Select several precondition for high quality

CNC bending machine 1, bending mold is made of high quality steel products made by special processing, has the high hardness, not easy to wear and tear, tolerance big advantages, but each mold has its limits under pressure: t/m, so when using the mould to correctly choose the length of the mold, that is, how much per meter to add pressure, must not be more than mould with the pressure.

2, in order not to damage the mould, we set on the origin, must use more than 300 mm in length on the origin of lower die, the origin of the good before you can use the same height of the upper die and lower die.

Split small modules is strictly prohibited to the origin, and the origin must according to the internal origin of the machine for the standard pressure.

3, when using the mould, due to the height of the various kinds of mold, and so on one machine can only be used when choosing mould also the height of the mould, can't use different height of the mould.

4, when using the mold, according to the material of sheet metal hardness, thickness, length, to choose the appropriate upper and lower die, generally used by the standard of 5 ~ 6 t lower die, the length is longer than the sheet, harder when the material, thickness of material, the greater the slot with wider application of lower die.

5, when bending acute Angle or pressure corner, should choose 30 degrees, fold acute Angle, after crushing, when bending R Angle, should choose die for die on R and R.

6, when bending long workpiece, it is best not to use segmented mold, reduce the knife indentation, and choose the best single slot, because of the single slot mold of V groove outside, R is large, is not easy to produce bending creasing.

7, when choosing upper die, specific which one to use on the mold, we should know about all the parameters of the mould, and then according to the shape of the product shape, you need to decide what kind of upper die.

8, in the hardware or sheet metal bending hardness, thickness of products, are not allowed to use a mold to bent steel or other cylindrical products.

9, when using the mold, should be clear, the machine after on the origin should lock the upper and lower die, don't let die down, hurt or injured mould, operating process, pressurized attention, do not add too much pressure, pay attention to the screen shows the data changes.

10, finished die back in time to die on the shelf, and according to the identification and often cleaning the dust on the mould, and coated with anti-rust oil, prevent rust, reduce the mould precision.

have manifold Solution effects, ranging from small press brake to hydraulic bending machine.

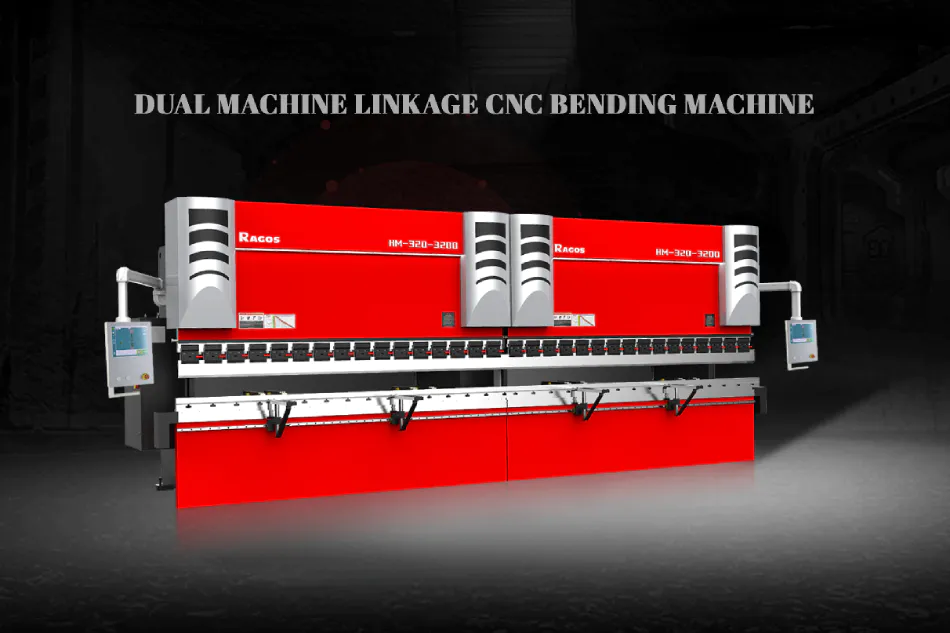

Foshan Ragos NC Equipment co.,LTD. will deliver superior returns to our shareholders by tirelessly pursuing new growth opportunities while continually improving our profitability, a socially responsible, ethical company that is watched and emulated as a model of success.

The development of hydraulic shearing machine Solution products has massive potential for expansion.

We want to be careful and deliberate about developing Ragos, from the platform we choose, to the way we approach it, to the methods we use.

Latest technology and manufacturing equipment has improved the quality of Solution.