Company Advantages1. Ragos has been strictly evaluated. The assessments include finite element stress analysis of all components, fatigue analysis, load increase analysis, etc.

2. The product has a translucent and smooth glaze surface which makes it stand out immediately. The clay used in it is fired at more than 2300 degrees Fahrenheit to help the white color show prominently.

3. The product stands out for its abrasion resistance. Its friction coefficient has been decreased by increasing the surface density of the product.

4. Foshan Ragos NC Equipment co.,LTD. is strict with the quality of our products.

5. Foshan Ragos NC Equipment co.,LTD. has a knowledgeable talent team and a stable and reliable production line.

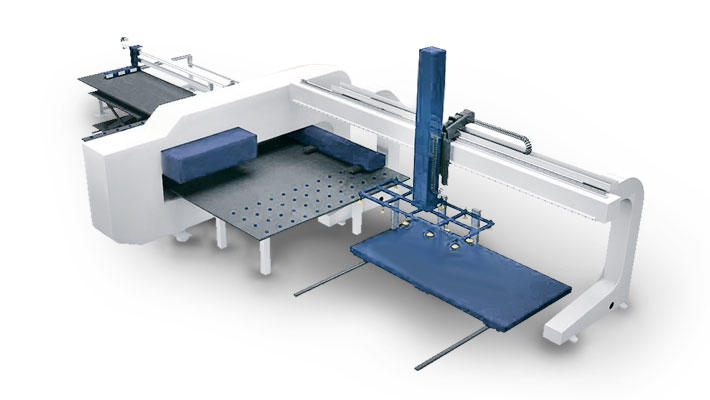

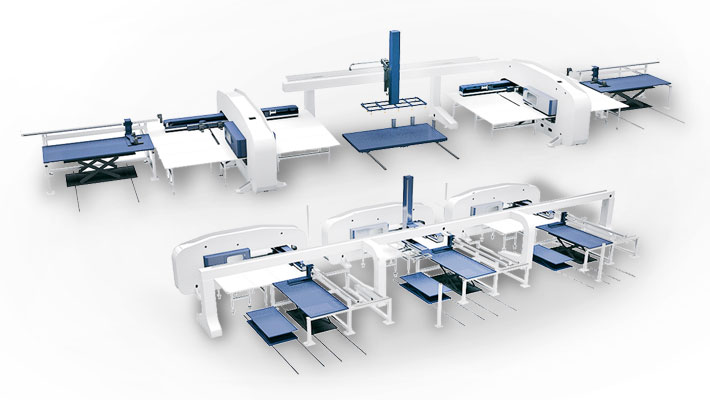

Machine 1

1. No one waits for feeding and discharging, and super-economical production of medium-sized to large-scale batches is completed.

2. Automated plate separation function and double-layer plate detection function;

3. The structure principle of feeding system is to use vacuum suction device as the tool of sheet metal robot to replace traditional manual feeding.

4. Improve work safety, reduce the risk of injury and reduce the intensity of staff.

5. The matching AGC cutting unit can be placed flexibly from left to right to meet the demand of production line and further improve cutting efficiency.

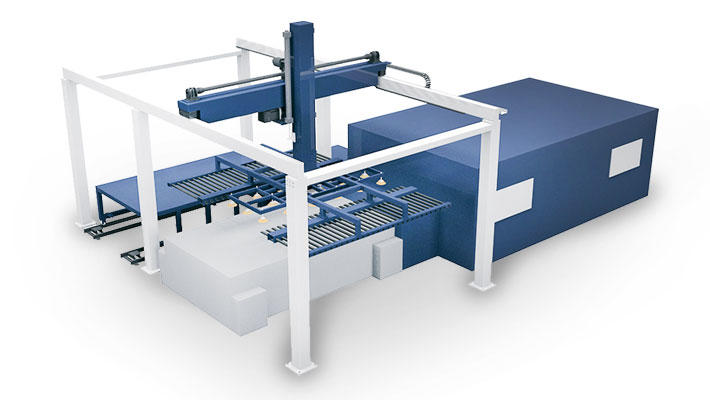

Machine 2

1. No one waits for feeding and discharging, and super-economical production of medium-sized to large-scale batches is completed.

2. Automation detection, plate separation function and double-layer plate detection function.

3. The structure principle of feeding system is to use vacuum suction device as the tool of sheet metal robot to replace traditional manual feeding.

4. Improve work safety, reduce the risk of injury and reduce the intensity of staff.

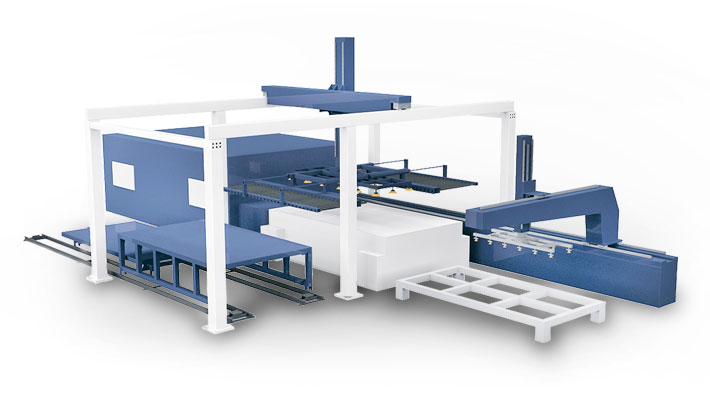

Machine 3

1. No one is waiting to finish the loading and unloading of the workpiece.

2. Plate separation function and double-layer plate detection function.

3. It is equipped with the off-line programming software developed. independently, which improves the operation convenience and efficiency.

4. Modular design makes it possible to match with the mainstream laser cutting machine in the market and customize it according to customers'needs.

5. Vacuum suckers are equipped with one-way globe valves to meet the requirements of different sizes of sheet materials.

Machine 4

1. No one is waiting to finish the loading and unloading and finishing of the workpiece.

2. Plate separation function and double-layer plate detection function.

3. Equipped with the off-line programming software independently developed by the company, which improves the operation convenience and efficiency.

4. Modular design makes it possible to match with the mainstream laser cutting machine in the market and customize it according to customers'needs.

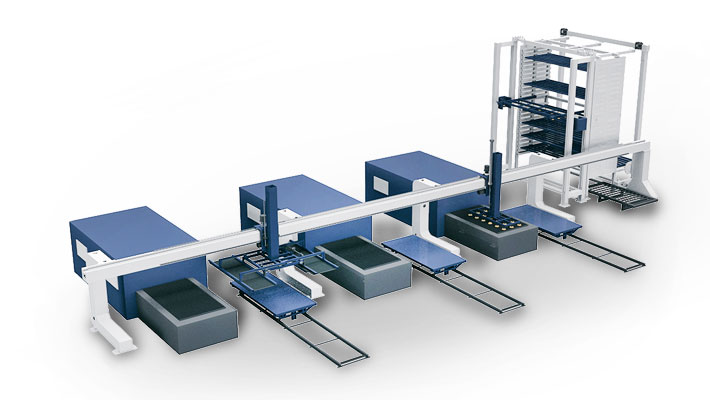

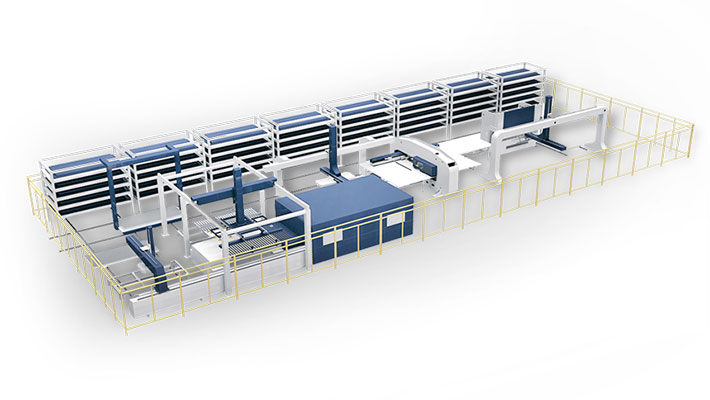

Machine 5

1. Automated unmanned work cycle, with the help of fast loading and unloading function, so that the machine tool has a higher utilization rate.

2. Matching the warehousing units of the whole upper and lower orders, the production rhythm is more optimized.

3. Extensible design, flexible configuration, realizing multiple laser links.

4. Modular design makes it possible to match with the mainstream laser cutting machine in the market and customize it according to customers'needs.

5. Realize multi-species and all-weather unmanned operation.

6. Equipped with roller positioning to reduce the time of edge finding for cutting plate.

Machine 6

外置拉链

1. Save the cost of start-up and equipment investment.

2. Plate separation function and double-layer plate detection function.

3. Compact connection with NC punch press makes space requirement lower.

4. A single NC punch with AGC cutting unit can be equipped with three-dimensional material storehouse to further improve production efficiency.

5. It can be customized according to customers'needs and has expanded ERP and MES systems.

Machine 7

手拉带

1. Save site, time and operation cost.

2. It can be matched with various sheet automation equipment units.

3. Enhance material flow speed to ensure orderly production.

4. Custom-tailored layer height, with expanded ERP, MES system.

Machine 8

车载/家用

1. Automation design is adopted, the machine occupies a small area, and the transportation cost is small.

2. Efficiency: Machines produce more in the same run time.

3. Because of the unmanned operation, the manual operation time is shorter and the machine operation time is longer.

4. With the same investment, stronger productivity, higher productivity, smaller footprint, fewer material storage and semi-finished products.

Foshan Ragos NC Equipment co.,LTD. has built a reputation over the years for providing high quality . We are becoming a famous manufacturer.

2. We have excellent manufacturing and innovation capabilities guaranteed by international advanced automated production line equipment.

3. Our company has adopted a socially responsible management approach. We only use production methods that are environmentally friendly. Check now! You’ll also like the simplicity of our pricing structure. We quote our prices the way we deliver them: FOB. You’ll only ever need to deal with GPP; we cover every aspect of shipping, storage, and delivery for you turnkey. Check now! While striving to provide the most satisfactory products and services, we will spare no effort to enhance our integrity, diversity, excellence, collaboration, and participation in corporate values. Check now! Our company bears social responsibilities. For instance, we are implementing waste management strategies to recycle sludge into dehydrated powdered sludge that can be used by cement companies to produce cementing mixtures.