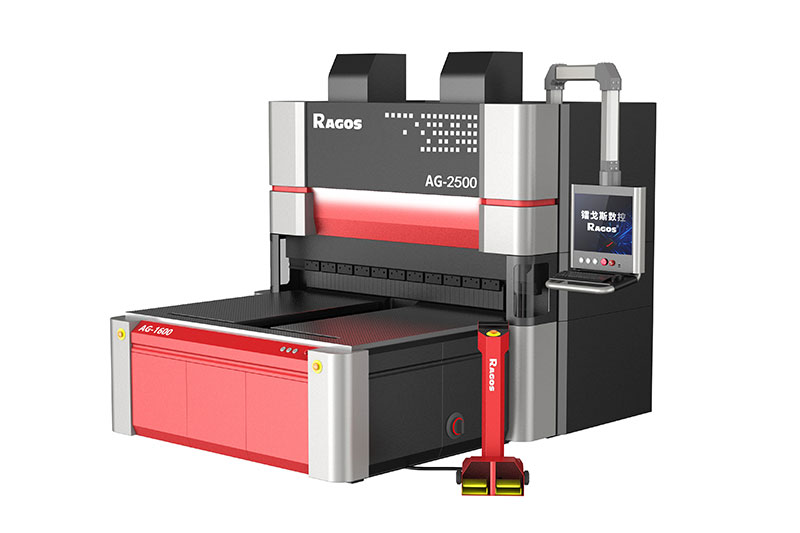

HG Series has the most advantage in thick or long plate. It brings best quality, simple operation and an attractive price-performance ratio. This means you can save the cost to make more profit within precise results as well as the highest safety standards.

| Model | Unit | AG-2500 | |

| Bending Length | mm | 2500 | |

| Plate Length | mm | 2500 | |

| Plate Width | mm | 2500 | |

| Bending Height | mm | 175/350 | |

| Min Forming Size (Four sides) | mm | 200*400 | |

| Min Forming Size (Two sides) | mm | 150 | |

| Min Radius | mm | 1.2 | |

| Bending Speed | s | 0.5 | |

| Opening Height | mm | 200/ 400 | |

| Angle | / | 0-360° | |

| Pressure | kN | 500 | |

| Material Thickness | mm | 3 | |

| Numerical System | / | Japan NADIC | |

| Operating System | OS | Win7+OS | |

| Axis | axes | 9/11 | |

| Machine Dimension | Length | mm | 3100 |

| Width | mm | 3750 | |

| Height | mm | 2400 | |

| Machine Weight | kg | 9000 | |

| Part Name | Country | Manufacturer | Remarks |

| Rack | China | Ragos |

|

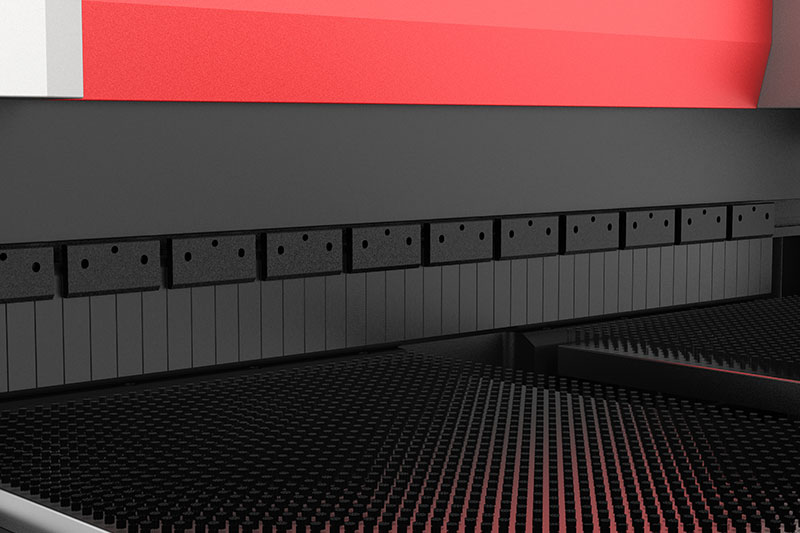

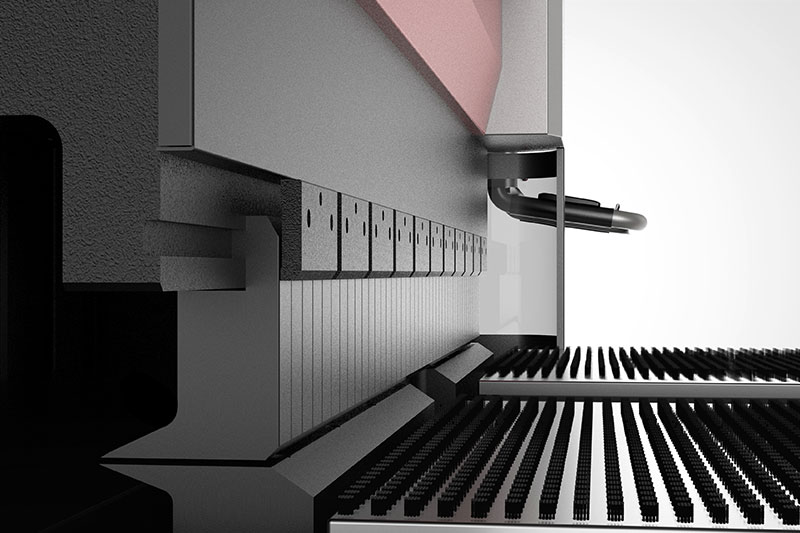

| Mold clamping | China | Ragos | |

| Control system | Japan | Developed with NADIC co., LTD | |

| Servo motor | Japan | SANYO |

|

| Servo | Japan | SANYO | |

| Guide rail | Taiwan | HIWIN |  |

| Ball screw | Taiwan | TBI |  |

| Miniature relay | France | Schneider |

|

| Ac contactor | France | Schneider | |

| Button | France | Schneider | |

| Electrical components | France | Schneider | |

| Reducer | Taiwan | APEX |  |

Copyright © 2025 Foshan Ragos NC Equipment co.,LTD. (panel bender) | All Rights Reserved

We are here to help you! If you close the chatbox, you will automatically receive a response from us via e-mail. Please be sure to leave your contact details so that we can better assist you.