As one of the top ten bending machine factories in China, RAGOS provides the most advanced and reliable machines. 15 years of manufacturing and maintenance experience, exported to more than 30 countries. Inquire now! high quality. competitive price.HG Series has the most advantage in a thick or long plate. It brings the best quality, simple operation, and an attractive price-performance ratio. This means you can save the cost to make more profit within precise results as well as the highest safety standards.

| Parts name | Parameter | Unit | |

| Nominal pressure | 1250 | KN | |

| Workbench length | 3200 | mm | |

| Distance between columns | 2700 | mm | |

| Slider stroke | 250 | mm | |

| Open height | 500 | mm | |

| Throat depth | 400 | mm | |

| Axis number of NC | Y1、Y2、X、R、V | axes | |

| Main motor power | 11 | kw | |

| Speed of slide | Fast down | 160 | mm/s |

| Work | 10 | mm/s | |

| Return | 130 | mm/s | |

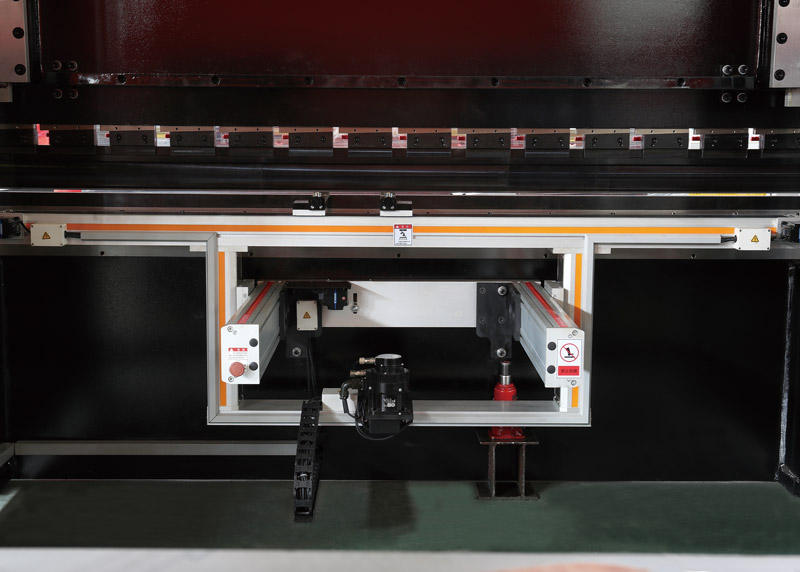

| Back gauge X-axis | Stroke | 600 | mm |

| Max. speed | 350 | mm/s | |

| Re-position accuracy | ≤0.05 | mm | |

| Back gauge R axis | Stroke | 200 | mm |

| Max. speed | 200 | mm/s | |

| Re-position accuracy | ≤0.05 | mm | |

| Machine Dimensions | Length | 3800 | mm |

| Width | 1850 | mm | |

| Height | 2750 | mm | |

| Machine weight | 9000 | Kg | |

| No. | Name | Country | Supplier |

| 1 | NC system | Italy | ESA S630 (optional) |

| Holland | DELEM DA-53 series (optional) | ||

| Switzerland | CYBELEC Cyb Touch12 PS (optional) | ||

| 2 | Servo motor | Japan | Yaskawa |

| 3 | Sealed linear encoder | German | ELGO |

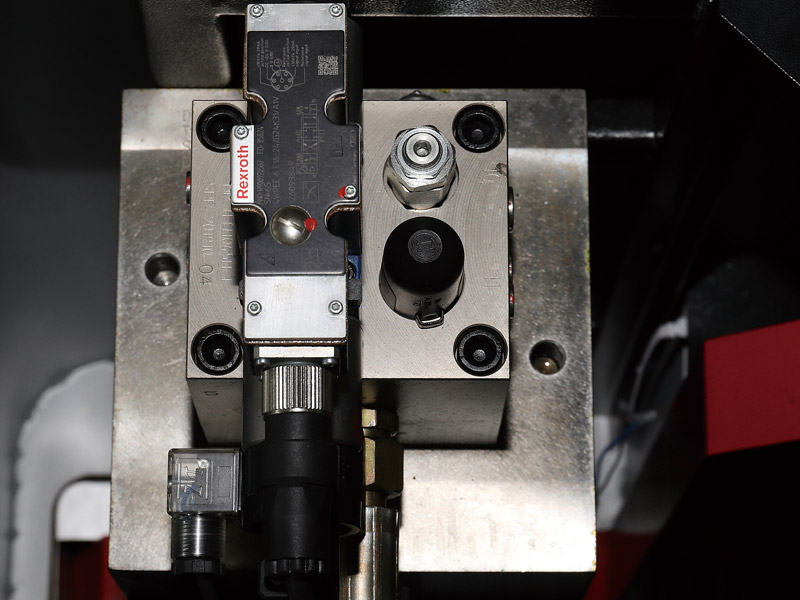

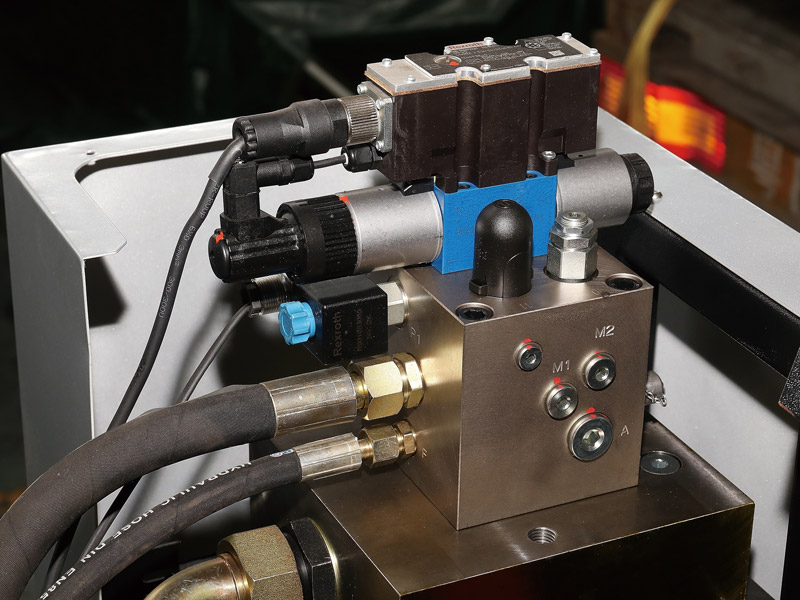

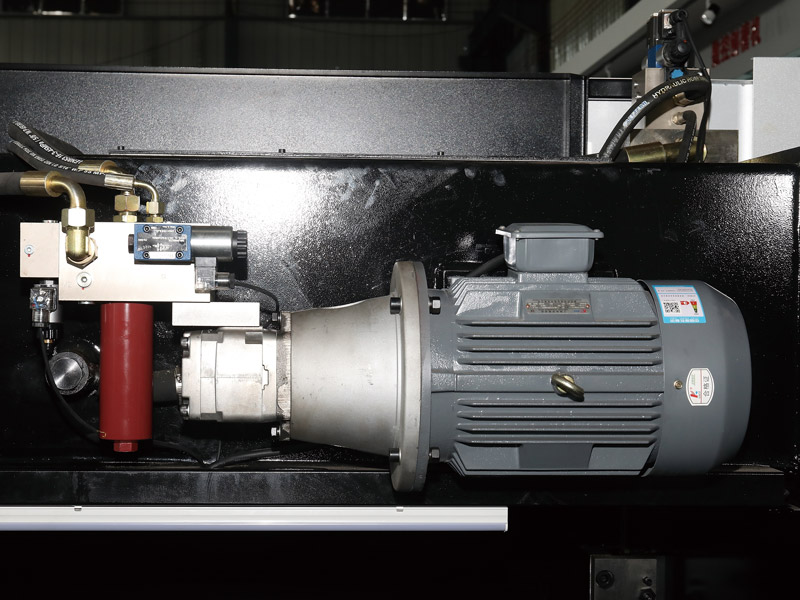

| 4 | Hydraulic system | German | REXROTH/HEROBIGER |

| 5 | Oil pump | German | VIOTH |

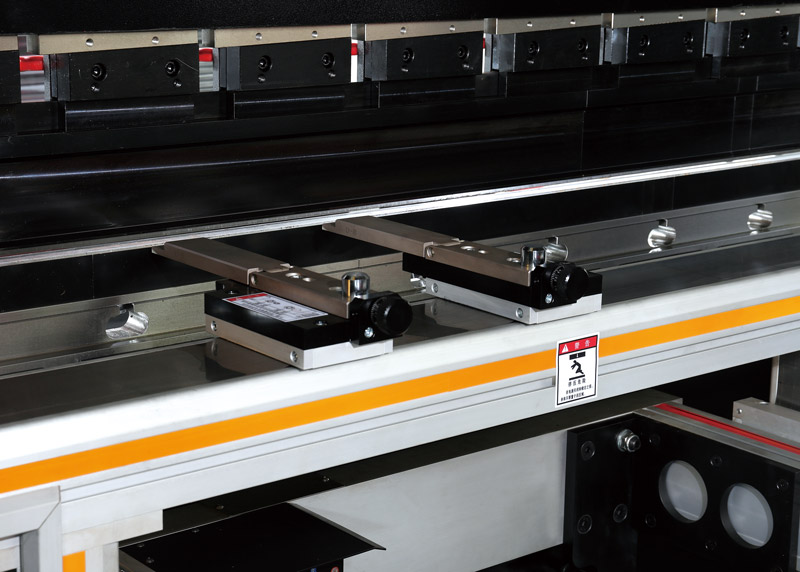

| 6 | Ball screw | Taiwan | HIWIN/PMI |

| 7 | Straight guide rail | Taiwan | Taiwan HIWIN/ PMI |

| 8 | Seal | USA / Japan | USA/Japan NOK |

| 9 | Air switch | France | Schneider |

| 10 | Miniature relay | France | Schneider |

| 11 | Ac contactor | France | Schneider |

| 12 | Button | France | Schneider |

| 13 | Electrical components | France | Schneider |

| 14 | Socket joint | German | German original |

111

Copyright © 2025 Foshan Ragos NC Equipment co.,LTD. (panel bender) | All Rights Reserved

We are here to help you! If you close the chatbox, you will automatically receive a response from us via e-mail. Please be sure to leave your contact details so that we can better assist you.