Company Advantages1. Ragos sheet metal techniques is produced as per the industry specifications. The product features a high automation level, which helps reduce labor costs

2. The product has significant economic benefits and a good application prospect. The product is highly anti-interference to exterior elements

3. It is extensively acclaimed in the market owing to stylish patterns and designs. The product is able to process complicated parts

4. The product has excellent performance, stable and reliable quality. The product has advantages in thick or long plates

5. The product is durable, functional, and practical. With a robust structure, it does not vibrate during operation

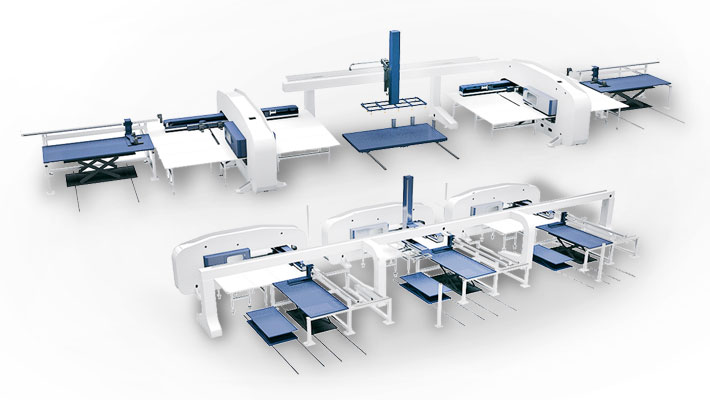

Machine 1

1. Automated work cycle, no need to wait for feeding and discharging, super-economical production of medium-sized to large-scale batches is completed.

2. Automated plate separation function and double-layer plate detection function;

3. The structure principle of the feeding system is to use a vacuum suction device as the tool of a sheet metal robot to replace traditional manual feeding.

4. Improve work safety, reduce the risk of injury, and reduce the intensity of staff.

5. The matching AGC cutting unit can be placed flexibly from left to right to meet the demand of the production line and further improve cutting efficiency.

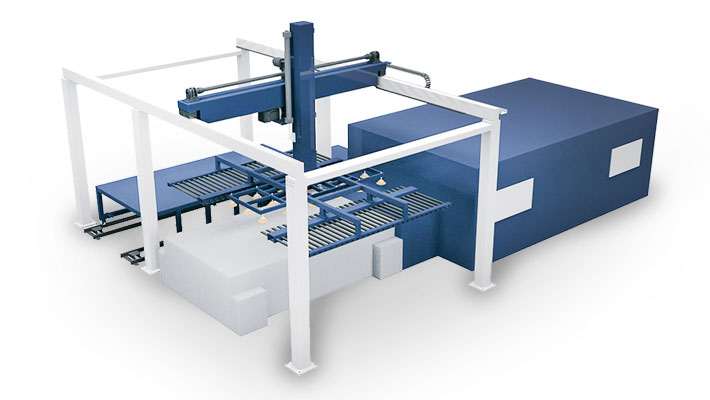

Machine 2

1. Automated work cycle, no need to wait for feeding and discharging, super-economical production of medium-sized to large-scale batches is completed.

2. Automation detection, plate separation function, and double-layer plate detection function.

3. The structure principle of the feeding system is to use a vacuum suction device as the tool of a sheet metal robot to replace traditional manual feeding.

4. Improve work safety, reduce the risk of injury, and reduce the intensity of staff.

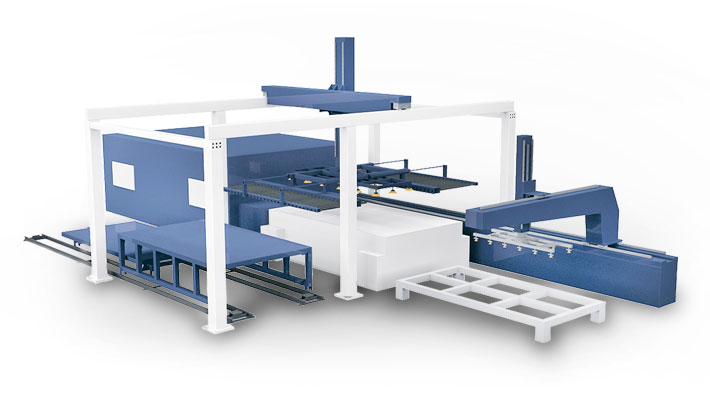

Machine 3

1. Automated loading and unloading of the workpiece.

2. Plate separation function and double-layer plate detection function.

3. It is equipped with the off-line programming software developed independently, which improves the operation convenience and efficiency.

4. Modular design makes it possible to match with the mainstream laser cutting machine in the market and customize it according to the customer's needs.

5. Vacuum suckers are equipped with one-way globe valves to meet the requirements of different sizes of sheet materials.

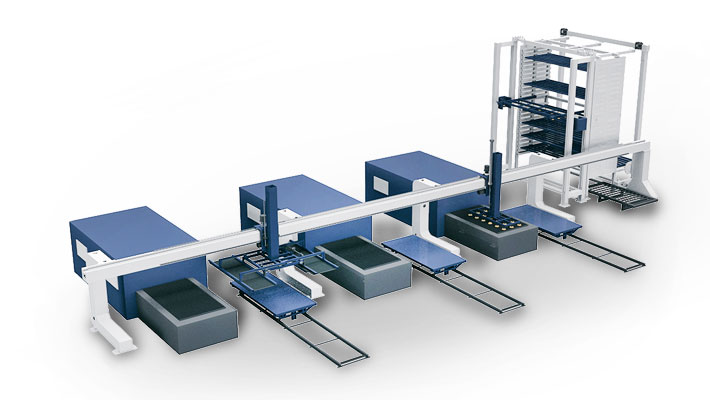

Machine 4

1. Automated work cycle, no need to wait for the loading and unloading and finishing of the workpiece.

2. Plate separation function and double-layer plate detection function.

3. Equipped with the off-line programming software independently developed by the company, which improves the operator's convenience and efficiency.

4. Modular design makes it possible to match with the mainstream laser cutting machine in the market and customize it according to customer needs.

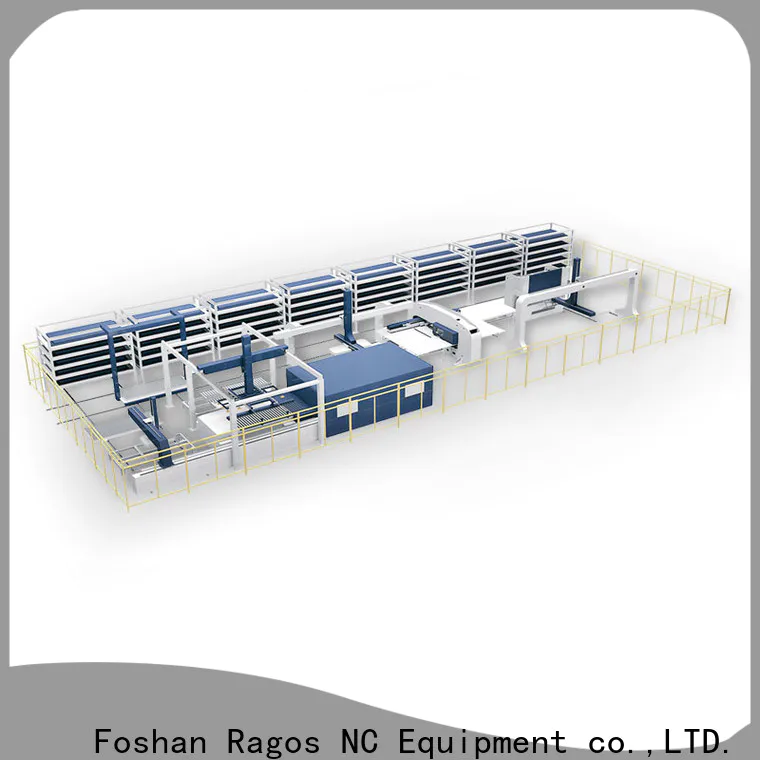

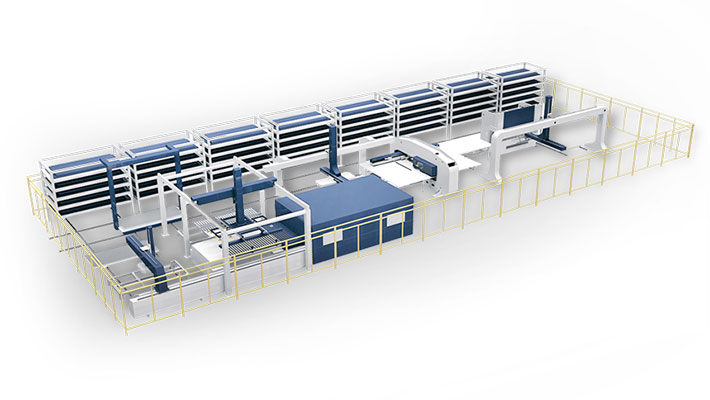

Machine 5

1. Automated work cycle, with the help of fast loading and unloading function, so that the machine tool has a higher utilization rate.

2. Matching the warehousing units of the whole upper and lower orders, the production rhythm is more optimized.

3. Extensible design, flexible configuration, realizing multiple laser links.

4. Modular design makes it possible to match with the mainstream laser cutting machine in the market and customize it according to customer needs.

5. Realize multi-species and all-weather unmanned operation.

6. Equipped with roller positioning to reduce the time of edge finding for cutting plate.

Machine 6

External zip

1. Save the cost of start-up and equipment investment.

2. Plate separation function and double-layer plate detection function.

3. Compact connection with NC punch press makes space requirement lower.

4. A single NC punch with an AGC cutting unit can be equipped with three-dimensional material storehouse to further improve production efficiency.

5. It can be customized according to customer needs and has expanded ERP and MES systems.

Machine 7

Hand strap

1. Save site, time, and operation cost.

2. It can be matched with various sheet automation equipment units.

3. Enhance material flow speed to ensure orderly production.

4. Custom-tailored layer height, with expanded ERP, MES system.

Machine 8

Car/home

1. Automation design is adopted, the machine occupies a small area, and the transportation cost is small.

2. Efficiency: Machines produce more in the same run time.

3. Because of the unmanned operation, the manual operation time is shorter and the machine operation time is longer.

4. With the same investment, stronger productivity, higher productivity, smaller footprint, less material storage, and semi-finished products.

We have quality-minded staff, including designers, developers, consultants, customer service workers, programmers, and producers. They are well-trained and have the ability and experience to provide solutions and services.

2. Ragos is a worldwide famous brand in exporting sheet metal techniques field. Check it!