Recently some netizens reflect the renewable energy and north China electric power university, dean of the school of Dai Mou sexual assault, on the afternoon of 28, north China electric power university through official weibo response.

Maintenance of the punch pneumatic, electrical and smooth mechanism.

Deep throat press pressure: air piping: check whether each line sight of leak occurred;

Air valve and solenoid valve: the appropriate operation, check the air valve and solenoid valve control is normal;

Balance cylinder: see if air leakage, check whether there is a proper smooth;

Whether die cushion: air leakage, check whether to have appropriate smooth, check to see if the die cushion fixed screw loose;

Pressure gauge: press the needle is normal.

press electrical: electrical control: view control, and response operation situation, there is a problem of control, and response operation situation, there are problems handling device to be replaced.

Loose parts tightening, check whether the fuse for the appropriate scale, check whether the insulation of the wire part damage, replace the bad wires;

The motor, check to see if the motor and bracket fixed screw tightening;

Button and foot switch: careful inspection these switches, if have bad immediately replace;

Relay: see the contact friction losses, loose connection of bolt etc. Please carefully the implementation of maintenance.

: smooth smooth clutch air components: eliminate all water, checking their piece of smooth add oil to the right place;

In smooth smooth system: with reference to the present article introduces the smooth areas to carry out the smooth system protection, to see if the smooth line break, wear, to see if parts have holes, break, damage, check the oil level gauge observe whether the oil level height is up to standard.

In the case of normal operation, oiled gear and oil change every three months.

Every six months (

About 1500 hours)

Clean up the oil tank.

Decision to revoke Dai Song yuan, deputy party secretary, dean of renewable energy, related disciplinary problems by the discipline inspection commission 'filing review according to regulation, serious processing.

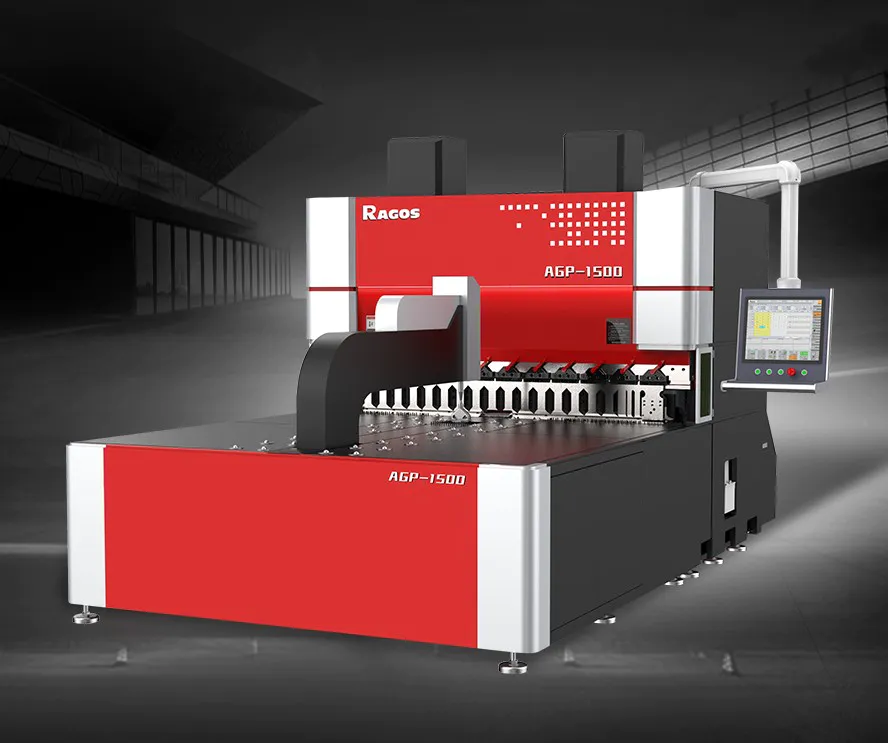

To that end, Foshan Ragos NC Equipment co.,LTD. has successfully built a solid foundation and infrastructure for Solution manufacturing.

We have professional skills and advanced facilities in Solution and many years of experience in small press brake industry. Choose our products at Ragos

Press Brake Machine, and you will get supreme buying experience in return.

Foshan Ragos NC Equipment co.,LTD. are providing this to you at very low cost. Our claims are only based on different feed-backs received from various clients and not based on self-judgment.

Now that Foshan Ragos NC Equipment co.,LTD. has become a leader in the space and have been able to scale appropriately, we are ready to expand to other cities.

There are ample scientific evidence of reducing the risk of sheet metal equipment.