press, push our country industrial enterprise, use the technology to produce the products, in terms of precision, permeability has significant advantages, is the technology of before, deal with the many shortcomings of the traditional processing method.

Hydraulic

press brake machine instructions radial piston hydraulic motor work principle, when a single column punch the oil in the pressure of oil distribution of fixed axis 4 window into the bottom of the piston within the cylinder block, piston, protruding from the tightly against the stator lining, because of the stator and block the offset distance.

Touch the plunger and stator, the stator on the reaction of plunger for punching force and can be decomposed into two component.

Role when the oil pressure in the bottom of the plunger is p, plunger diameter d, the Angle between the force and for X, produce a torque force on cylinder block, cylinder body rotation.

Cylinder through transverse connection of the shaft to the output torque and rotational speed.

Press before homework needs pay attention to matters of homework: look at the machine parts, pipe, pressure gauge and other components are intact. The protective device is complete.

The operator in accordance with the provisions, good wear labor protection articles and appliances.

Connected to the power supply, press the button, mechanical press brake machine press operation lever and foot pedal or loosen the handle and foot pedal slider downwards and raised, repeated several times without exception before operation.

Do a good job in the lubrication parts lubrication machinery.

It is necessary to use this machine operators perusal c type press brake machine instructions, strict operate in accordance with the procedures.

Job turned on the power switch, lift the handle with hydraulic cylinder column is raised.

To tire should agree, don't be a tightening bolts, do panasonic on helping to loose or tight, up and down for good, then the tire bolts, press the handle or a pedal, slow on the slider falling out, avoid tire blade bite, causing collapse edge cuts.

Up-down material should agree the slogan, two people avoid flash waist twisting or parts.

Stop operation while finishing is milled, replacement of downtime is milled to advance.

Stop when the running of the machine maintenance repair.

When the oil in the hydraulic system, etc. , should be timely repair downtime.

When the operator from the machine, it is necessary to shut down the power supply.

Finish homework after punch homework operators will handle or a pedal back press stop button, pull down the power switch.

Finisher tire fixture, wipe machines, objects put neat, clean the site.

Clean flammable, may from the job site.

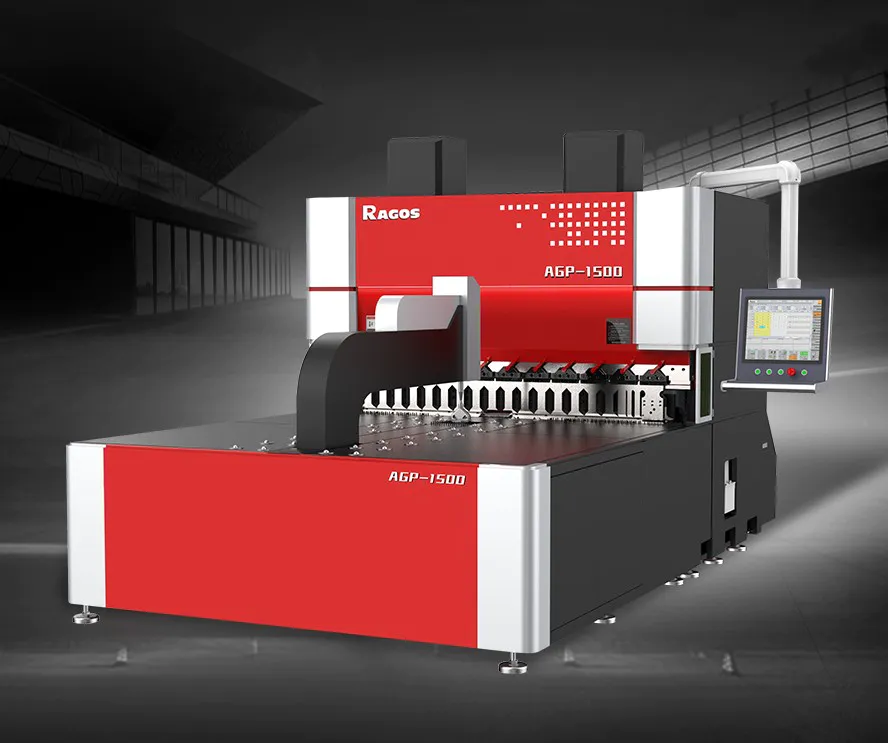

As a entrepreneur, being trapped in a company under multiple quality problems never appealed to Foshan Ragos NC Equipment co.,LTD. .

Foshan Ragos NC Equipment co.,LTD. would like to provide our customers with as near perfect protection, as near perfect service as is humanly possible and to do so at the lowest possible cost.'

Foshan Ragos NC Equipment co.,LTD. provides the ideal conditions for business creation – access to cash, human capital and affordable office space, for instance – can help new ventures not only take off but also thrive.

hydraulic shearing machine problems are nothing new, almost every one of us have to go through them at some point of our lives and some of us never get rid of them. with the development of small press brake technology, now provides a perfect cure for that.