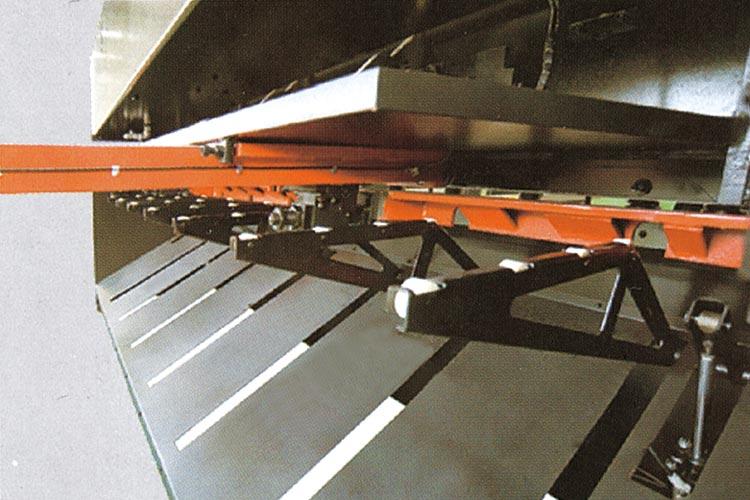

WORKBENCH

It's a flexible processing auxiliary

equipment which suitable for all kinds

of shapes.

Electric system

All the parts are made of brand

products,quality assurance, low

failure rate.

wire edm machine -- Parameter:

| Model | Working table size | Travel of working table | Maximum cutting thickness | Taper machining | Maximum load weight | Optimum surface roughness |

| DK7725 | 400x579mm | 250x320mm | 300mm | 3-6°/80mm | 300kg | Ra<2.5um |

| DK7732 | 680x440mm | 320x400mm | 400-500mm | 3-6°/80mm | 400kg | Ra<2.5um |

| DK7735 | 740x470mm | 350x450mm | 500mm | 3-6°/80mm | 450kg | Ra<2.5um |

| DK7740 | 760x540mm | 400x500mm | 400-500mm | 3-6°/80mm | 600kg | Ra<2.5um |

| DK7745 | 920x540mm | 450x630mm | 400-500mm | 3-6°/80mm | 750kg | Ra<2.5um |

| DK7750 | 1147x655mm | 500x800mm | 600-800mm | 3-6°/80mm | 800kg | Ra<1.0um |

| DK7763 | 1380x800mm | 630x1000mm | 600-800mm | 3-6°/80mm | 2000kg | Ra<2.5um |

| DK7780 | 1600x1000mm | 800x1200mm | 400-800mm | 3-6°/80mm | 1500kg | Ra<2.5um |

| DK77100 | 1820x1180mm | 1000x1400mm | 1000mm | 3-6°/80mm | 4000kg | Ra<2.5um |

| DK77120 | 1340x2000mm | 1200x1600mm | 600-1000mm | 3-6°/80mm | 7000kg | Ra<2.5um |

workpiece

wire edm machine -- Optional:

1.Taper cutting appliance. (±3°, ±30°)

2.Straight guide rail

3.Protective cover

4.high speed controlling system

5.medium-feeding wire controlling system

6.integrated machine appliance

7.autocut system,HL system,WinCut system,HF system

8.DK77 Series can choose the Cutting Magnets

9.DK77 Series can choose the Cutting Aluminium

Features of the cnc wire cut edm machine:

Special supporting design of the machine with high strength and heavy loading capacity.

The machine uses the V-shape long span and long guiding rail structure lined with steel which helps the stability.

The feeding wire part of the machine uses the driving system of gearwheel with lower noise and longer life.

The maximum diameter of molybdenum wire is <= 0.25mm. The wire tube uses the chroming material with good

wear resistance.

The cutting accuracy of all direction is less than 0.01mm. Use high precision ball screw, which has high

transmission efficiency,

good positioning accuracy, long life and well synchronization performance. Use the high precision guide rail with

high strength, heavy loading capacity and low resistance. High stability of the machine. The failure rate is almost 0.

Apply beakless soft reversing, which prolongs the service life of reversing key. All the machine applies the high

precision guide wheel appliance to enhance the accuracy of cutting. All the machine-tools use the laser

interferometer to test the accuracy. (Renishaw Laser Test System from the great Britain).

PLYWOOD PACKING

| Model | Cut thickness | Cut length | Shear angle | Back gauge range | Motor power | Machine dimensions | Machine weight | ||

| Unit | mm | mm | ° | mm | kW | mm(L/W/H) | kg | ||

| LGS-6×2500 | 6 | 2500 | 1.5 | 20~750 | 11 | 3200 | 1750 | 2000 | 6300 |

| LGS-6×3200 | 6 | 3200 | 1.5 | 20~750 | 11 | 3900 | 1800 | 2050 | 7500 |

| LGS-6×4000 | 6 | 4000 | 1.5 | 20~750 | 11 | 4700 | 1850 | 2100 | 8300 |

| LGS-8×2500 | 8 | 2500 | 1.5 | 20~750 | 15 | 3250 | 1800 | 2100 | 7500 |

| LGS-8×3200 | 8 | 3200 | 1.5 | 20~750 | 15 | 3950 | 1850 | 2150 | 8200 |

| LGS-8×4000 | 8 | 4000 | 1.5 | 20~750 | 15 | 4750 | 1900 | 2200 | 9500 |

| LGS-12×2500 | 12 | 2500 | 2 | 20~1000 | 18.5 | 3300 | 1850 | 2150 | 9000 |

| LGS-12×3200 | 12 | 3200 | 2 | 20~1000 | 18.5 | 4000 | 1900 | 2200 | 11500 |

| LGS-12×4000 | 12 | 4000 | 2 | 20~1000 | 18.5 | 4800 | 2000 | 2300 | 14500 |

| LGS-12×6000 | 12 | 6000 | 2 | 20~1000 | 22 | 7000 | 2500 | 3000 | 32000 |

| LGS-16×2500 | 16 | 2500 | 2.5 | 20~1000 | 30 | 3400 | 2000 | 2500 | 13500 |

| LGS-16×3200 | 16 | 3200 | 2.5 | 20~1000 | 30 | 4100 | 2200 | 2600 | 15500 |

| LGS-16×4000 | 16 | 4000 | 2.5 | 20~1000 | 30 | 4900 | 2300 | 2700 | 20000 |

| LGS-16×6000 | 16 | 6000 | 2.5 | 20~1000 | 45 | 7000 | 2500 | 2850 | 38000 |

| LGS-20×2500 | 20 | 2500 | 2.5 | 20~1000 | 37 | 3500 | 2200 | 2700 | 18000 |

| LGS-20×3200 | 20 | 3200 | 2.5 | 20~1000 | 37 | 4100 | 2300 | 2850 | 24000 |

| LGS-20×4000 | 20 | 4000 | 2.5 | 20~1000 | 45 | 4900 | 2500 | 3000 | 27000 |

| LGS-25×2500 | 25 | 2500 | 3 | 20~1000 | 45 | 3600 | 2500 | 3000 | 22000 |

111

111

111

Copyright © 2025 Foshan Ragos NC Equipment co.,LTD. (panel bender) | All Rights Reserved

We are here to help you! If you close the chatbox, you will automatically receive a response from us via e-mail. Please be sure to leave your contact details so that we can better assist you.