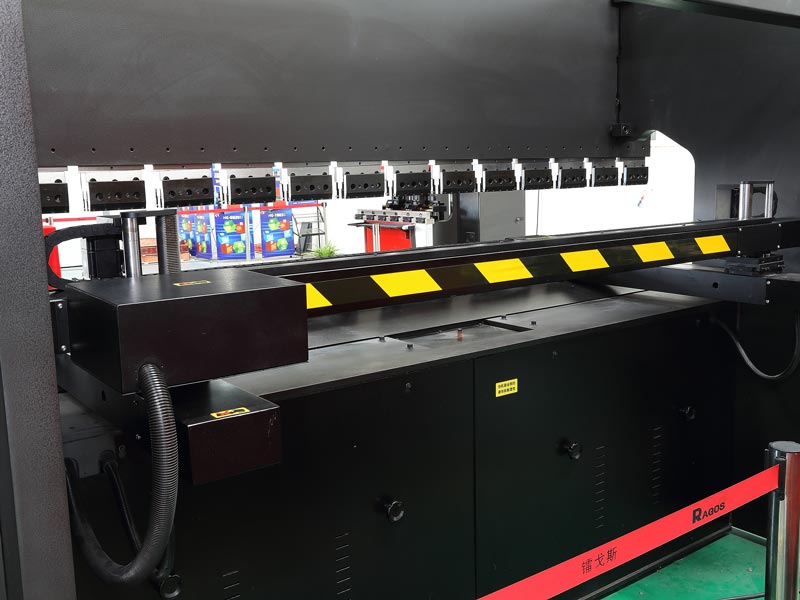

HG Series has the most advantage in thick or long plate. It brings best quality, simple operation and an attractive price-performance ratio. This means you can save the cost to make more profit within precise results as well as the highest safety standards.

| Parts name | MG-6020 | Unit | |

| Nominal pressure | 588 | KN | |

| Bending length | 2000 | mm | |

| Distance of side | 1700 | mm | |

| Throat depth | 405 | mm | |

| Machine weight | 4000 | Kg | |

| Opening height | 400 | mm | |

| Slider stroke | 100 | mm | |

| Work speed | Climbing | 52 | mm |

| Bending | 8 | mm | |

| Returening | 46 | mm | |

| Machine dimensions | Length | 2255 | mm |

| Width | 1440 | mm | |

| Height | 2070 | mm | |

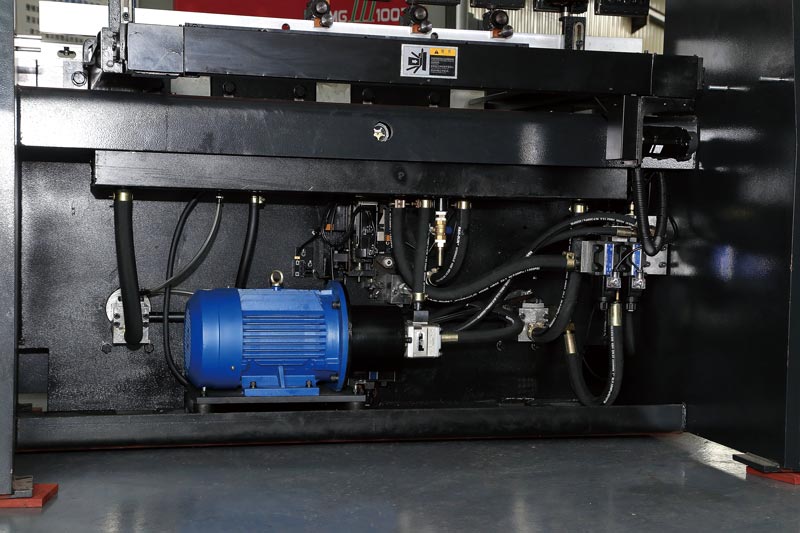

| Main motor power | 5.5 | kw | |

| Cylinders | 3 | pc | |

| Oil tank Capacity | 45 | L | |

| Name | Country | Manufacturer | Remarks |

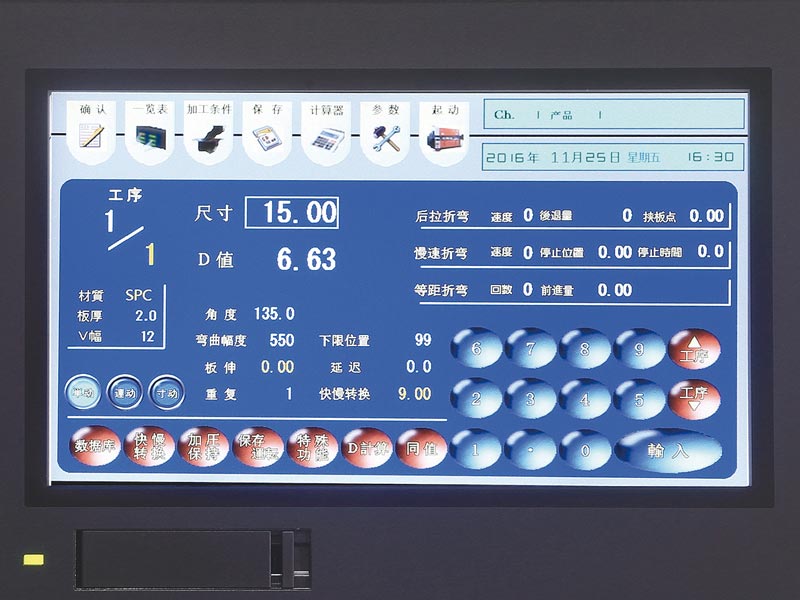

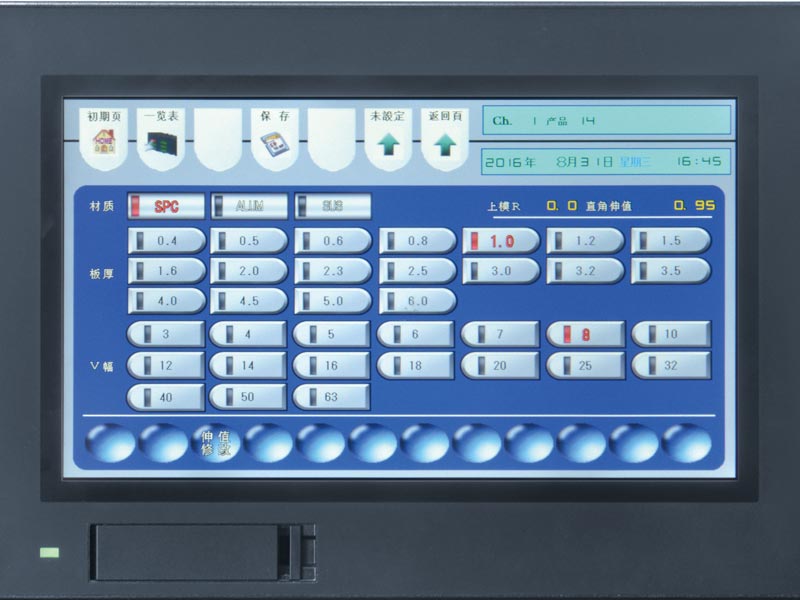

| Control system | Japan | Co-developed with Japan's NADIC |

|

| Servo motor | Japan | Japan Mitsubishi |

|

| Servo | Japan | Japan Mitsubishi |

|

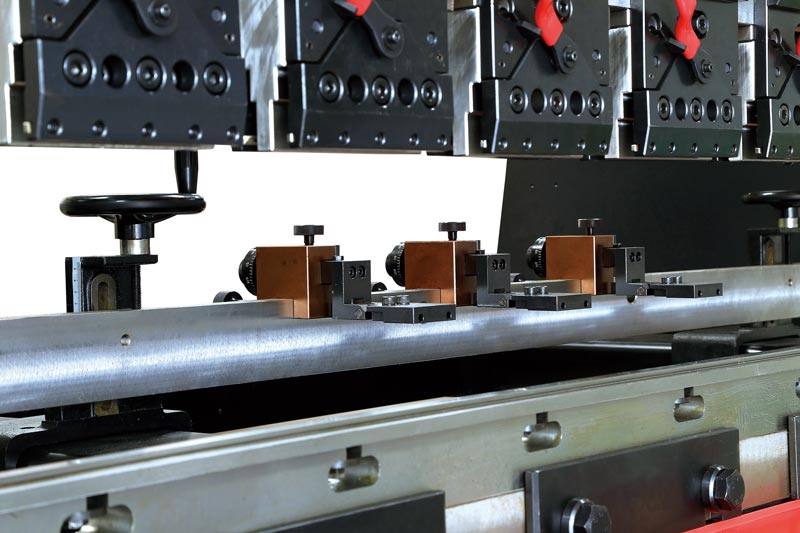

| Mold clamping | Japan | AMADAO riginal supplier double-sided clip |

|

| Oil pump | Japan / Germany | Japan Nachi/ German Eckerle |

|

| Oil valve | Japan | Japan YUKEN |

|

| Oil seal | Japan | Japan NOK |

|

| Cylinder | Japan | AMADA original supplier |

|

| Guide rail | Taiwan | Taiwan HIWIN |

|

| Ball screw | Taiwan | Taiwan TBI |

|

| PLC control | Japan | Japan Keyence/ Mitsubishi |

|

| Touch screen | China / Japan | Weinview / Japan Keyence |

|

| earing | Japan | Japan NSK |

|

111

111

Copyright © 2025 Foshan Ragos NC Equipment co.,LTD. (panel bender) | All Rights Reserved

We are here to help you! If you close the chatbox, you will automatically receive a response from us via e-mail. Please be sure to leave your contact details so that we can better assist you.