CNC bending machine bending stress adjustment solution 1, bending machine, pressure is calculated according to the tensile strength calculation sheet.

Sheet if your performance is not the same, although the calculated, but the actual force to nature is not the same.

2, if the outside factors, it's just a matter of bending machine, can adjust through the two places, one is the adjustment in the system panel to tensile strength, 2 it is to adjust the system Settings of DA values.

Appear this kind of problem is not necessarily completely is not normal, overload, over a long period of time or an external power supply is not stable, or machine parts of friction increases are likely to lead to this phenomenon, must pay attention to maintenance.

Before bending machine maintenance or brush machine, should turn off the upper die alignment after lower die down, until the work is completed, if you need to boot, or other operations, should will choose in manual mode, and to ensure safety.

Its maintenance content is as follows: 1, the hydraulic circuit check the tank oil level weekly, such as hydraulic system also should check after repair, oil level is lower than the oil window should include hydraulic oil;

This machine is used for the hydraulic oil for ISOHM46 or MOBILDTE25;

New work 2000 hours after the oil should be replaced, later every work of 4000 ~ 6000 hours after the oil should be replaced, the oil change every time, should be cleaning tank;

System oil temperature should be between 35 ℃ ~ 60 ℃, shall not exceed 70 ℃, such as too high will lead to damage of metamorphic oil and accessories.

2 every time, filter oil change, filter should be replaced or cleaned thoroughly;

Associated with the machine alarm or clean oil filter and other abnormal, should be replaced;

Tank on the air filter, clean every three months to check, best 1 year replacement.

3, hydraulic parts monthly cleaning hydraulic parts (

Base board, valve, motor, pump, tubing, etc. )

, prevent dirt from entering the system, cannot use cleaner;

Phone use after a month, check whether there is any deformation on the oil pipe bend, if there is any exception should be replaced, use two months later, should tighten the joint of all parts, for the work should be shut down, when the system pressure.

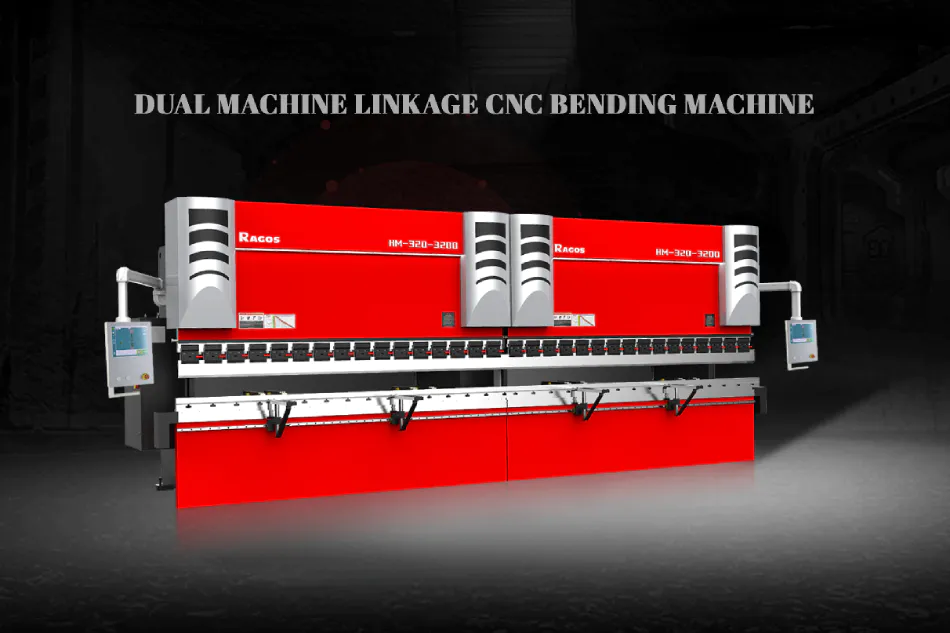

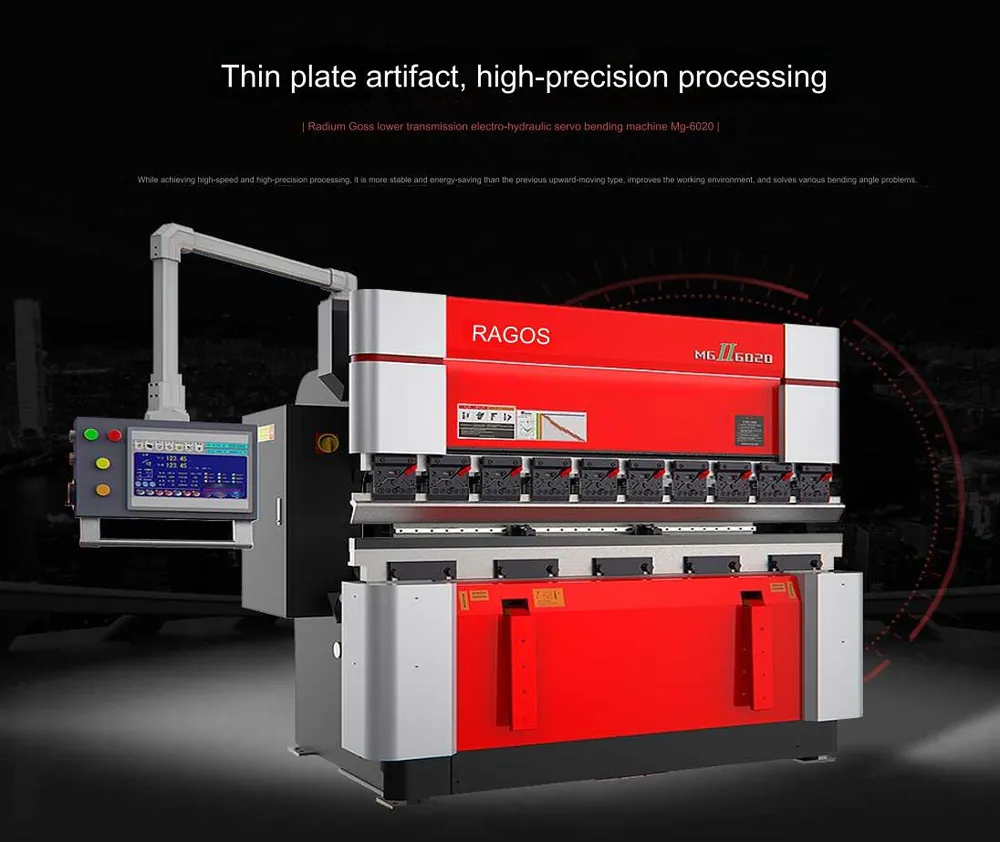

Foshan Ragos NC Equipment co.,LTD. is considered as one of the leading supplier of Solution products in China.

Our vision is to realize the tremendous potential of Solution by providing hydraulic bending machine services that consistently meet our customers’ expectations.

Data has always been important in business, of course. But with the arrival of digital data—its volume, depth, and accessibility—it has become clear it is key to helping Foshan Ragos NC Equipment co.,LTD. develop sustainable competitive advantage.

Solution has obtained many affirmation in the market. Undoubtedlly, our customers are totally satisfied with our products.