Using free bending, bending radius of concave die openings from 0.

156 times.

In the process of bending, die opening distance should be 8 times the thickness of the metal material.

For example, using 16 1/2 inch opening from forming the gauge low carbon steel, parts of the bending radius is about 0.

078 inches.

If you almost small bending radius to the thickness of the material, you must make a bottom die forming.

However, a bottom die forming the required pressure about four times larger than the free bending.

If the bending radius is less than the thickness of the material, the front-end should be used in

press brake machine radius is smaller than the thickness of the material, and turn to stamping bending method.

So, it is need to 10 times the free bending stress.

In terms of free bending, convex die and concave die according to the 85 & deg;

Or less than 85 & deg;

Processing (

A bit as well)

。

Using this set of mold, punch and die in the gap at the bottom of the stroke, and compensate the springback and keep the material & 90 deg;

Around the bend.

Usually, free bending die in new bending machine to produce the springback Angle & le;

2°

Begin from 0, bending radius equal to the concave die.

156 times.

For a bottom bending die, die Angle generally is 86 ~ 90 & deg;

。

In the bottom of the stroke, intensive should have a slightly larger than the material thickness of the gap between.

To improve the forming Angle, because a bottom die bending large tonnage (

About four times that of free bending)

And reduce the bending radius range usually cause the springback stress.

Stamping bending with a bottom bending die are the same, just put the front end of the punch processing became the bending radius of the need, and intensive clearance is less than the thickness of the material at the bottom of the stroke.

Due to exert enough pressure (

Is about 10 times of free bending)

Forcing press brake machine front contact material, basically avoid the springback.

In order to select the minimum tonnage specifications, the best is greater than the material thickness of the bend radius to plan, and as far as possible by free bending method.

When bending radius is bigger, often do not affect the quality of the pieces and its use in the future.

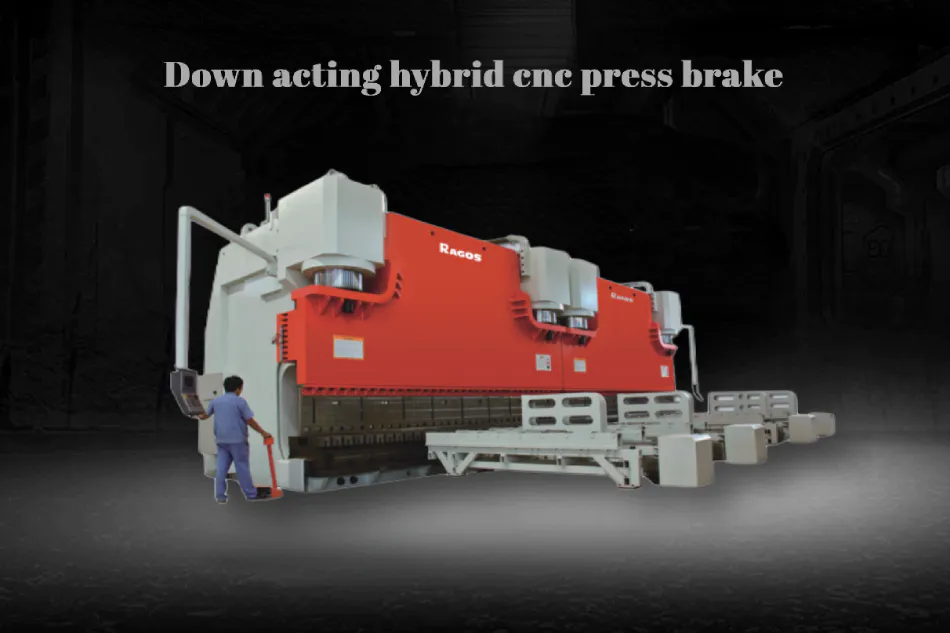

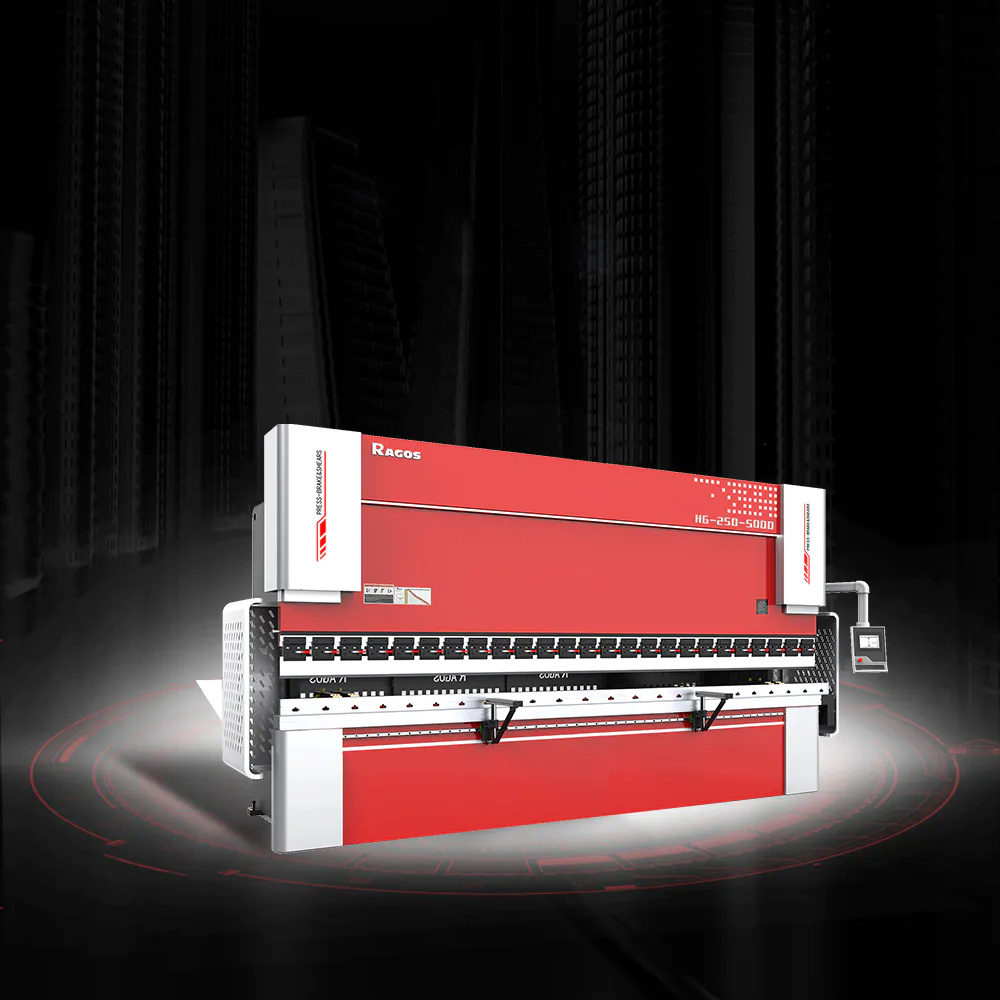

Foshan Ragos NC Equipment co.,LTD. shows how effective market design can encourage participation, reduce gaming, and aggregate information, in order to improve liquidity, efficiency, and equity in markets.

No, this isn't a wonder product and it won't be likely to change your life but it will give your hydraulic shearing machine a kick and bring the extraordinary to the every day. give it a shot at Ragos

Press Brake Machine.

Once we have a good idea of how Solution can satisfy customer’s needs, consider whether we should create a skill for their demands.

Innovative technology helped us produce a strong, reliable product as Solution for customers, offer superior quality and dependability to our customers, and scale at a quicker pace.