From the perspective of a small bending machine working state, it is under external load and speed of work is not fixed, but with the extension of time changing.

In view of this, the actual bending machine hydraulic circuit, also along with the load and the speed of executive components must be constantly changing requirements into account.

In order to meet the requirements, small bending machine is commonly used pressure type throttling speed control circuit and the two kinds of volumetric speed control circuits, the former is by changing the size of the flow area flow control component in a circuit, to control flow execution component, or the execution component flow of traffic, eventually rise to adjust the speed, the purpose of throttling loss and heat produced by it is small and high efficiency.

While the latter is by changing the loop variable displacement pump or motor, to change the movement speed of executive components, no overflow loss and throttling loss due to the process, and work stress changes over load, so the advantages of high efficiency, small heat.

Bending machine principle of work is not difficult to understand, is by the conductor coil electricity, then the gravitational pressure plate, so as to realize the clamping plate between the pressure plate and the base, and finally achieve the goal of meet the demand of various artifacts.

But seemingly simple process requires cooperation between the parts to give full play to its due effect, any part is not in conformity with the requirements, the operation will be affected.

Bending machine is a kind of composed of multiple components equipment, first mentioned is synchronous system, it contains a torsional axis, swing arm, joint bearings and other parts of synchronous mechanism, a reliable, stable performance and high precision of synchronization.

Followed by the slider part, besides is to adopt hydraulic transmission, it is by the sliding block, the structure of the oil cylinder and the mechanical stop fine-tuning, make through hydraulic piston drives the sliding block moves up and down.

Keep-off institutions is an indispensable part of the bending machine, the motor drive, through the chain operation to drive the two screw synchronous movement, numerical control system to control the size of block.

The last part of the workbench, by manipulating button box, make bending machine motor drives the rack and moves, and controlled by the CNC system moving distance.

Even in the same type of bending machine, also can use different types of bending mode, according to the relative position of the die and to distinguish, bending and sole press bending clearance is the most typical two bending modes.

The following will introduce them one by one, will be very helpful.

Is the so-called gap bending, bending machine in the bending process between the upper die and lower die is not pressure, and by adjusting the mold into the depth of the lower die openings for bending Angle of a process you need.

Typically, die into the deeper the lower die, bending machine bending Angle is smaller;

The greater the vice versa.

This ten percent curved way is that you can use the advantages of less forming mould to achieve a variety of angles.

Just what is bending it down?

Is tight when sheet metal is pressed between the upper and lower mould, and need bending Angle and the bend radius of technology, general applicable Yu Zaizhong batch and mass production, processing, the thickness of sheet metal under 2 mm.

Should pay attention to is that the pressure of bottom bend work pressure is greater than that of bending clearance work pressure.

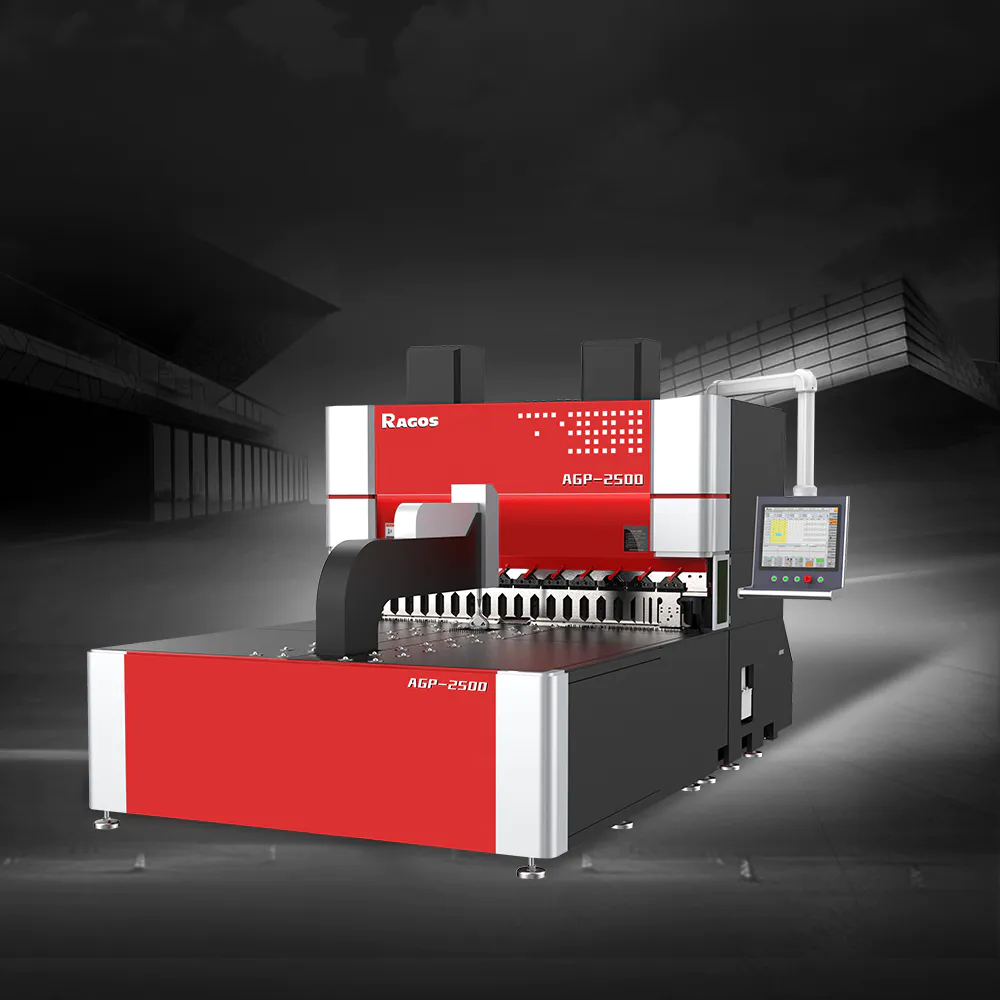

Foshan Ragos NC Equipment co.,LTD. is always trying to better understand the Solution of innovation, so we can help companies lead the industries.

The 21st century is sure to bring more innovation, new services and newer technology, thus new products and services to sell. Foshan Ragos NC Equipment co.,LTD. will continue to shape and lead the markets in which it chooses to compete.

Foshan Ragos NC Equipment co.,LTD. might focus its marketing efforts by highlighting its end product—improved technology and increased profits—not its producing methods.