The technical field of torsion axis synchronous numerical control

bending machine, specifically relates to a torsion axis synchronization device of a bending machine. The torsion axis synchronization device includes a synchronous torsion axis, a swing arm connected to both ends of the synchronous torsion axis, and a swing arm connected to the swing arm One end of the swing arm is movably connected with the synchronous torsion shaft, the other end of the swing arm is movably connected with the connecting rod, and the bottom end of the connecting rod is provided with a swing arm pier, below the swing arm pier A slider reinforcing rib is provided, and the slider reinforcing rib is arranged on the inner side of the slider and supports the slider. The two ends of the synchronous torsion shaft can move synchronously, so that the two ends of the slider can move up and down synchronously to meet the requirements of balance. The torsion axis servo bending machine has the characteristics of reasonable design, simple assembly adjustment, simple parts processing, and improved product quality. The electro-hydraulic servo

CNC bending machine does not need to take special measures during the return (up) stroke. In the fast forward phase of the down stroke, on the basis of parallel synchronization, two one-way throttle valves are used to eliminate manufacturing quality, leakage, etc. The deviation caused by the factors guarantees the downlink with a certain synchronization accuracy. When entering the work advancement stage but has not yet contacted the workpiece, two correction plunger cylinders installed on the workbench are used for further synchronous correction. Imagine that one side first comes into contact with the correction plunger, and the larger correction force slows down or stops the movement of that side until the other side catches up and contacts the correction post hydraulic and pneumatic plugs at the same time. The correction force can be set by the overflow valve and read by the pressure gauge. Practice shows that the synchronization effect is very obvious, this is because various asynchrony factors can be ignored compared with the correction force. 1. Wuxi Sunerchi believes that the biggest difference is that the two sides of the bending slider have different structures to ensure synchronization. The torsion shaft is synchronized by connecting the two cylinder pistons at the same time, and the electro-hydraulic servo is synchronized by the servo synchronization valves on both sides. 2. The electro-hydraulic servo has high synchronization accuracy, real-time error feedback, and strong anti-deflection load capacity of the bending slider; the torsion axis synchronous bending machine has low synchronization accuracy, no error feedback, and poor anti-deflection load capacity of the bending slider. 3. The hydraulic control system of the electro-hydraulic servo bending machine is more complicated than that of the torsion axis synchronous bending machine, and the price of the whole machine is also high. One is to adjust the stroke of the cylinder mechanically, and the other is to control the stroke by hydraulic pressure. The torsion shaft is synchronized by the balance shaft, and the electro-hydraulic servo is synchronized by the servo synchronization valves on both sides. The price of CNC bending machine is determined according to the customer's purchase demand, and is carried out according to the actual situation of the factory.

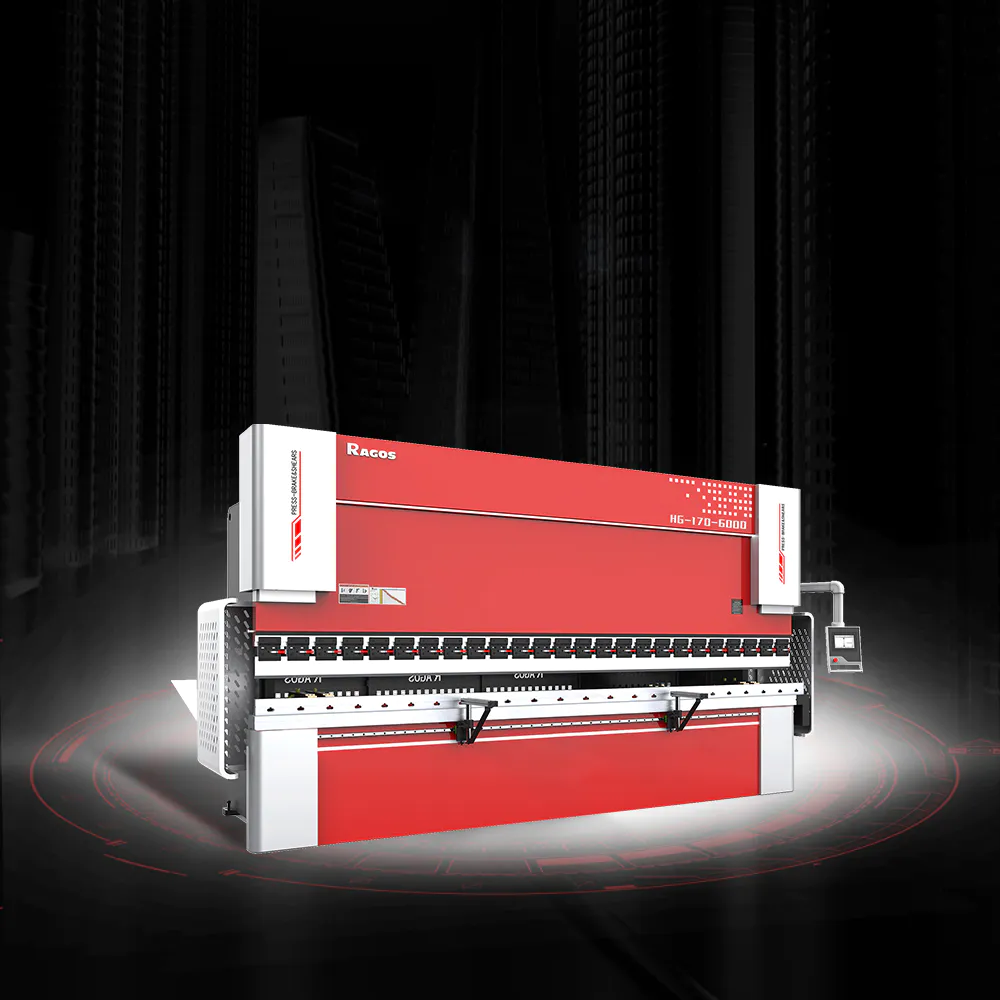

Foshan Ragos NC Equipment co.,LTD. helps high-profile clients build strategic relationships that drive company growth, investments, funding and more. There are many make-or-break details involved in the day-to-day manufacturing within our company.

Finding the best products has been made easier, at Foshan Ragos NC Equipment co.,LTD. . Here you can see completed ranges of produced with advanced equipment and strict quality control. Go to Ragos

Press Brake Machine and send your enquiry if you have any question.

Did I make the right decision? Am I saving money? Would I do it this way again? Yes, yes and yes if you choose to visit Ragos Press Brake Machine and make your enquiry.