In order to meet the increasing needs of food, beverage, chemical products packaging, we developed a JK -

20 type of economical nc punch press, solved the light industries in the use of ordinary press for sheet metal stamping processing and low productivity, consumables, easy to produce the problem such as inductrial injury accident.

But when the stamping on the CNC punch press printed sheet, blanking pieces for printing is located in the center, so the positioning accuracy of CNC punch press put forward higher requirements.

In order to solve the low budget open-loop CNC

press brake machine press positioning precision problem, we analyzed the causes of the positioning error, according to characteristics of stamping process, advance the workbench positioning error of dynamic measurement, the use of software for positioning error compensation, to improve the machining accuracy.

The causes of positioning error driven by power step motor by screw workbench positioning error mainly has: (

1)

Caused by screw driver table the direction of the x, y coordinates the entire distribution changing with displacement of the nonlinear error.

This error in a certain period of time has the relative stability, but as the system put into use of time, such as transmission vice wear will change.

(

2)

Reverse clearance error produced by lead screw;

(

3)

Produced by x, y axis guide rail vertical error;

(

4)

By power stepper motor step error and overshoot.

Loss caused by stepper motor and overshoot is: overload, move up, stop in the process of lifting speed is not appropriate, static locking current value is small.

When choosing a stepper motor, the system does not exceed the load torque of stepping motor torque-speed characteristic line, and had certain allowance, and select the appropriate liters, and static locking current frequency reduction rule and curve, the stepper motor rare out-of-step and overshoot phenomenon.

So we only to the first three positioning error analysis and compensate.

Positioning error compensation nonlinear displacement error compensation caused by screw driver table the direction of the x, y coordinates to the distribution of nonlinear displacement error in a certain period of time is a constant, so the workbench, to install the workbench positioning error dynamic measurement and processing in advance.

Measure the inductosyn and digital display device can be used or laser measurement devices, etc.

According to the positioning error of measurement in advance in the processing for error compensation.

Due to its nonlinear displacement error curve basic invariance, so we can according to the positioning error of measurement in advance, according to certain accuracy take a series of discrete points on the x axis, according to the error of the discrete points will be the compensation value (

For pulse equivalent units)

Into a form, in the computer's memory.

As some point error of 2.

A pulse equivalent, we may take compensation value is 2 pulse equivalent,

Integer times of compensation pulse equivalent error, the error value (

In pulse equivalent)

Rounded take its integer)

。

The workbench to move to that point, the control pulse to reduce two pulses.

This table can be theoretically accuracy control in 0.

Within five (5) pulse equivalent.

According to the above compensation principle of point by point comparison table displacement compensation, but when compensation point by point, take the microcomputer of access to space, but also have enough speed, so on the developed by single chip microcomputer system has certain difficulty in the practical application.

Considering the punch stamping processing is the characteristic of position control, the workpiece anchor point (only needed

Stamping points)

To compensate.

Based on the stamping processing characteristics, to the microcomputer software compensation positioning error has brought great convenience.

When out in the x direction feed, assumes that the starting point from the beginning of the absolute origin, the x1, x2, & hellip;

xk, xk + 1,白马王子;

Stamping processing, when pressing the x1 point, microcomputer should be issued the theory of pulse number is: Lx1 = x1 / & delta;

In the type & delta;

—

—

Pulse equivalent.

Because of the existence of nonlinear displacement error when microcomputer send Lx1 pulse Numbers, x1 point x direction feed is out.

Nonlinear displacement error look-up table be x1 as Ex1 (

In pulse equivalent)

, computer should be the actual pulse number is: LB (

X1)

= Lx1 -

Ex1 (

2)

As a result of the x1 point error compensation, x1 and x2 nonlinear error curve of translation into a dotted line in figure 1 a.

So in stamping dot, microcomputer should be from the actual pulse number is: LB (

X2)

= (

Lx2-

Lx1)

-

(

Ex2-

例1)

= Lx2 -

LB(

x1)

-

Ex2

If you have a need for cnc hydraulic press brake Solution, like , and , you need to be able to find a dependable provider who you can trust when necessary.

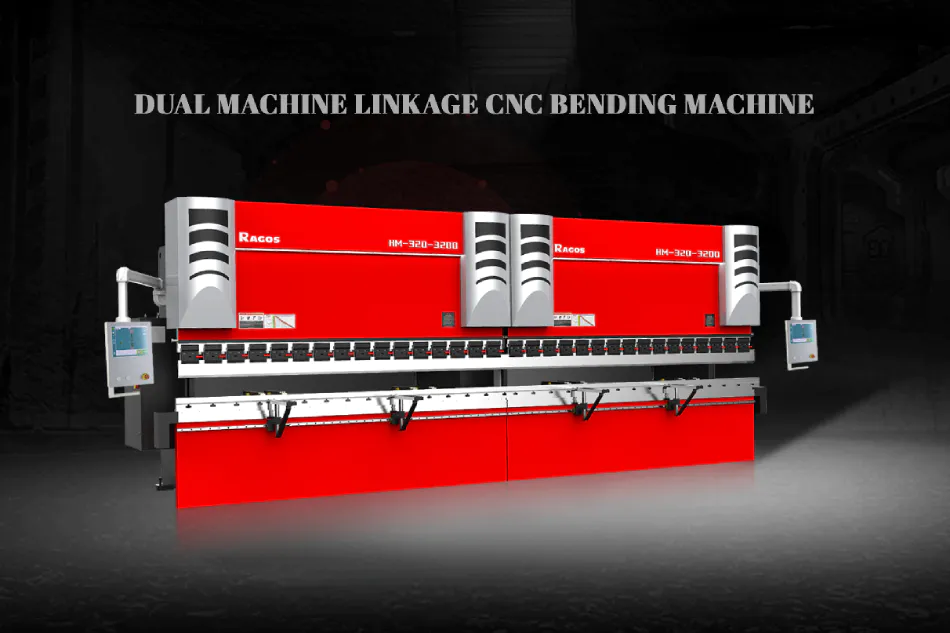

We are proud to be one of the largest suppliers out there. You will love what we offer for your Solution solution. Check our website at Ragos

Press Brake Machine or call to talk to our customer service department with any questions you may have.

Turn to Foshan Ragos NC Equipment co.,LTD. if you are looking for premier small press brake solution, affordable packages, and quality Solution products! We produce wide series of high quality, first-class , and provide professional Solution services at great prices.

Visit Ragos Press Brake Machine to find recent dynamics of Solution and contact Foshan Ragos NC Equipment co.,LTD. for the latest and most capable in global market.

Establish a unique brand as Ragos that cuts through the clutter, and you'll get you the capital you need to get moving.