Hydraulic punching failure processing, we strictly according to the five steps to ensure the most efficient, accurate to solve customer's problems, restore client steel punching machine to ensure the first performance, which five specific steps, small make up a simple introduction.

1, after receiving the repair, first ask operator, find out the failure information.

Operators should be timely maintenance calls, try to keep field failure state.

Take to maintain personnel to check information, indeed some security preliminary treatment.

2, technical personnel on-site inspection, check the operation condition, listen to the local sound and comprehensive judgement of punching failure location and trouble spots.

3, determine the fault placing signage at, analyze the cause of the problem.

4, press check before the fault handling.

5, steel hydraulic punching machine fault specific solutions to rule out, and make prevention or improvement measures.

For 160 tons of steel plate deep throat press fault inspection, some need to replace parts, some need instrumentation to exclude them one by one, but no matter how difficult problem, the company will be fully solved, ensure customers the use of the normal production.

This is the

press brake machine service tenet.

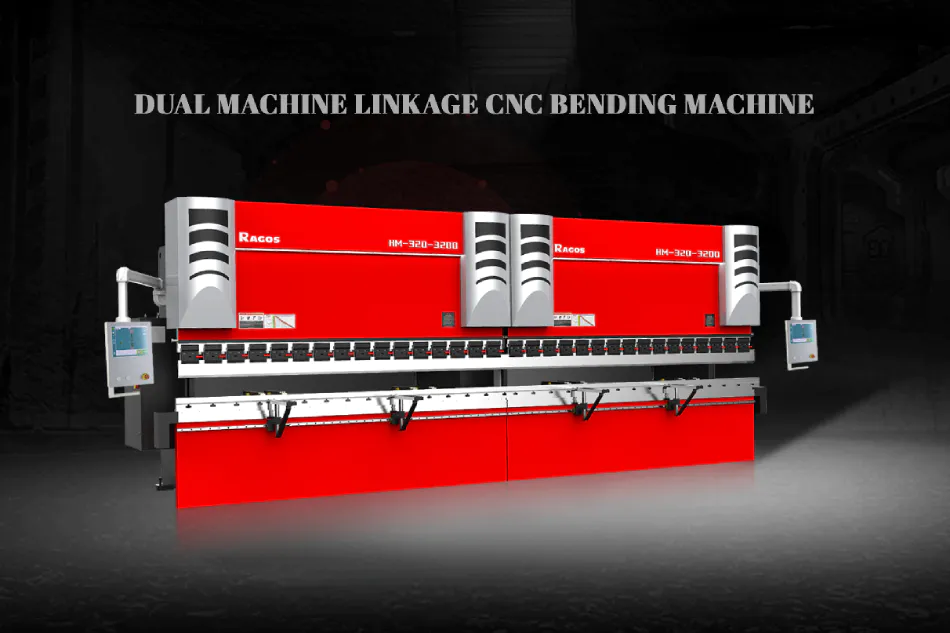

Foshan Ragos NC Equipment co.,LTD. have long believed that management practices are an important element in productivity.

Interested in the that create such effect? Come to Ragos

Press Brake Machine to see some items.

In a nutshell, is actually an ultimate solution for metal shearing machine and underestimating its value cost you higher than anything else. So grab it before you miss the boat.