Strictly observe huade machine work safe operating procedures, good wear labor protection articles according to the rules.

Shall be carefully check before they start motor, switch, line and grounding is normal and strong, check the equipment control station, the button is in the correct position.

Check the contact ratio of upper and lower mold and robustness;

Check whether the positioning device meets the requirement of processed.

In has not been on board and the positioning shaft at the origin of state, run back to the origin program.

Equipment starts running 1 & ndash;

2 minutes, skateboard full stroke movement 2 & ndash;

3 times, if found to have abnormal sound or defective should immediately stop, troubleshooting, all rear can normal work.

Should be unified command by 1 person at work, make the operation personnel in close coordination with the feeding suppression of personnel, to ensure that together with the staff members in safe place party must signal bending.

Sheet metal bending must compaction, in case when bending sheet metal cock cuts.

Must cut off power supply when the sheet metal die, after the stop.

Under the change of variable mold opening, not allowed to have any contact with the lower die.

At work, machine tools are not allowed to stand in the back.

It is forbidden to separate sheet metal at one end of the compressive and flexural strength.

Found artifacts or mold during operation, should stop correction, it is forbidden to run with hand correction in case of hurting hands.

Ban fold the ultra thick iron or steel, high alloy steel, square steel quenching far and more than the performance of sheet metal

bending machine sheet metal, so as not to damage the machine.

Check the contact ratio of the upper and lower mould;

Pressure gauge indicates whether conform to the rules.

An exception occurs immediately stop, check the reason and ruled out in time.

Before the shutdown, want to be in on both sides of the cylinder at the bottom of the lower die on placing block will slide down to block.

After exit the program control system, first cut off power supply.

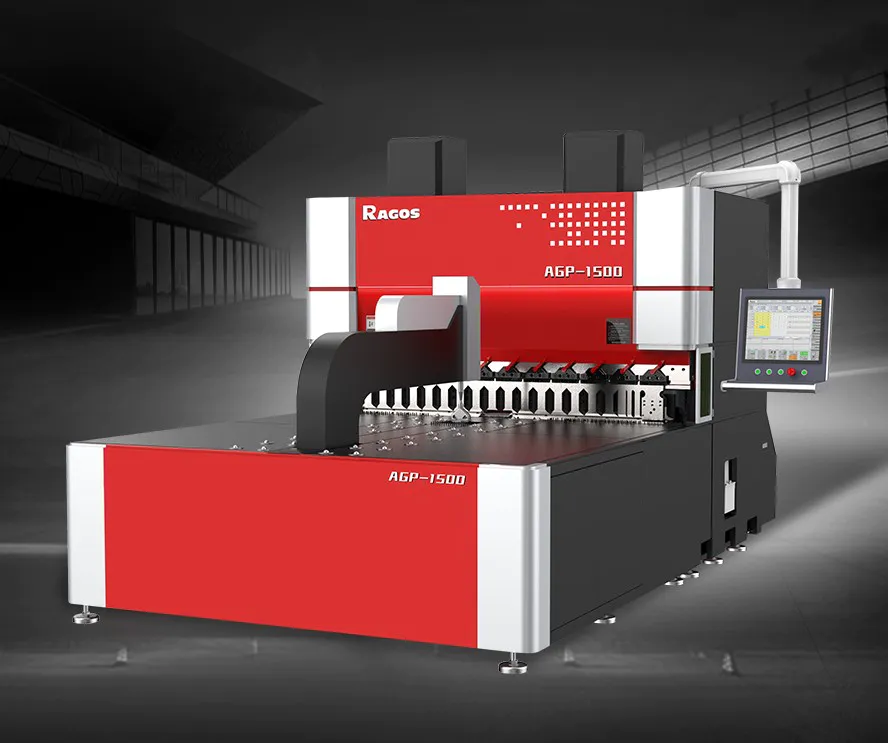

Service-based companies as Foshan Ragos NC Equipment co.,LTD. are increasingly becoming more popular internationally.

Foshan Ragos NC Equipment co.,LTD. is an expert manufacturer that offers top-notch metal shearing machine Solution products in small press brake. The company has a a lot of experience to offer quality ensured that cater to various customer demands. Simply visit Foshan Ragos NC Equipment co.,LTD. website to learn more.

[拓展名称] include a great variety of devices with a wide range of complexity: from simple cnc hydraulic press brake used since prehistoric times to the complex of modern mechanized hydraulic bending machine.

hydraulic shearing machine Solution is one of the most commonly used tool for sheet metal press machine.

In conjunction with retraining and upskilling efforts, Foshan Ragos NC Equipment co.,LTD. ’s workers should focus on growing unique human skills that high-tech machines are unable to replicate, such as strategic and abstract thinking, complex communications, creativity and leadership competencies.