HG Series has the most advantage in thick or long plate. It brings best quality, simple operation and an attractive price-performance ratio. This means you can save the cost to make more profit within precise results as well as the highest safety standards.

| Parts name | Parameter | Unit | |

| Nominal pressure | 1600 | KN | |

| Workbench length | 4000 | mm | |

| Distance between columns | 3500 | mm | |

| Slider stroke | 250 | mm | |

| Open height | 500 | mm | |

| Throat depth | 400 | mm | |

| Axis number of NC | Y1、Y2、X、R、V | axes | |

| Main motor power | 15 | kw | |

| Speed of slide | Fast down | 160 | mm/s |

| Work | 10 | mm/s | |

| Return | 130 | mm/s | |

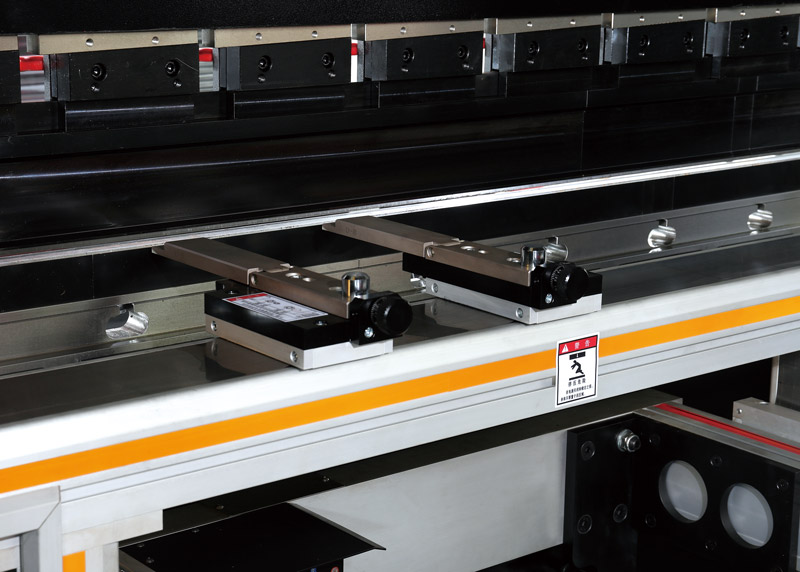

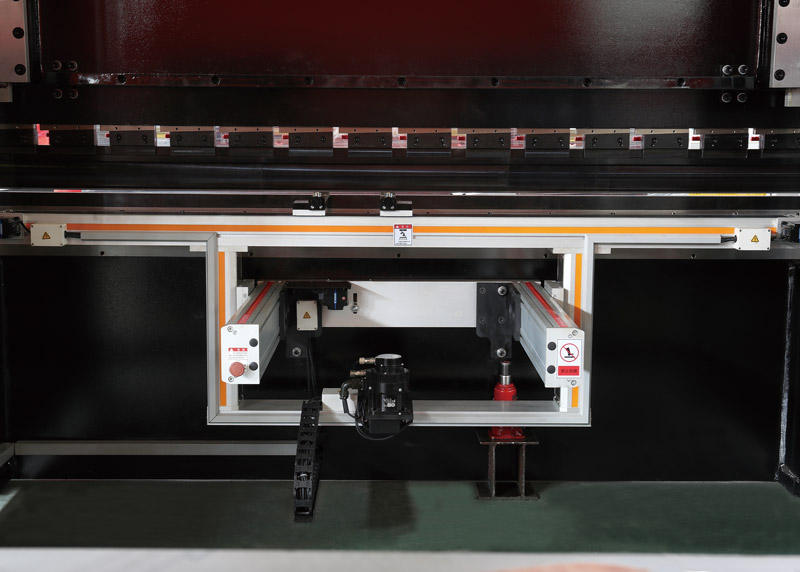

| Back gauge X axis | Stroke | 600 | mm |

| Max. speed | 350 | mm/s | |

| Re-position accuracy | ≤0.05 | mm | |

| Back gauge R axis | Stroke | 200 | mm |

| Max. speed | 200 | mm/s | |

| Re-position accuracy | ≤0.05 | mm | |

| Machine Dimensions | Length | 4600 | mm |

| Width | 1900 | mm | |

| Height | 2900 | mm | |

| Machine weight | 12000 | Kg | |

| No. | Name | Country | Supplier |

| 1 | NC system | Italy | ESA S630 (optional) |

| Holland | DELEM DA-53 series (optional) | ||

| Switzerland | CYBELEC Cyb Touch12 PS (optional) | ||

| 2 | Servo motor | Japan | Yaskawa |

| 3 | Sealed linear encoder | German | ELGO |

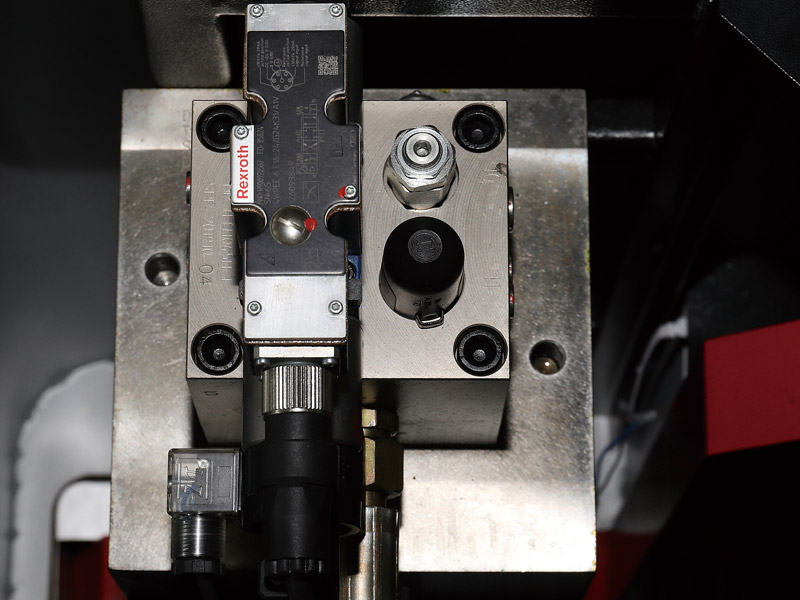

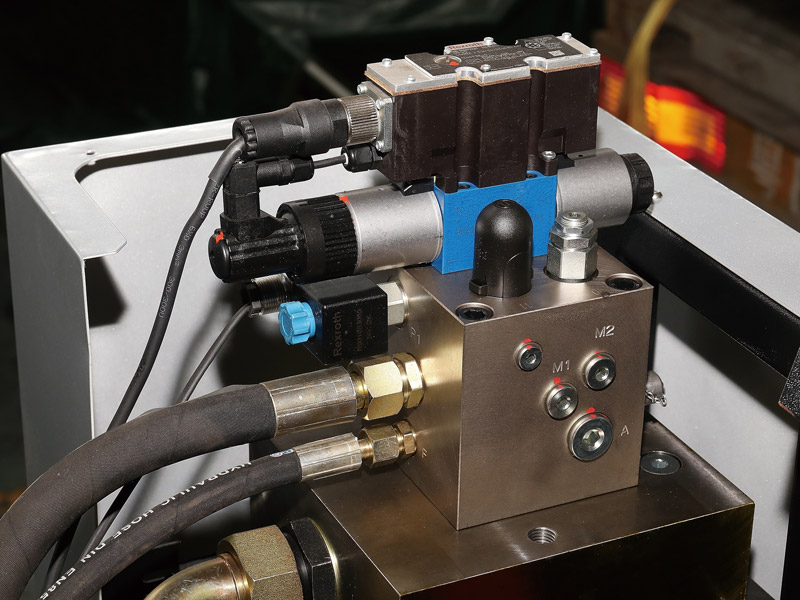

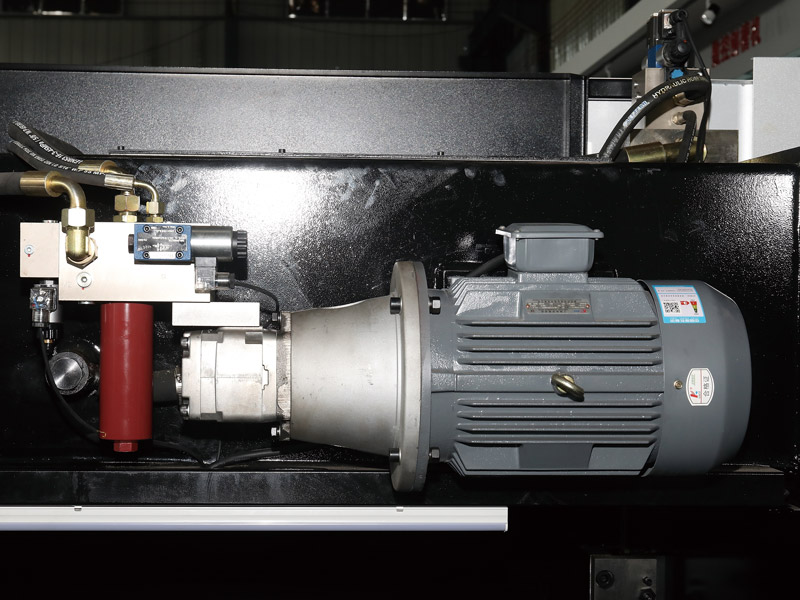

| 4 | Hydraulic system | German | REXROTH/HEROBIGER |

| 5 | Oil pump | German | VIOTH |

| 6 | Ball screw | Taiwan | HIWIN/PMI |

| 7 | Straight guide rail | Taiwan | Taiwan HIWIN/ PMI |

| 8 | Seal | USA / Japan | USA/Japan NOK |

| 9 | Air switch | France | Schneider |

| 10 | Miniature relay | France | Schneider |

| 11 | Ac contactor | France | Schneider |

| 12 | Button | France | Schneider |

| 13 | Electrical components | France | Schneider |

| 14 | Socket joint | German | German original |

111

111

Copyright © 2025 Foshan Ragos NC Equipment co.,LTD. (panel bender) | All Rights Reserved

We are here to help you! If you close the chatbox, you will automatically receive a response from us via e-mail. Please be sure to leave your contact details so that we can better assist you.