CNC press brake machine daily cleaning and maintenance and the main performance characteristics for CNC planer machine frame layout is messy, the volume is bigger, has brought the usual cleaning must be difficult, so a lot of people ignored the cleaning and maintenance for him.

Insist on hydropower CNC planer machine cleaning, ambitious slot effect can be achieved and to ensure safe operation.

Argues that every six months to the CNC planer machine for a very clean, brush with wool to appearance of dust, with the professional washing liquid to the dirt more local clean, and promptly put in dry ventilated place, avoid rust.

Before started the CNC planer machine engine, to ensure smooth each bearing shell and some other parts to get reasonable smooth, ratio and water temperature rose to 40 ℃ - after launch

Start work again when 50 ℃, and long-term overloaded work is prohibited.

After winter closed CNC planer machine, and the water temperature dropped to 40 ℃ -

50 ℃, cooling water net 牗, write antifreeze.

Ordinary users demand attention to useful maintenance of the engine, make sure CNC press brake machine is an outstanding work.

Pay attention to regular surveys, regular check, found that problem, timely cleaning.

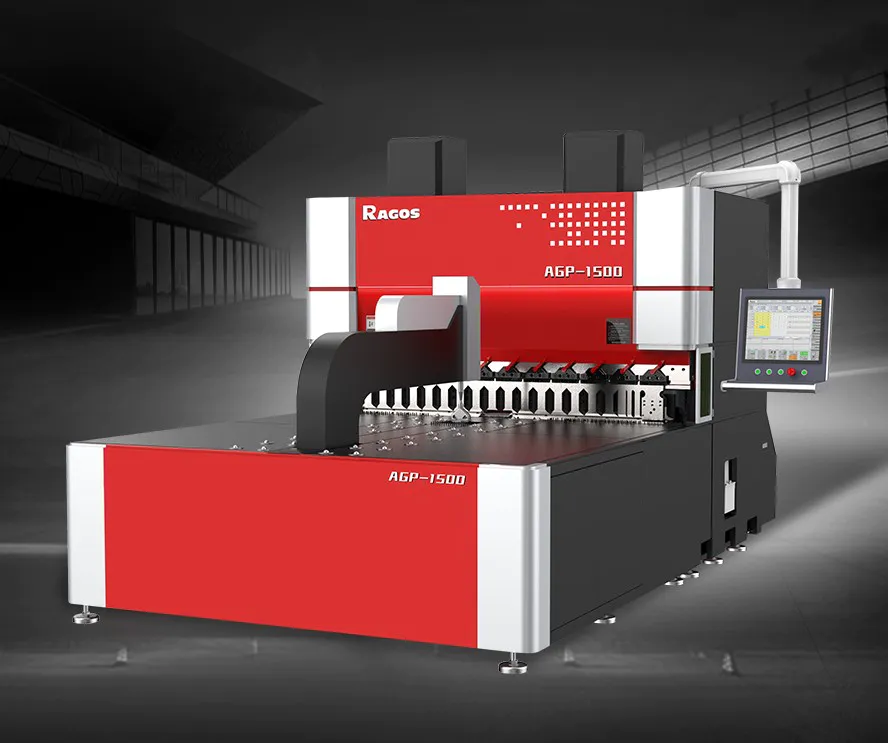

CNC planer machine main performance and features: 1, the machine is made of high strength steel plate welding, the heat preservation tempering heat treatment processing, eliminate the welding stress, high intensity, the fuselage deformation, stability is good.

By the front-end into 2, machining hydraulic clamping, hydraulic clamp pressure, high degree of automation, convenient operation.

3, working independently adjustable, the cutting accuracy can be controlled in 0.

02mm。

4, head adopts servo drive, mobile torque, deceleration is fast, accurate location, high efficiency.

5, main shaft adopt gear and rack driving, strong rigidity, small resistance, increase energy efficiency and save energy.

6, planer slot position servo nc positioning, double wire rod synchronous transmission, accurate location, good parallelism.

After 7, machine tool positioning platform through steel pipe connection, ensure the board face level off, reduce the surface deformation caused by error.

need huge investment, so it is important to shop with caution.

With comprehensive knowledge on Solution,why not visit the highly recommended site Ragos

Press Brake Machine to get a full appreciation of the best ?

Overall, Solution may be a great way for manufacturers to expand their use of technology, but the price could present a significant hurdle for some businesses.