Company Advantages1. This Ragos is sturdily constructed to provide optimum efficiency to the user.

2. Every aspect of the product is excellent, including performance, durability, and practicality.

3. The professional QC team strictly controls the quality of this product.

4. This product will finally contribute to bringing profits for manufacturers. It helps cut expenditures both in labor and energy consumption.

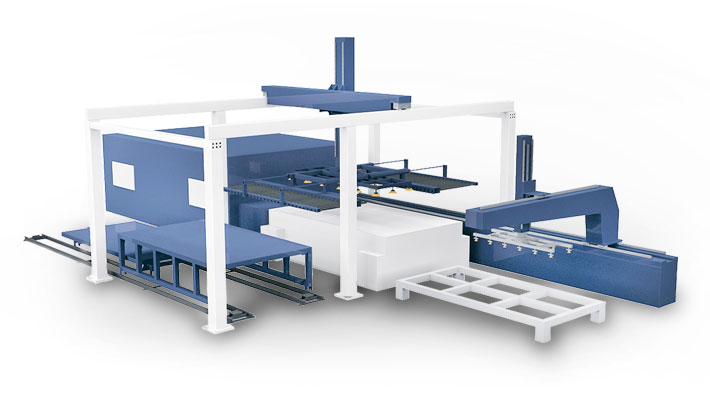

Machine 1

1. No one waits for feeding and discharging, and super-economical production of medium-sized to large-scale batches is completed.

2. Automated plate separation function and double-layer plate detection function;

3. The structure principle of feeding system is to use vacuum suction device as the tool of sheet metal robot to replace traditional manual feeding.

4. Improve work safety, reduce the risk of injury and reduce the intensity of staff.

5. The matching AGC cutting unit can be placed flexibly from left to right to meet the demand of production line and further improve cutting efficiency.

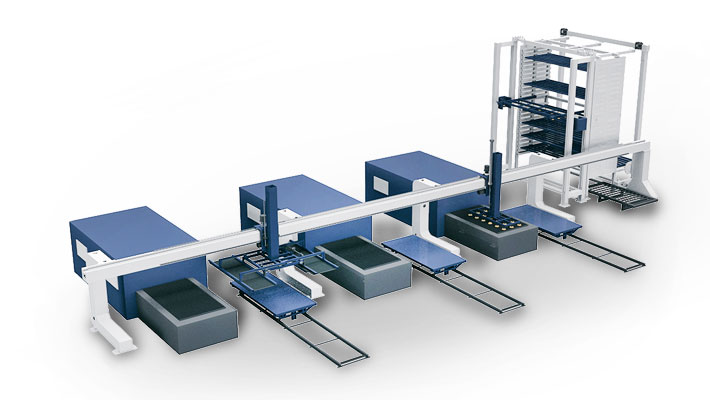

Machine 2

1. No one waits for feeding and discharging, and super-economical production of medium-sized to large-scale batches is completed.

2. Automation detection, plate separation function and double-layer plate detection function.

3. The structure principle of feeding system is to use vacuum suction device as the tool of sheet metal robot to replace traditional manual feeding.

4. Improve work safety, reduce the risk of injury and reduce the intensity of staff.

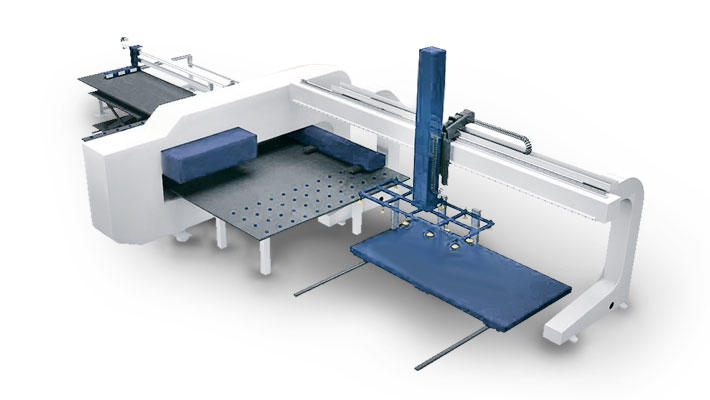

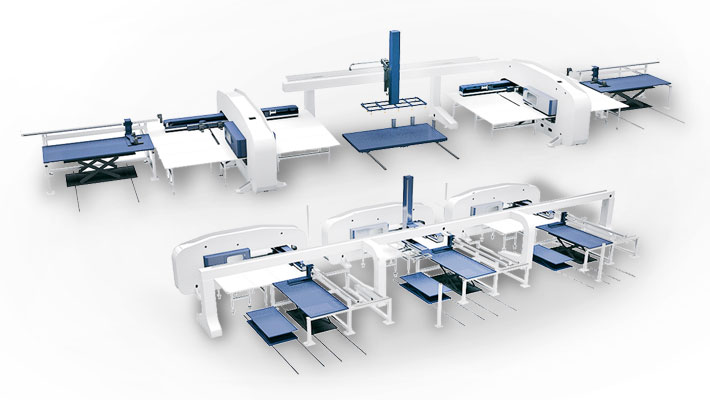

Machine 3

1. No one is waiting to finish the loading and unloading of the workpiece.

2. Plate separation function and double-layer plate detection function.

3. It is equipped with the off-line programming software developed. independently, which improves the operation convenience and efficiency.

4. Modular design makes it possible to match with the mainstream laser cutting machine in the market and customize it according to customers'needs.

5. Vacuum suckers are equipped with one-way globe valves to meet the requirements of different sizes of sheet materials.

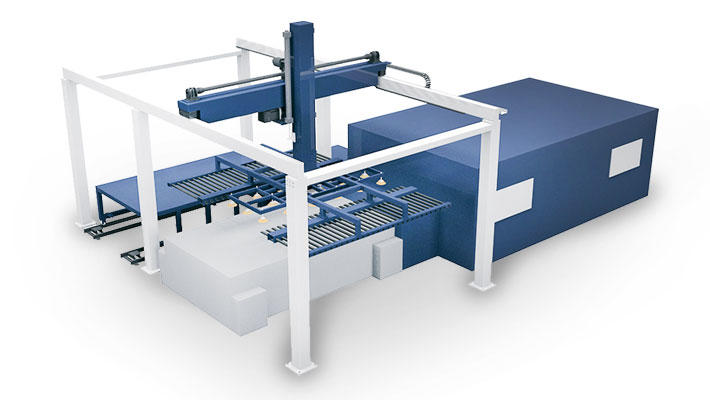

Machine 4

1. No one is waiting to finish the loading and unloading and finishing of the workpiece.

2. Plate separation function and double-layer plate detection function.

3. Equipped with the off-line programming software independently developed by the company, which improves the operation convenience and efficiency.

4. Modular design makes it possible to match with the mainstream laser cutting machine in the market and customize it according to customers'needs.

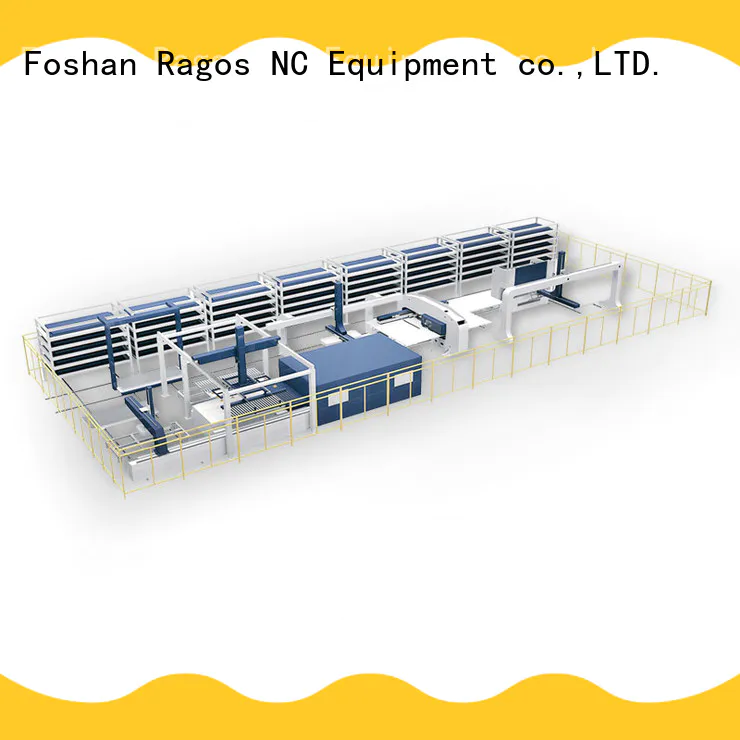

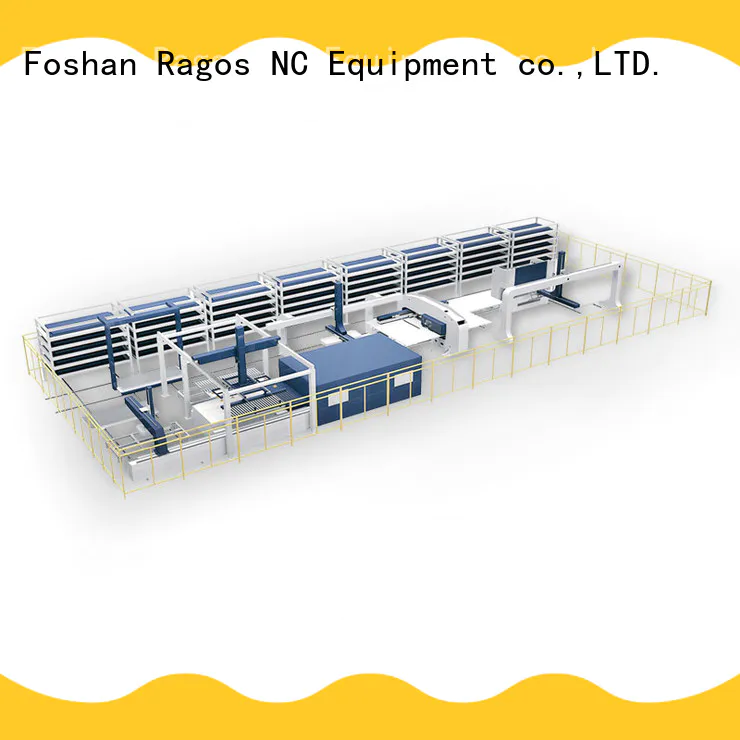

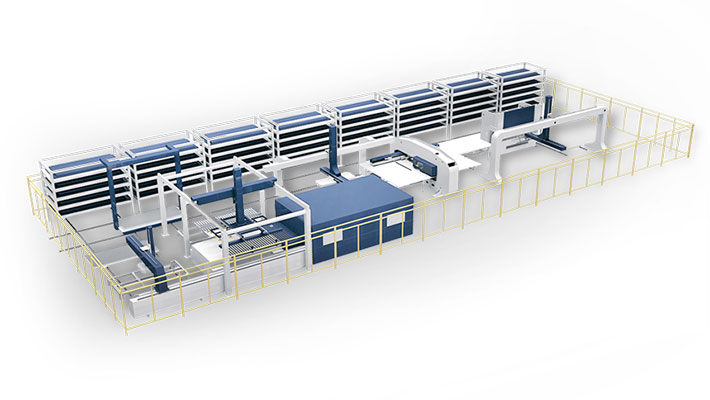

Machine 5

1. Automated unmanned work cycle, with the help of fast loading and unloading function, so that the machine tool has a higher utilization rate.

2. Matching the warehousing units of the whole upper and lower orders, the production rhythm is more optimized.

3. Extensible design, flexible configuration, realizing multiple laser links.

4. Modular design makes it possible to match with the mainstream laser cutting machine in the market and customize it according to customers'needs.

5. Realize multi-species and all-weather unmanned operation.

6. Equipped with roller positioning to reduce the time of edge finding for cutting plate.

Machine 6

外置拉链

1. Save the cost of start-up and equipment investment.

2. Plate separation function and double-layer plate detection function.

3. Compact connection with NC punch press makes space requirement lower.

4. A single NC punch with AGC cutting unit can be equipped with three-dimensional material storehouse to further improve production efficiency.

5. It can be customized according to customers'needs and has expanded ERP and MES systems.

Machine 7

手拉带

1. Save site, time and operation cost.

2. It can be matched with various sheet automation equipment units.

3. Enhance material flow speed to ensure orderly production.

4. Custom-tailored layer height, with expanded ERP, MES system.

Machine 8

车载/家用

1. Automation design is adopted, the machine occupies a small area, and the transportation cost is small.

2. Efficiency: Machines produce more in the same run time.

3. Because of the unmanned operation, the manual operation time is shorter and the machine operation time is longer.

4. With the same investment, stronger productivity, higher productivity, smaller footprint, fewer material storage and semi-finished products.

Ragos brand is a notably popular sheet metal stamping manufacturer.

2. Foshan Ragos NC Equipment co.,LTD. has the latest R&D technology and product experience, leading the industry in a new generation of integrated services.

3. With the aim of constant and cutting-edge innovation, we hope to provide the most innovative products or services to customers to make their advantages stand out. In our business operation, we strive to reduce the emissions, discharges, and wastes that our operations generate and constantly review our production flow. We are acting responsibly and sustainably. We run energy-efficient operations and utilize green chemistry practices and production technologies. We have a commitment to diversity. We will recruit and develop staff to create a diverse, inclusive, and equitable organization and respect and learn from our variety of experiences and ways of thinking.