Wire forming machine is very popular in the field of springs and wire processing equipment, the new equipment it can realize various wire bending forming, but many people know about wire forming machine is not deep, wire forming machine is made up of what structure?

Wire forming machine is introduced in recent years, focusing on the wire bending forming of automation equipment, molding machine can achieve high efficiency, high precision wire bending processing forming, its mainly depend on the feeding structure, straightening, bending forming structure, to cut off the structure of the four basic structure, different structure for different functions: feeding structure: this is wire

metal sheet forming machine transmission wire advancing device, it is to rely on a pair or two pairs of wire feeding wheel pressure, adopting fan incomplete gear transmission feed shaft gear to complete, in order to feed the rotation of the wheel to drive the wire straight line, feed length is feeding wheel circumference, metal forming products expand the length can be determined by the feeding wheel rotation circle;

Straightening structure: the location of the wire forming machine straightening structure between the material and the feed roller, it is composed of two groups of straightening roller, the straightening system is to eliminate the purpose of wire bending deformation of the original, metal wire after straightening can straight into the forming area, so that to improve the precision of the products;

Bending forming structure: distribution after good wire transfer to the bending area, the machine will according to the set in advance good bending forming product bending forming parameters;

Cutting structure: wire after molding, products, cut off is the product of falling last processing, molding product is done through cutting knife cut, this is the final processing wire forming products processing structure;

Above is of several main structure of the wire metal sheet forming machine, is responsible for implementing the wire rod processing molding, and wire metal sheet forming machine and the turn without motor, turn internal model can rotate advanced technology advantage, brings more efficient, higher precision of wire rod processing and forming, can meet the needs in various fields of wire processing molding, welcome the demand of customers contact us!

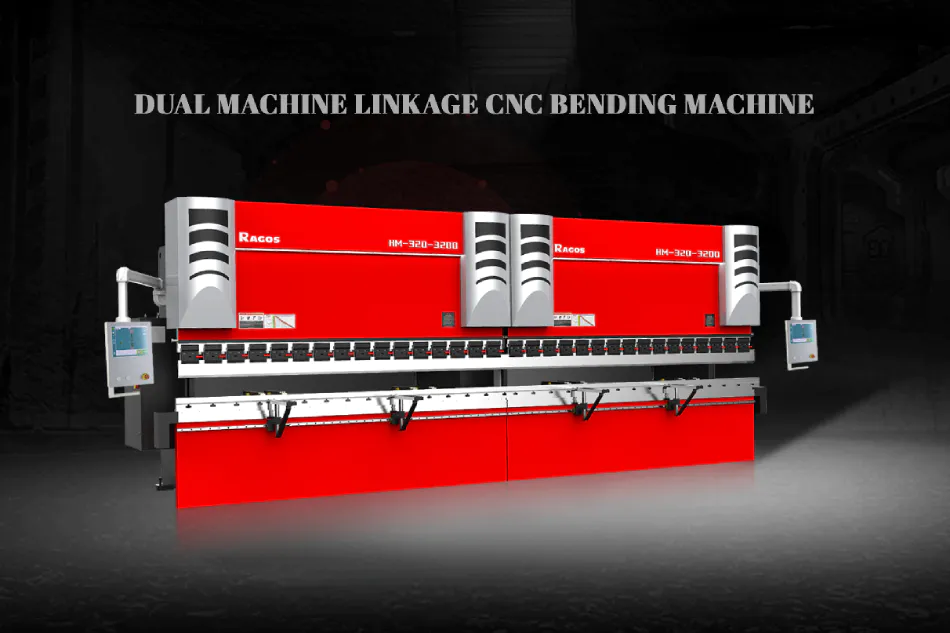

Foshan Ragos NC Equipment co.,LTD. outfits our businesses with Solution because they're relatively affordable and highly customizable.

The best for metal shearing machine is one that works best for your needs and what you can support in your home. Among Foshan Ragos NC Equipment co.,LTD. 's diversified list of products at different price ranges, you will surely find your one with high quality. make your choice at Ragos

Press Brake Machine!

Foshan Ragos NC Equipment co.,LTD. have found that nurturing relationships with clients by welcoming them to our factory can be valuable to all parties.

If you are looking for best product, then here are some product like Solution, hydraulic shearing machine and sheet metal equipment in various styles which will surely meet your demand. Visit Ragos Press Brake Machine to know more!

Regularly improving Solution in accordance with customer feedback is a great way to show your brand listens and cares.