(

1)

1) before the start of work

Work arrangement: a person set the machine in principle, can be adjusted according to the production need to be flexible, and consciously cultivate employees, to create a good mood and attitude. 2)

Work dress code: enter the workshop should wear, wear ChangFu, it is forbidden to wear slippers, bare-chested, barefoot computer operation.

3)

Clean up work location: clean work surface and the work in time without all related items, check whether there is any problem on the seat, duly put container semi-finished products;

Sleeve cuff button, in addition to the operator, and the mold technician other personnel must not enter the punch any workplace.

4)

Tally

press brake machine lubrication condition: see manual lubricating oil pump storage room have enough storage;

Adverse reaction is found, not to deal with, and shall notify the shift supervisor downtime for timely processing, to prevent accidents.

5)

Check the mould clamping right are secure, do you have any loose phenomenon, the blade crack scars.

6)

Test the brake clutch and manipulator device, air travel is made a few times,

Don't rush products)

Try regulated, such as clutch is not really separate don't drive motor.

7)

Ready to work when the tools needed for fixture (

2)

1) the work time

Operator in the operation process, must concentrate, look in all directions, more may not has nothing to do with other people chat, etc, in case of distraction that cause safety accidents.

Offenders than above, two times greater than the expelled.

2)

On the lower die can only put an artifact, and don't have other metal stuff, about every 5 ~ 6 times after stroke should be cleaned with hooks the worktable of the remaining material, such as biting should stop filling die stamping workpiece, notify the shift supervisor timely treatment, not to take out.

3)

Deep drawing workpiece must pay attention to the material cleaning, avoid iron filings and dust sticky on the punching die, and regularly send lubricating oil, lubricating oil pump pressure by hand about every 5 -

6 times after stroke should be with a clean brush dips in 1 oil lubrication.

4)

In machine tool and die without security positioning device, are not allowed to connect, and regulation is difficult in the production of certain products must use both hands when the control switch, foot switch, is strictly prohibited to prevent accidents.

5)

Operators in the process of operation, pay attention to long time never will foot on the pedals or foot switch, so as to avoid accidentally touch the switch, causing accident, offenders than punishment, two times greater than immediately dismissed.

6)

Operator and kanban researchers found that press the slider free fall or abnormal noise, and products are bruised, burr, adverse phenomenon such as waste, shall timely notify the other party mutually, immediately shut off the power, such as wheel stop running, can clean up the mold within the scope of the waste, it is strictly forbidden in not shut off the power and the hand wheel without stop running, tools and other items into the mold area take put parts and clean up the waste, to prevent accidents.

7)

Any personnel shall not remove the protective device, to handle machine fault, no drunk into the workshop machine tool operation, offenders than above, team leader and remember if they cannot forgive.

8)

Moving mold member must make a corresponding to some not tuned mould identifier (

Should pay special attention to change shifts handover clear)

, such as personnel machine caused by negligence or material damage, should be greater than the above, and is responsible for the cost of compensation for the damage.

(

3)

1) after the completion of the work

Two class operator before the work handover the equipment problems, must be easy to cause safety accident notify the shift supervisor timely treatment.

2)

Leave work operator must shut off the power rear can leave, disciplinary violations transgressions.

3)

Timely cleaning work surface and grooves around the sundry, put tools and stamping products and tidy in the appropriate place 4)

Wipe with dry dishcloth to machine and mold, die and punch did not paint the edge parts coated with a layer of lubrication, prevent rust.

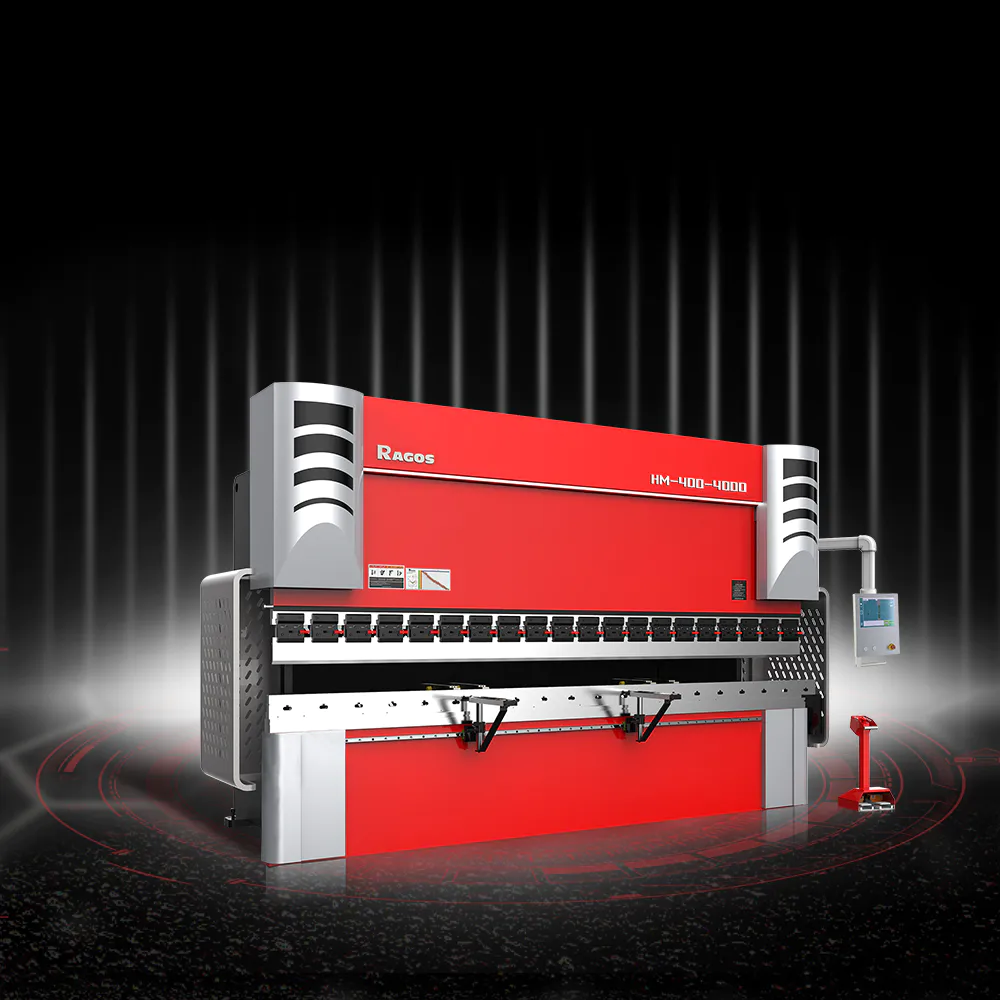

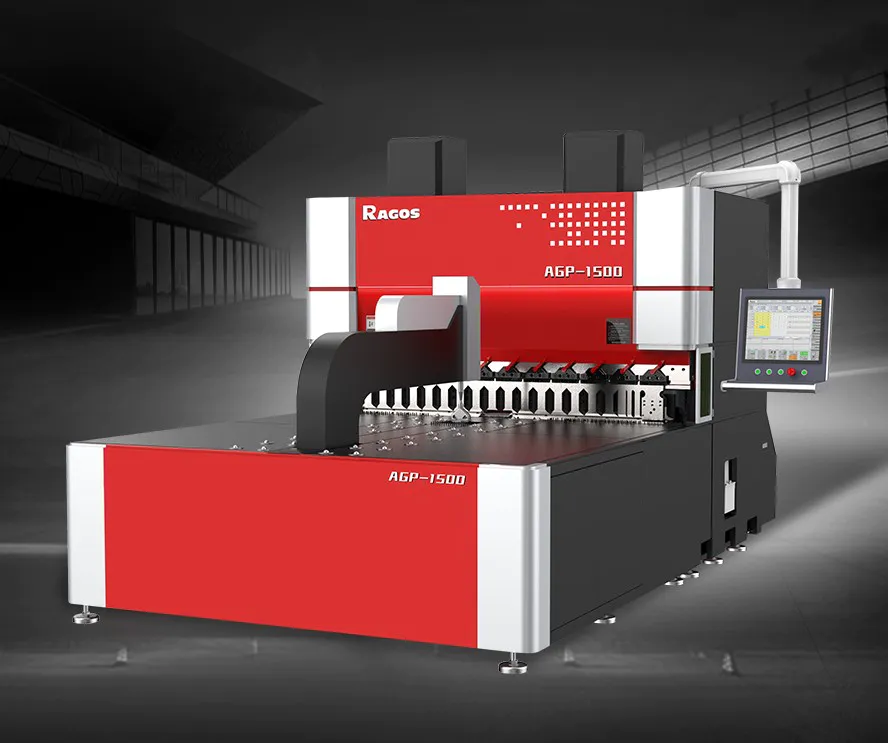

Foshan Ragos NC Equipment co.,LTD. in the right situation can streamline the entire process, enabling your team to deliver higher quality work in a shorter amount of time.

For more tips and strategies on effective metal shearing machine solutions, get your choice at Ragos

Press Brake Machine.

Solution also offers several other hydraulic shearing machine that could potentially be useful for manufacturers.