Hydraulic press is more and more recognized by customers and trust, 100 tons of hydraulic press is one of the tonnage model.

The use of some problems may happen in the processing, this analysis follows, requirements of customers can have certain help in used: 1, hydraulic punch processing appear broken reasons: material surface is sundry; knife with sundry; turn the knife dish tower belt material with sundry tools.

Magnetic.

Program is not reasonable.

Cutting tool clearance;

Cutter interference;

Processing methods: material surface is clean up the sundry, with air gun and cloth.

Check the cutting tool and mould for scrap iron debris, clean up with cloth, tape in the tool surface.

Choose according to plate thickness under the appropriate die clearance, ground and in use for a long time to demagnetization of tools and composite cutter square hole, cutting tool, choose the most suitable close didn't feedback biotech assessment open special tools or LASER cut.

With special shape both close apart, to consider first blunt that a knife, a cutting tool are too far apart to some interference.

2, 100 tons of hydraulic press appear scratches phenomenon reason: incoming bad there are wounds; personnel is expected to put up and down there are wounds; mould drawing injury;

To wrap around the front cut processing methods: incoming bad injury refused, the lacquer that bake.

Drawing, but must know the location of the lacquer that bake, injury severity, and decide whether to adopt.

Loading, two people must be vertical lift at the same time, vertical drop, for CRS material, must put the ball lay.

File burrs are not allowed to be piled artifacts together, workpiece are not allowed to drag on the board, put the smooth.

Neat, each layer number is consistent, must not be more than a metre in height.

Knife dish brush short, thick plate with hard brush, special molding tool under high, want to brush up, try to put the tools in a far away from the other tools or add M01, adopts the installation method in program production, program optimization, reduce the workpiece in the mold above drag.

3, hydraulic presses appear deformation phenomenon reason: mold die too short;

Too close to the mold apart of interference;

Too close to

press brake machine die cutting position and grip;

Deformation process (

Mesh, special molding)

;

Methods: lower die mounts.

Compete die cutter as far as possible away from other mould installation, can't put two lower die high together, two special molding are far apart will have interference, want to consider at first a knife and avoid a mold.

Secondary processing as far as possible with inner ring A work station, cutting position and the clamping jaw position to keep A certain distance, grip height shoulds not be too high or low, to flush with the brush.

Coining mesh porous knife or use to trump the processing, the coining from outer to inner processing, interlaced processing.

The whole plate blanking two processing, processing grip side first, and then turn the material 180 & deg;

Machining the rest; change order trimming mesh again first.

Special molding coining has deformation, it is possible that pressure, replace the spring extensions, lower die cutter.

Above three points is about 100 tons of hydraulic press processing production of some of the problems, and meet this kind of failure is the most reasonable solution, used in punch, user needs attention in order to avoid some unnecessary production safety.

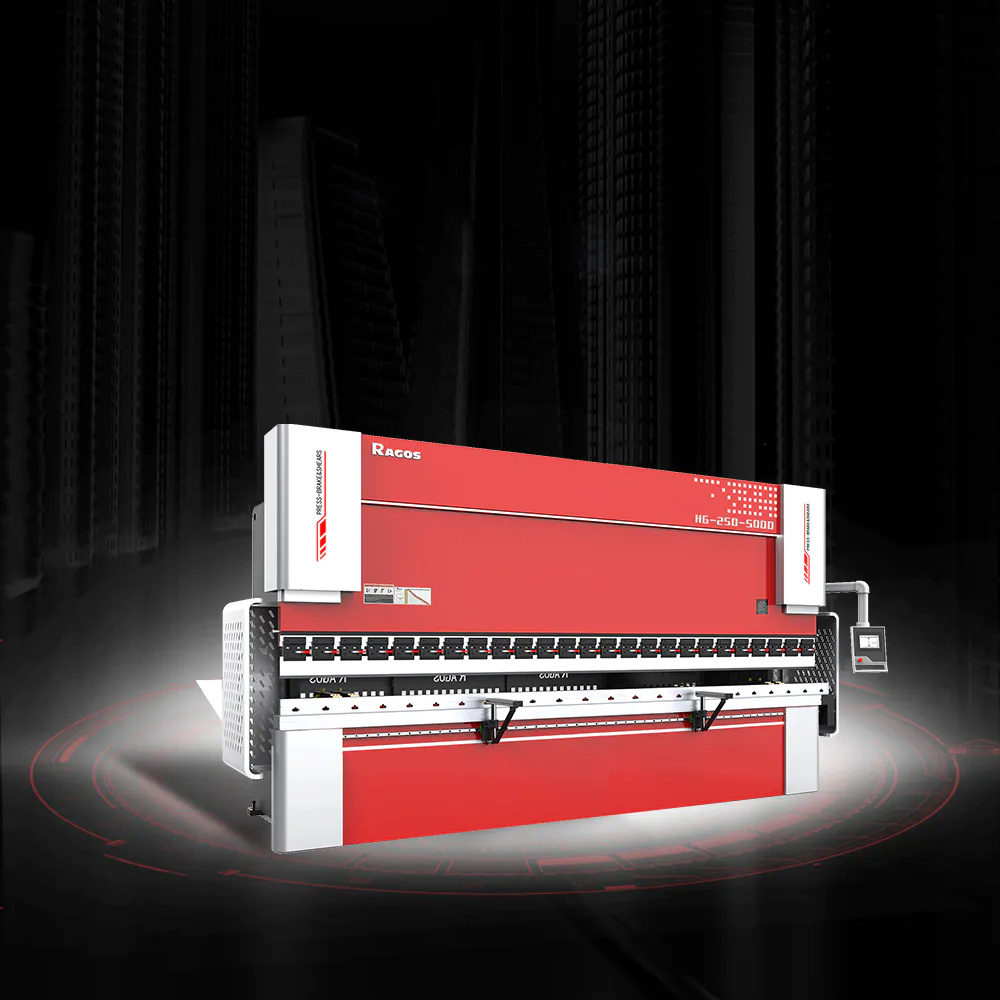

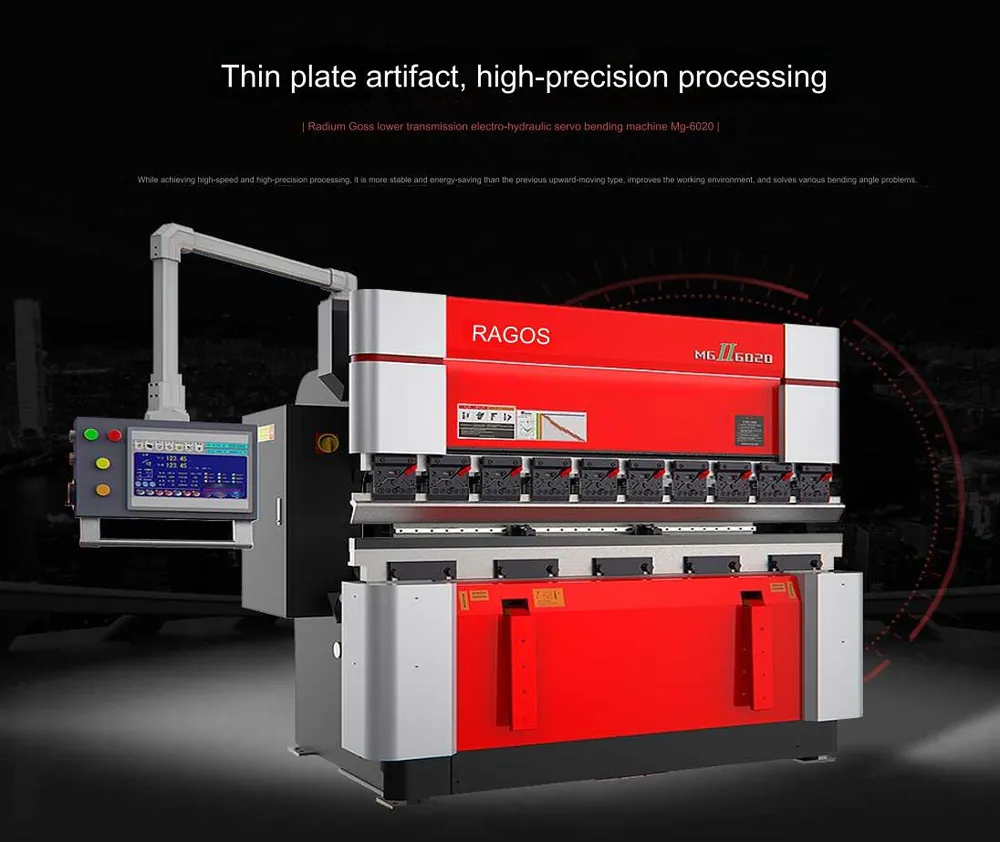

Foshan Ragos NC Equipment co.,LTD. continued to crave a more intense, personalized workout experience.

Our mission is to operate the best specialty retail business in domestic, regardless of the product we sell. Because the product we sell is Solution, our aspirations must be consistent with the promise and the ideals of the volumes which line our manufacture.

In terms of Solution, why is it different than other production? How does it fit a true need or desire for your requires? Is it simple to use? Make life easier?

Foshan Ragos NC Equipment co.,LTD. agreed, noting that successful social marketing will become an even more important component of overall marketing strategies, and that marketers will have to think longer, harder and more creatively if they want to be able to fulfill the newly created potential of sheet metal equipment.