Ragos Support customization of non-standard equipment:like press brake machine, CNC bending machine, metal bending machine. precision the world Style press brake tooling, Special configuration profiles are available in a variety of fitting styles and quality grades to suit virtually any forming need.

To be the world's most reliable sheet metal forming equipment manufacturers!The main products are press brake machine,cnc bending machine,metal bending machine.

RAGOS produces the widest variety of hydraulic press brakes available today. From our HG 5 axis cnc hydraulic press brake series we offer more than 20 models and ranges from a small press brake that start at 0.6 foot in length to large press brakes up to 16 foot in bending length and more than 10 different tonnages ranging from 35 to 200 tons. Our premium more advanced ADS series is available with up to 14 CNC axis, Our HG series machines are top end precision and powerful metal benders offered in 13 different tonnages with capacities In addition to these two popular press brake series, we also offer the MG series for the customer that needs a no frill press brake. On the other side of the coin is the sophisticated AD Servo brakes that have a hybrid hydraulic configuration and ball screws for energy efficiency and quiet operation. Lastly, RAGOS brings to market the HG series which equates to the “flexible bending solutions” press brakes. Our brakes are typically high tonnage press brakes made to order to customer exact specifications with the option of running tandem or even trio press brakes, and material automation and handling options of every description.

| Parts name | Parameter | Unit | |

| Nominal pressure | 1600 | KN | |

| Workbench length | 4000 | mm | |

| Distance between columns | 3500 | mm | |

| Slider stroke | 250 | mm | |

| Open height | 500 | mm | |

| Throat depth | 400 | mm | |

| Axis number of NC | Y1、Y2、X、R、V | axes | |

| Main motor power | 15 | kw | |

| Speed of slide | Fast down | 160 | mm/s |

| Work | 10 | mm/s | |

| Return | 130 | mm/s | |

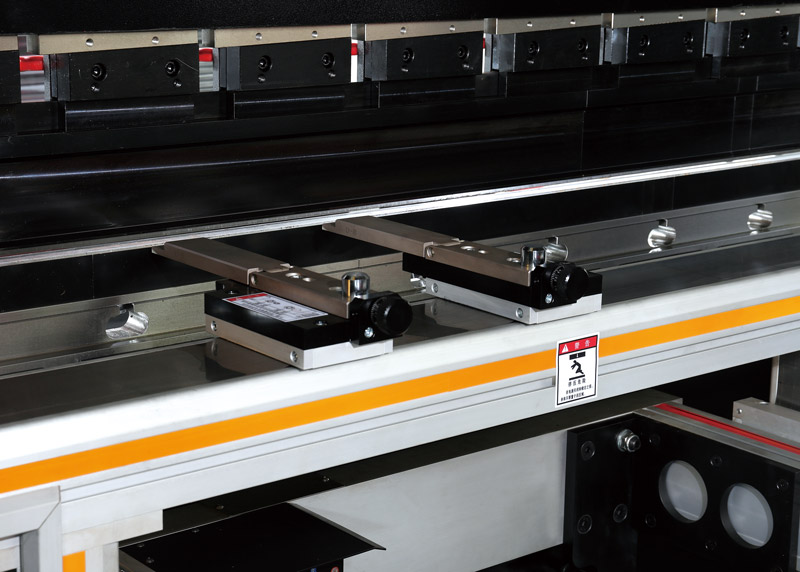

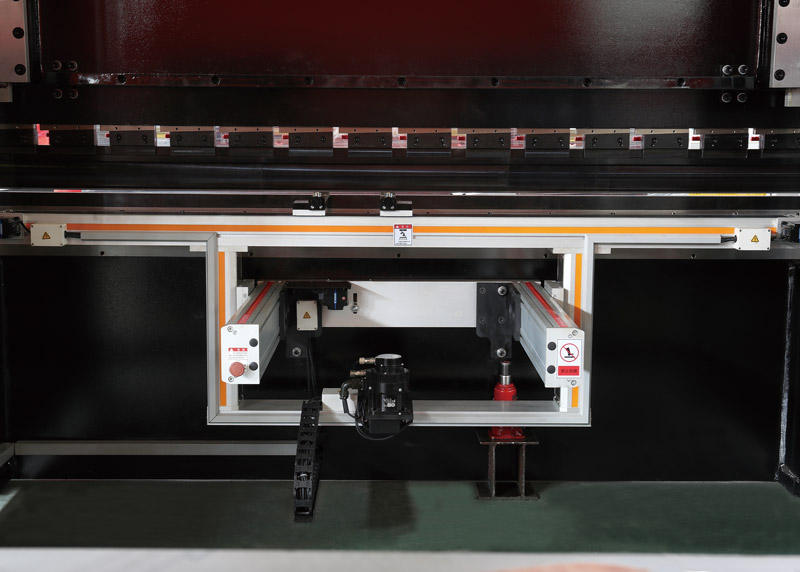

| Back gauge X-axis | Stroke | 600 | mm |

| Max. speed | 350 | mm/s | |

| Re-position accuracy | ≤0.05 | mm | |

| Back gauge R axis | Stroke | 200 | mm |

| Max. speed | 200 | mm/s | |

| Re-position accuracy | ≤0.05 | mm | |

| Machine Dimensions | Length | 4600 | mm |

| Width | 1900 | mm | |

| Height | 2900 | mm | |

| Machine weight | 12000 | Kg | |

| No. | Name | Country | Supplier |

| 1 | NC system | Italy | ESA S630 (optional) |

| Holland | DELEM DA-53 series (optional) | ||

| Switzerland | CYBELEC Cyb Touch12 PS (optional) | ||

| 2 | Servo motor | Japan | Yaskawa |

| 3 | Sealed linear encoder | German | ELGO |

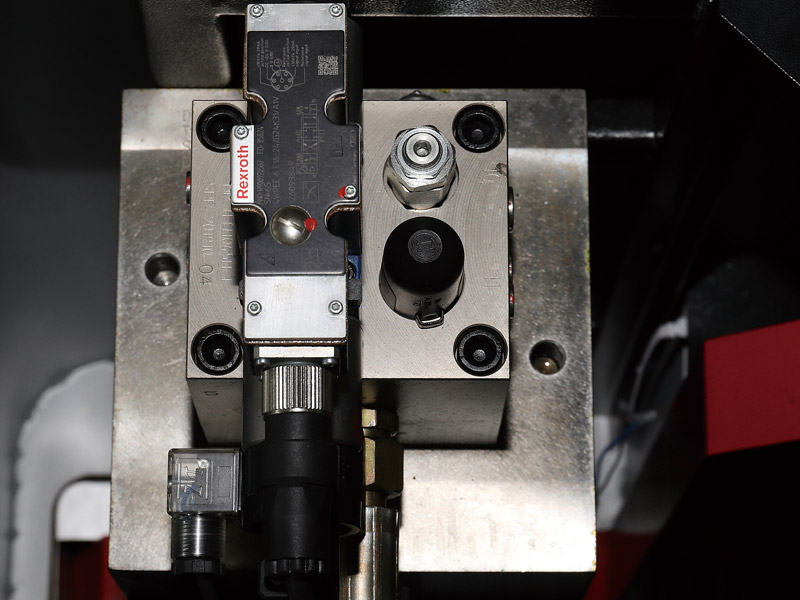

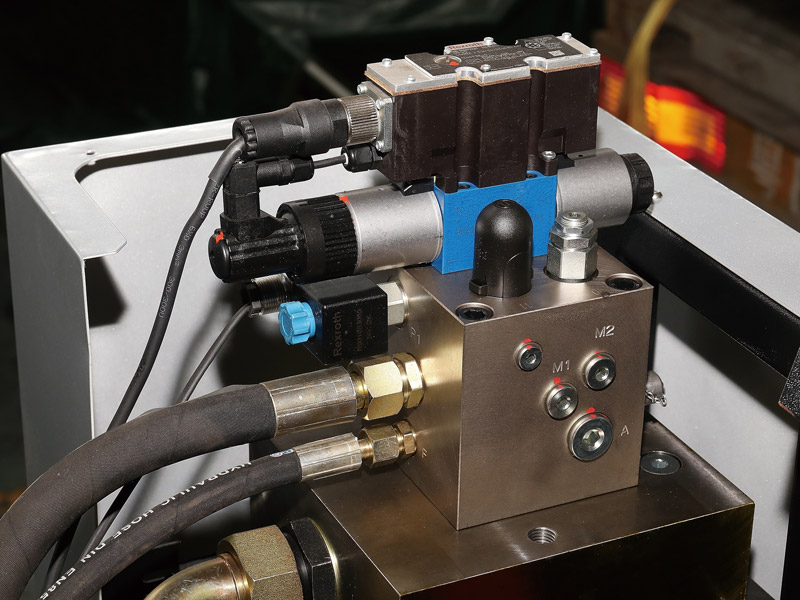

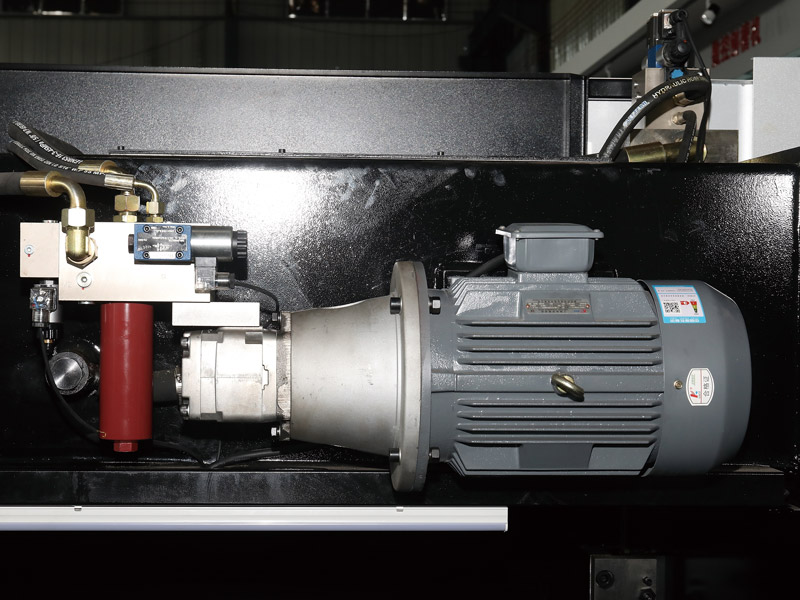

| 4 | Hydraulic system | German | REXROTH/HEROBIGER |

| 5 | Oil pump | German | VIOTH |

| 6 | Ball screw | Taiwan | HIWIN/PMI |

| 7 | Straight guide rail | Taiwan | Taiwan HIWIN/ PMI |

| 8 | Seal | USA / Japan | USA/Japan NOK |

| 9 | Air switch | France | Schneider |

| 10 | Miniature relay | France | Schneider |

| 11 | Ac contactor | France | Schneider |

| 12 | Button | France | Schneider |

| 13 | Electrical components | France | Schneider |

| 14 | Socket joint | German | German original |

111

Copyright © 2025 Foshan Ragos NC Equipment co.,LTD. (panel bender) | All Rights Reserved

We are here to help you! If you close the chatbox, you will automatically receive a response from us via e-mail. Please be sure to leave your contact details so that we can better assist you.