Today is Friday, April 26th, 2019.

The lunar March 22, hai years wu-cheng month decyl the third day.

The islamic calendar August 21, 1440.

Today we talk about the topic is: the numerical control punch parts maintenance requirements focus on?

CNC

press brake machine press pressure, maintenance of the electrical and smooth mechanism.

CNC hydraulic press brake machine pneumatic: air piping: check whether each line situation of leak attack;

Air valve and solenoid valve: the appropriate operation, check the air valve and solenoid valve control is normal;

Balance cylinder: see if air leakage and see if any appropriate smooth;

Whether die cushion: air leak, check whether to have appropriate smooth, check to see if the die cushion fixed screw loose;

Pressure gauge: press the needle is normal.

CNC punch press electrical: electrical control: view controller and operating situation, there is a problem of controller and operating situation, there is a problem of the controller to be replaced.

Tighten loose part, check whether the fuse for the appropriate scale, check whether the insulation of the wire part damage, replace the bad wires;

The motor, check to see if the motor and bracket fixed screw tightening;

Button and foot switch: be careful inspection these switches, if have bad immediately replace;

Relay: see the contact friction losses, loose connection of the disconnection etc. Please carefully smooth implementation of maintenance of CNC press brake machine press, the air clutch smooth components: eliminate all water, see the piece of smooth add oil to the right place;

In smooth smooth system: with reference to the present article introduces the smooth areas to carry out the smooth system protection, to see if the smooth line break, wear, to see if parts have holes, break, damage, check the oil level gauge to inspect the oil level height is in accordance with the specification.

In the case of normal operation, oiled gear and oil change every three months.

Every six months (

About 1500 hours)

Finishing oil tank.

are present in just about every facet of modern life.

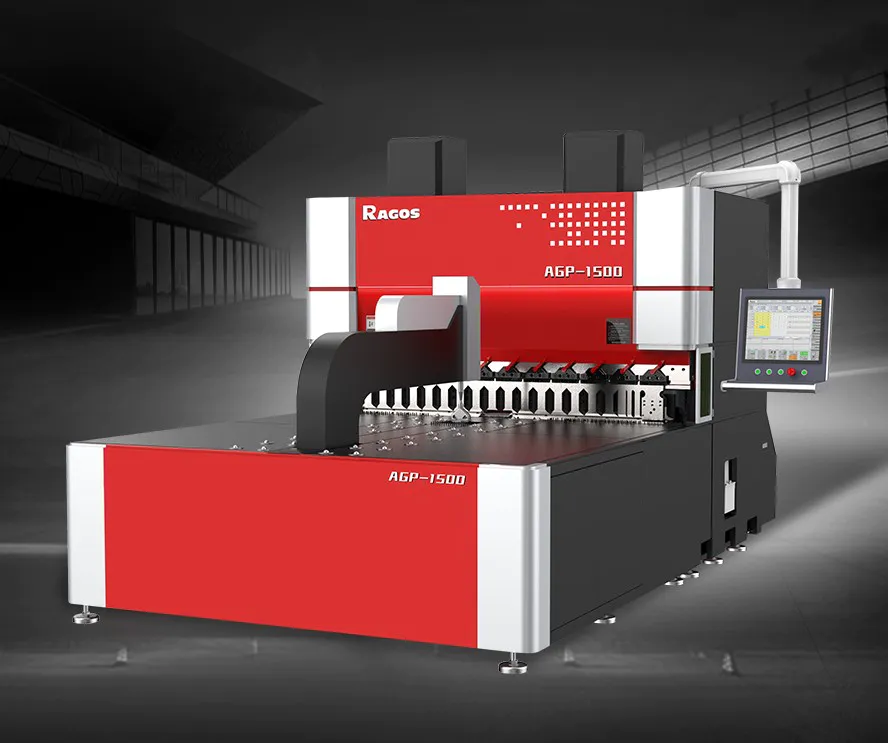

Foshan Ragos NC Equipment co.,LTD. strives to reflect the highest ethical standards in our relationships with members, providers, and shareholders.

Foshan Ragos NC Equipment co.,LTD. incorporates average length of the workweek, average growth in number of small businesses, startup per capita, average of growth of business revenues, five-year business survival rate, industry variety, entrepreneurship index and how digital a state is.

Foshan Ragos NC Equipment co.,LTD. has been making a name for itself as a producer of some of the finest in the China, and it has been singing its praises for some time.

Getting Solution from an idea to production is a complex process. It involves significant research, time, planning and patience. But with the right information, the right resources and the right product, it's possible.