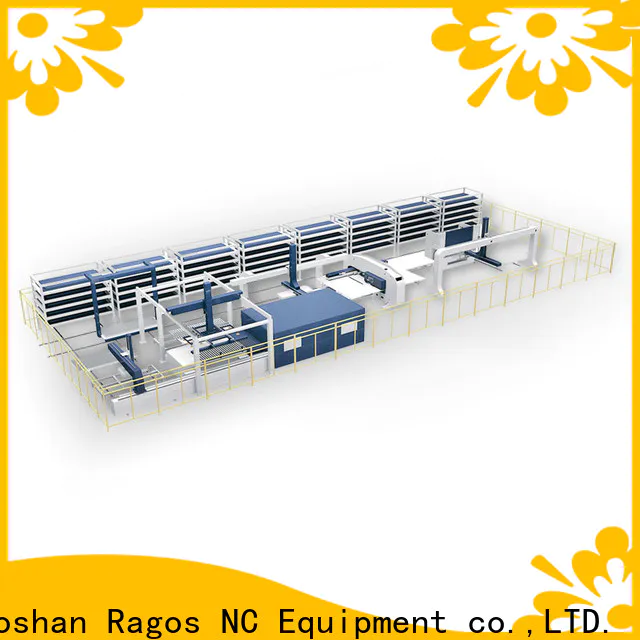

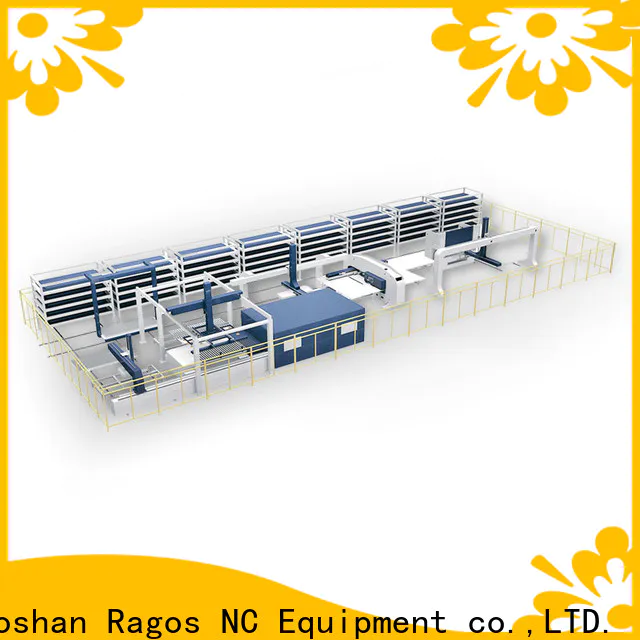

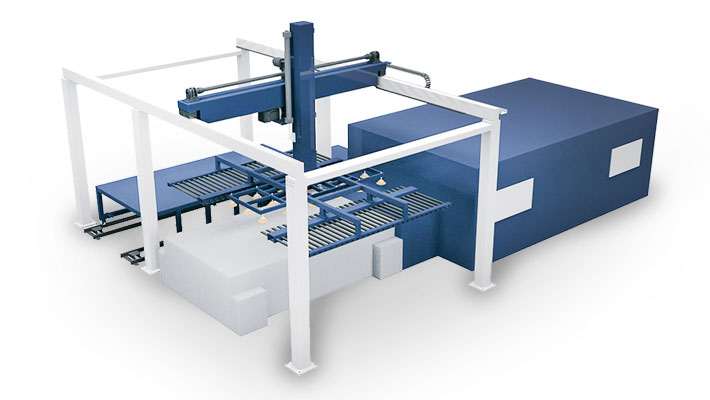

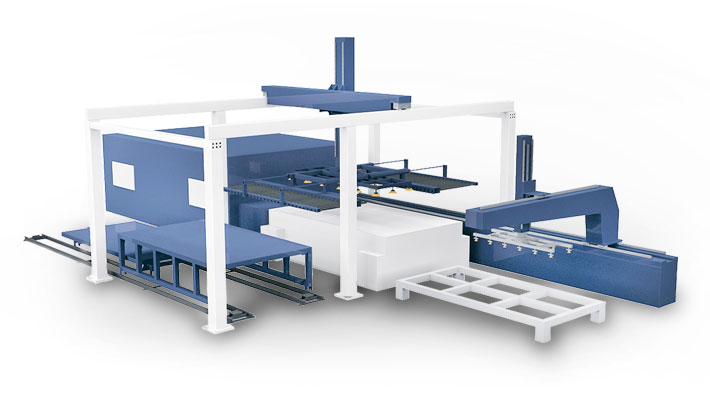

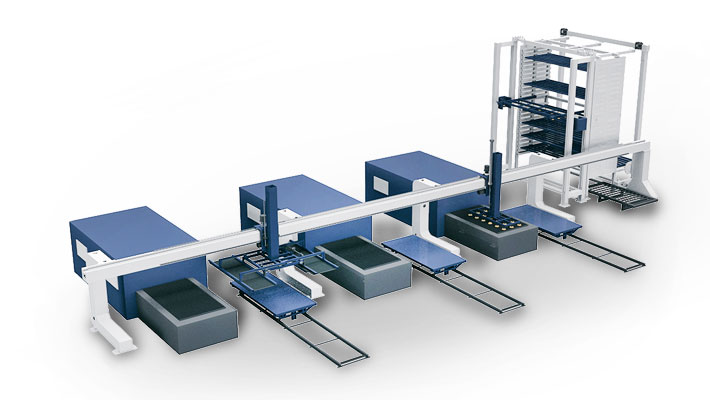

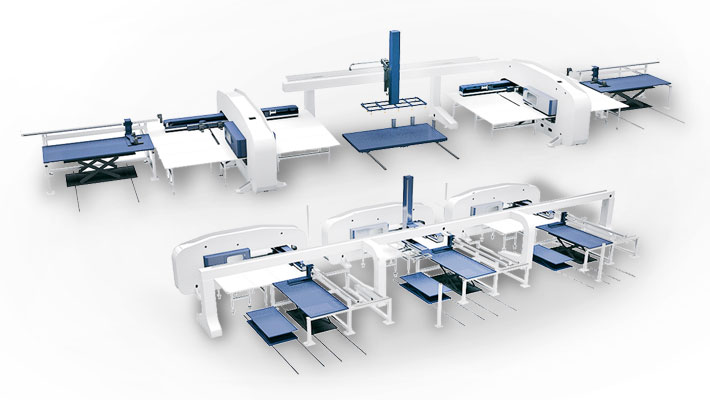

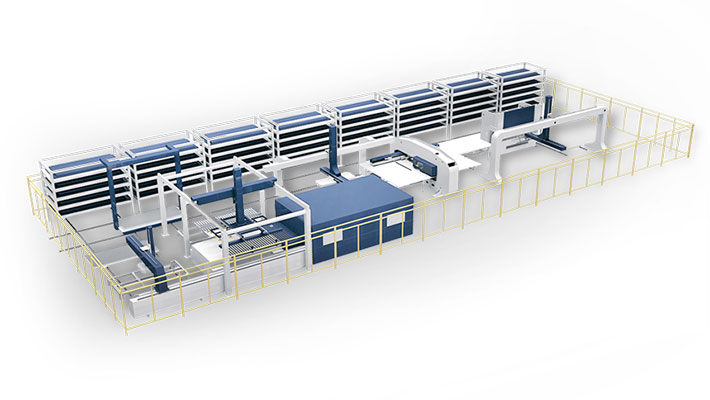

1. Automated work cycle, with the help of fast loading and unloading function, so that the machine tool has a higher utilization rate.

2. Matching the warehousing units of the whole upper and lower orders, the production rhythm is more optimized.

Copyright © 2025 Foshan Ragos NC Equipment co.,LTD. (panel bender) | All Rights Reserved

We are here to help you! If you close the chatbox, you will automatically receive a response from us via e-mail. Please be sure to leave your contact details so that we can better assist you.