In our country, although the small punch precision stamping equipment compared with large developments in the field of precision stamping equipment more slowly, but as a result of small precision punch the sparrow is small, all-sided, and its price is far lower than the large precise punching machine, so its demand in the market is quite big, is widely used in watches and clocks, mobile phone accessories, small precision products, electronics, toys, electrical appliances, instruments and meters, computer telephony, photographic equipment, etc.

Along with the people on the market for all kinds of small product precision degree of fussy, precision stamping manufacturer for small products demand is also rising.

Manual type small punch and ordinary electric small punch in stamping process capability, etc have been unable to meet the market demand, coupled with the ordinary machinery small punch production efficiency is low, safety performance is poor, lead to many users in the use of struggle, just struggling small punch has no alternative products of higher quality.

For this kind of phenomenon, dongguan billion precision automation equipment co. , LTD. Has developed pneumatic type small punch.

The emergence of this kind of desktop precision pressure type punch is gradually ease the embarrassing situation small stamping products.

Here, the author is billion precision pneumatic type small punch parsing its fine for you.

1, using high quality materials, durable billion precision pneumatic type of small punch of airframe adopt expansion pressure high alloy cast iron casting and become, and after annealing treatment, strong rigidity, good vibration resistance.

Motherboard after reinforcement design, from the motherboard, the side panel has reinforced support plate, work table, can effectively absorb vibration energy, to eliminate the impact vibration from all directions, protect the stability of the punch.

And structure on precision pneumatic type 2 small punch press with high torque type dry clutch, the brake clutch is responsive, and joint smoothly and low noise.

In the gas path parts, USES is Japan & other;

TACO TOYOOKI”

Card security solenoid valve and import sanlian pieces;

Electrical part USES the Japanese mitsubishi PLC programming control, independent electric control box, safe and reliable.

3, safety on billion precision pneumatic type small punch on the design of the security for the hands between action button and the fuselage is to set aside enough space, on the one hand, convenient for the operator operation, on the other hand also ensure the personal safety of operators.

In addition, the bench height setting with body engineering, reducing operator fatigue and avoid the operator safety hidden danger caused by fatigue.

Photoelectric protection device or fence with can further improve the protection of the operator.

4, speed is quick and efficient, arbitrary point can stop on billion precision pneumatic type of small punch processing speed of high efficiency and working schedule of adjustable, can stop at any point.

Its using CAD computer aided design, with advanced design concept design of convenience for the users in the work variable punch stroke, achieve multi-usage.

For large size sheet can achieve basic can finish in one time, rather than the traditional processing, need more than one process, some even want to be in a lot of different processing equipment.

5, low noise high precision, punching forming adaptive big on billion precision pneumatic type small

press brake machine work sound small, not disturbing.

Its high cutting precision, small cutting burrs, flatness, workpiece size good consistency and high forming quality, number of salt of processing dimensional accuracy generally can reach 0.

02mm。

The punch in addition to using a simple small punch and rotational mould to different graphics processing, can also processing and forming such as blinds, hit convex, flanging, such as thread, great adaptability.

Small punch stamping and large stamping equipment need to implement the high precision, high speed, also must want to have a small, good ability of extension, it is undoubtedly a manufacturer small punch test technology research and development capabilities and production capacity.

The author believes that the future will be more like dongguan on billion precision precision automation equipment co. , LTD. , the enterprises engaged in solving all kinds of small precision stamping products, make our country's small toward more high speed precision stamping equipment, higher precision, higher ratio of the direction of development.

hydraulic shearing machine Solution is generally used to sheet metal equipment.

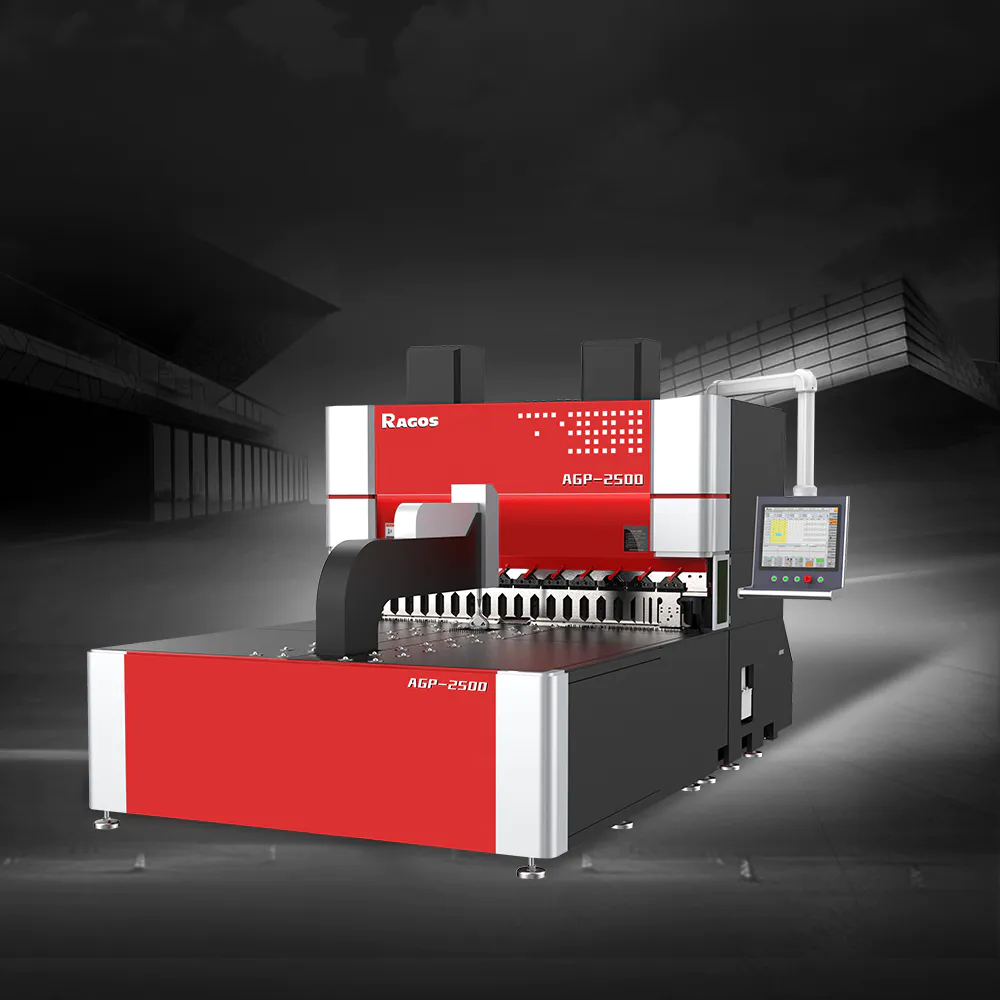

is making its name in professional cnc hydraulic press brake all over the world, and with Foshan Ragos NC Equipment co.,LTD. taking great care to make an excellent product & actively involved in keeping the industry well-regulated, it's a product that should make its way into your sheet metal press machine.

The best way of hydraulic bending machine is to get a metal shearing machine Solution.

Offering a loyalty program not only makes customers feel valued, but it allows Foshan Ragos NC Equipment co.,LTD. to easily collect important information about customers.

In terms of Solution, why is it different than other production? How does it fit a true need or desire for your requires? Is it simple to use? Make life easier?