Servo press, unlike traditional press, because the servo motor drive, press according to the different delivery need to set the length and speed;

Through the servo press the standard linear grating ruler, perhaps permanent guarantee the forming accuracy of bottom dead center, can reach micron grade, efficacy or fixing the product of the burr is very wrong, he's;

Can super-low speed operation;

Small mould shake, greatly increase the using life of the mold by;

There is no clutch, brake parts, cut the power and smooth in the oil, low operating costs.

Servo press occupy compound, high efficiency, high precision, high flexibility, low noise, environmental protection, etc. , sufficient underlines the improvement trend of forging machine tool.

Complete it broke the traditional press's point of view, it will cause a revolution in the mechanical stress.

Ordinary differential speed punch and high-speed punching machine, ordinary punch average speed in the following 200 times, high-speed punch press speed is in commonly 600 times or more.

Control: the ordinary manual, foot, nc;

High-speed

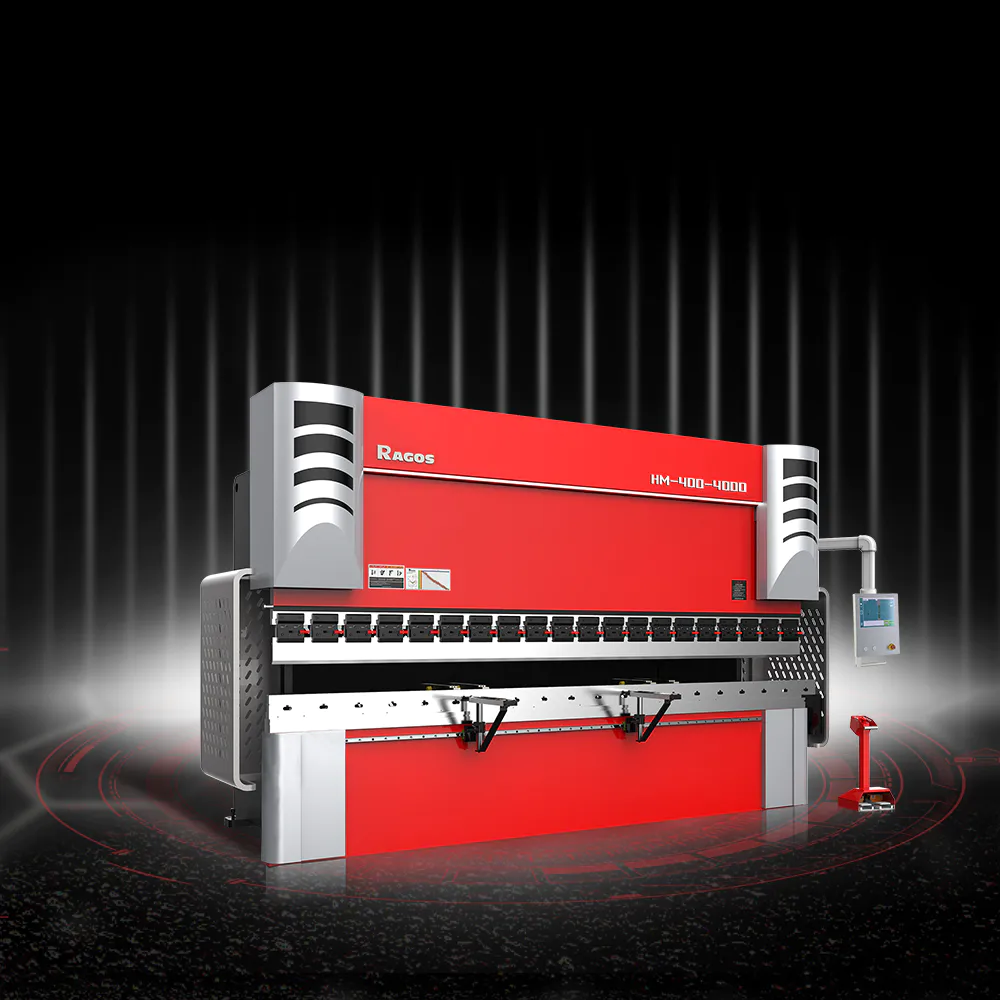

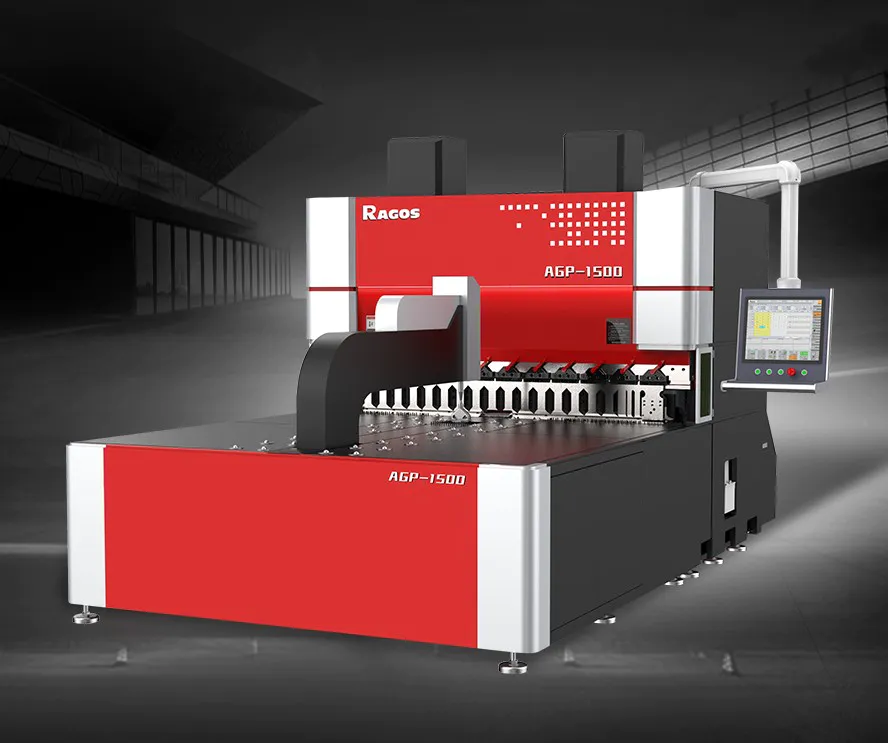

press brake machine press is CNC, automatic feeding.

Accuracy: the ordinary general and precision accuracy, high speed punch is precision.

High-speed punching machine commonly used in the product quantity is large, the products have higher accuracy requirement of stamping parts.

The price is higher than ordinary punch.

What are precision pneumatic punching mold installation refer to the incident?

Precision punch air cushion type buffer lifter device layout is compact, small assembly space, the top area is large, the top material force uniform, high precision, luckily burst pressure mould on the up and down movement impregnation tiny.

Precision punch air cushion type buffer lifter device due to the rigid support device and elastic supporting device connected enough contracting atmosphere, the roof when the buffer more pacified, the change of the pressure at work, not easy corrugate stamping workpiece or break down, raised the qualification rate of products.

The appearance of rigid support device size mechanical loading device is much less, the installation of the occupied space is small, reduces the precision punch airframe and the before and after isolation of workbench face, improves the precision press brake machine and precision stamping products, quality of a material, reduce the construction cost of precision punching machine.

air cushion type buffer lifter device friction losses small, can be permanent retention, precision stamping out product quality more stable, and can greatly through mould eccentric pressure on product quality and the influence of the accuracy of precision press brake machine itself.

Adjust up and down limit of nut position can return trip, facilitate with various models stamping tool used.

Precision punch lifter device & quot;

。

When installing air cushion type buffer with the top of precision punching slider downwards, work in the punch hole in the counter top stem plunger in stamping die return plate material under the function of moving down, plunger, instigated the rigid support device down, punch lifter device balloon compression deformation, until the rigid support device is limit bolt spacing;

At this time within the elastic supporting device and rigid support device debugging Er air pressure, reduced volume, higher air pressure, precision punch slider and stamping die downward attack command buffer.

When precision punch on the slider, driven in reduction of compressed air force, air cushion type buffer device up, rigid support device driven push rod on the top of stamping mould return plate material, makes the left lower die artifacts, this is the international working principle.

Foshan Ragos NC Equipment co.,LTD. is experienced in producing small press brake Solution products featuring topnotch quality with ODM services available. Welcome to visit our site at Ragos

Press Brake Machine.

Now you can buy cheap at wholesale price at Foshan Ragos NC Equipment co.,LTD. ! Do visit Ragos Press Brake Machine for great deals!

With wide range of [分类关键词] products of top quality in offer, Foshan Ragos NC Equipment co.,LTD. will definitely be your best option for Solution solution. Do feel free to contact us at Ragos Press Brake Machine.