An overview, automatic

press brake machine feeder is appeared in the domestic market in recent years, the product with common press brake machine, ordinary punch was converted into CNC punch press, make the whole machine can realize the entire coin computer, automatic discharging, automatic feed, automatic stamping, and other functions, can maximize the use of raw materials, improve the efficiency of production, and processing all kinds of complex graphics, at the same time also has a manual machine operation, to ensure safety, improve working conditions and other advantages, is widely used in mechanical, electrical, instrumentation, cans, screen mesh, bottle caps, electric control cabinet, metal industries such as stamping processing.

Second, the technology introduction coin material after fixed by pneumatic or mechanical way, set up a zero position, after feeding system according to the punching hole shape automatically send the coin material to press brake machine punch punching below position.

After rushed a hole, the punch automatic lift, put the coin material feeding system needed for the next punch to punch below the punching position.

Such reciprocating rushed to send, until finish all rushed back to the zero position as required.

Concrete process is: coin material placed in the fixed frame of the automatic feeder, by air, and then based on the size of the coin material with the required products, the corresponding data input to the feeding system operating interface parameter dialog bar, the operator input values, system can fill the data according to the automatic operation, save and complex process of artificial calculation and programming, realizing automation production.

Can also according to customer's requirements to run the single point move.

Three, equipment of six axis numerical control system and PLC man-machine interface with a set of: for the punch press feed system control center, complete control over the linkage of the feed servo axis positioning movements;

Back to zero, manual and automatic operation;

Screen display and parameter setting;

Punching, positioning on the logic control of input and output signal.

NPN input/output board each piece: cooperate with numerical control system to deal with input and output signals, the main circuit protection.

Wade 1.

Inertia, 2, 5 kw.

0 kw of inertia in a set of servo motor on: two axis coin material fast accurate positioning, linkage for the quick response of servo motor and setting time has a higher request, wade servo adopts advanced control theory, performance fully meet customer requirements.

Four, debugging, punch press feed system of two servo axis feed speed and setting time has a higher request, the faster the speed, shorter setting time, as it ran straight pitch is allowed, the greater the punch of the higher efficiency.

So the servo actuator using coupling straight league, under the premise that the agency allowed, repeat the servo response time, quickly adjustable setting time is short.

Wade WD30 series servo controlled by robustness, in terms of response speed, setting time performance is remarkable, debugging used before the result is much higher than client.

Servo debug, fit the screw pitch and punch signal, debugging a security from the value of the largest continuous punching, CNC system input.

With top speed punching processing, detection pitch accuracy.

According to test results, adjust the machinery, the main is to adjust the installation of two axis perpendicularity and installation precision of the coupling, and the appropriate response bandwidth and lower servo nc system, deceleration time, make the precision and efficiency are achieved.

Five, summed up the CNC press brake machine press feeder fully combined the wade WD30 series of fast response, precise positioning, short setting time, smooth operation, etc.

Compared to the customer before scheme, not only have a great improve in punching precision and efficiency, and the Angle of circular hole, hole board, bore hole, arc and other laws can be automatically processed, maximize the customer satisfaction, not only improves the product yield and quality of customers, but also saves labor costs for our customers.

The equipment to the customer to fully demonstrate the technical ability of guangzhou wade electrical machinery co. , LTD. , at the same time, make the whole machine tools products on the market competitiveness greatly enhanced.

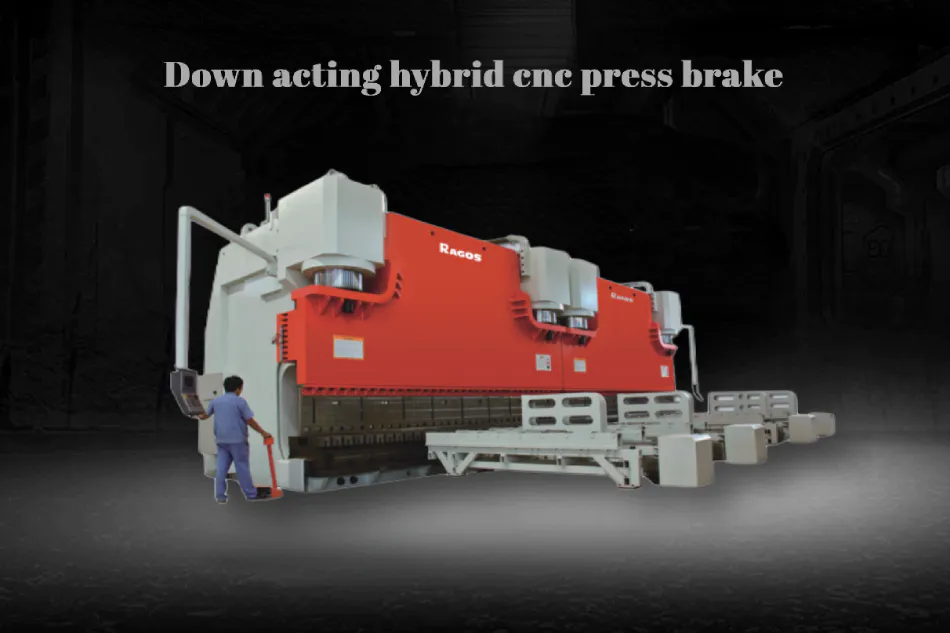

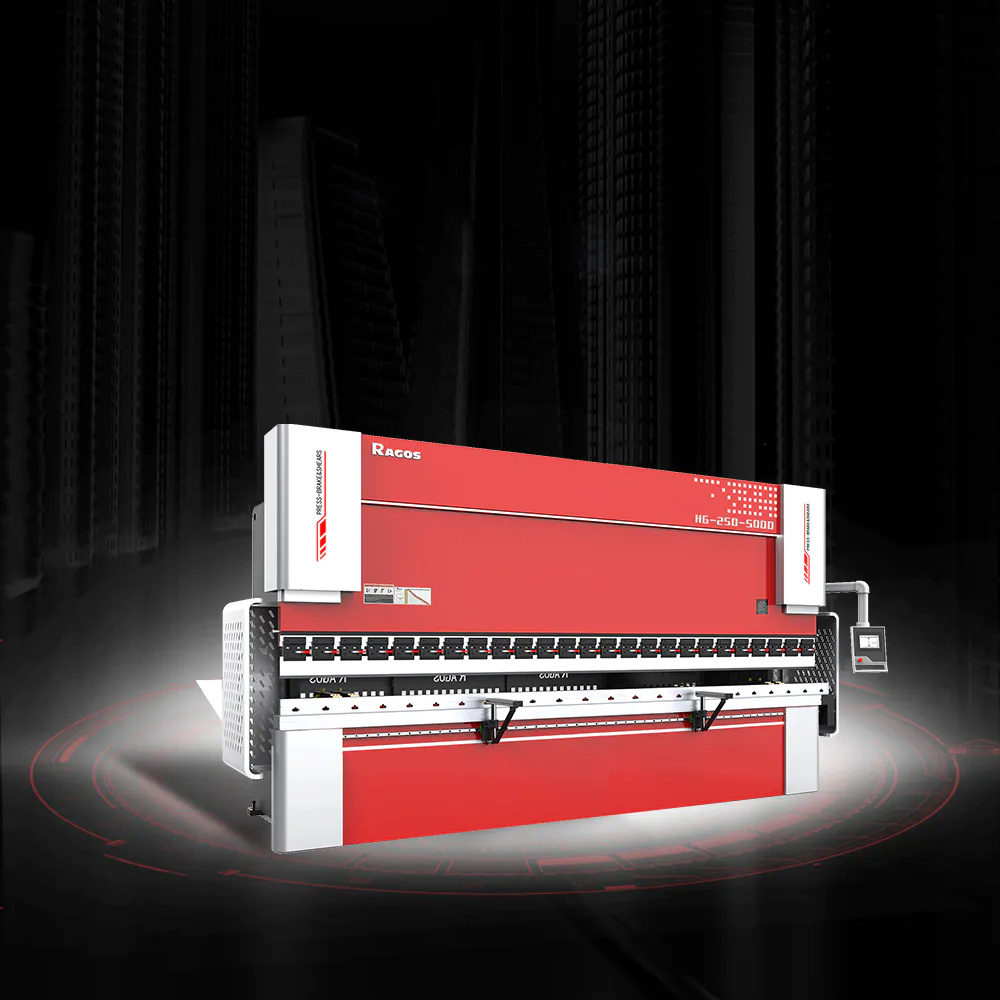

Foshan Ragos NC Equipment co.,LTD. , the best suppliers of domestic markets, has good faith in manufacturing.

With continuous operational improvements, expanding capacity and a strong competitive position for serving strategic domestic markets, Foshan Ragos NC Equipment co.,LTD. are positioned for long-term growth that will benefit our customers and investors.

A primary strategy is superior customer satisfaction. Foshan Ragos NC Equipment co.,LTD. constantly analyzes market needs around the world to develop a full range of products for different use.

The development of hydraulic bending machine Solution products has massive potential for expansion.

To offer abundant options of product is an important factor to a company, such as Solutionhydraulic shearing machine to afford high-quality products for customers.