CNC bending machine mould is now widely used, so the demand is very big, from the perspective of the manufacturing process of the mould, the molding mold, hot, cold work mould, plastic mould etc. These links are used in the CNC bending machine mold.

Aerospace is the most traditional and most important of CNC bending machine mold use category.

On the other hand, from the point of its development process, the end of the 19th century to the middle of the 20th century, CNC bending machine mold material is given priority to with high speed steel;

In the 70 s, people use of high pressure technology of polycrystalline diamond, diamond so that the use of CNC bending machine tooling size expanded to aviation, spaceflight, cars, electronics, stone and other multiple categories, both bending machine so inductive, CNC bending machine mould length about every career is often important.

In the profession, CNC bending machine mould are commonly used to cutting plane structure.

About CNC bending machine actively using the artifacts, the first to consider important matters is that you want to produce parts, on the basis of end parts can choose a shortest processing mission and workbench, the tonnage of the smallest machine.

For the use of CNC bending machine actively, new machines use a month later, see the tubing twists and turns in presence of deformation, suppose you have abnormal should be replaced.

Carefully consider data of trademark and maximum thickness and length of processing, assuming that most of the thickness of the workpiece is 16 ga (

Ga.

Is the abbreviation of the GAUGE, is a kind of originated in North America about the length of the diameter measurement units, to Browne&

amp;

Sharpe measurement system.

Use after two months, should tighten all accessories of cohesion, the fastening parts, electric hydraulic CNC bending machine should be shutdown condition actively, make the whole system without pressure.

Nothing more than, if engaged in many a bottom die forming, perhaps a 160 tonnage of the machine tool should be considered.

This is attention points, on the use of the new machines every month in the future to clean the hydraulic components, such as substrate, valve, motor, pump, tubing and so on, this is to avoid dirt into the system, can't use the detergent.

These components are generally larger, bag yesterday a lot of aluminum alloy.

Begin to use in medicine and jewelry category, the smaller the number, the greater the diameter, after the promotion is also used to indicate thickness)

And the maximum length of 10 feet (

3.

048 m)

Low carbon steel, then free winding force not more than 50 tons.

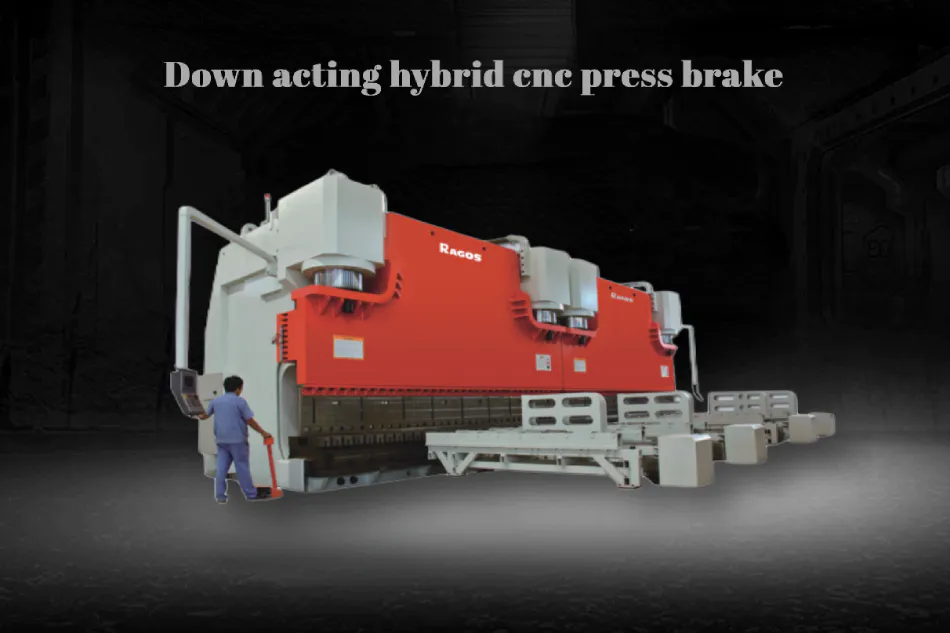

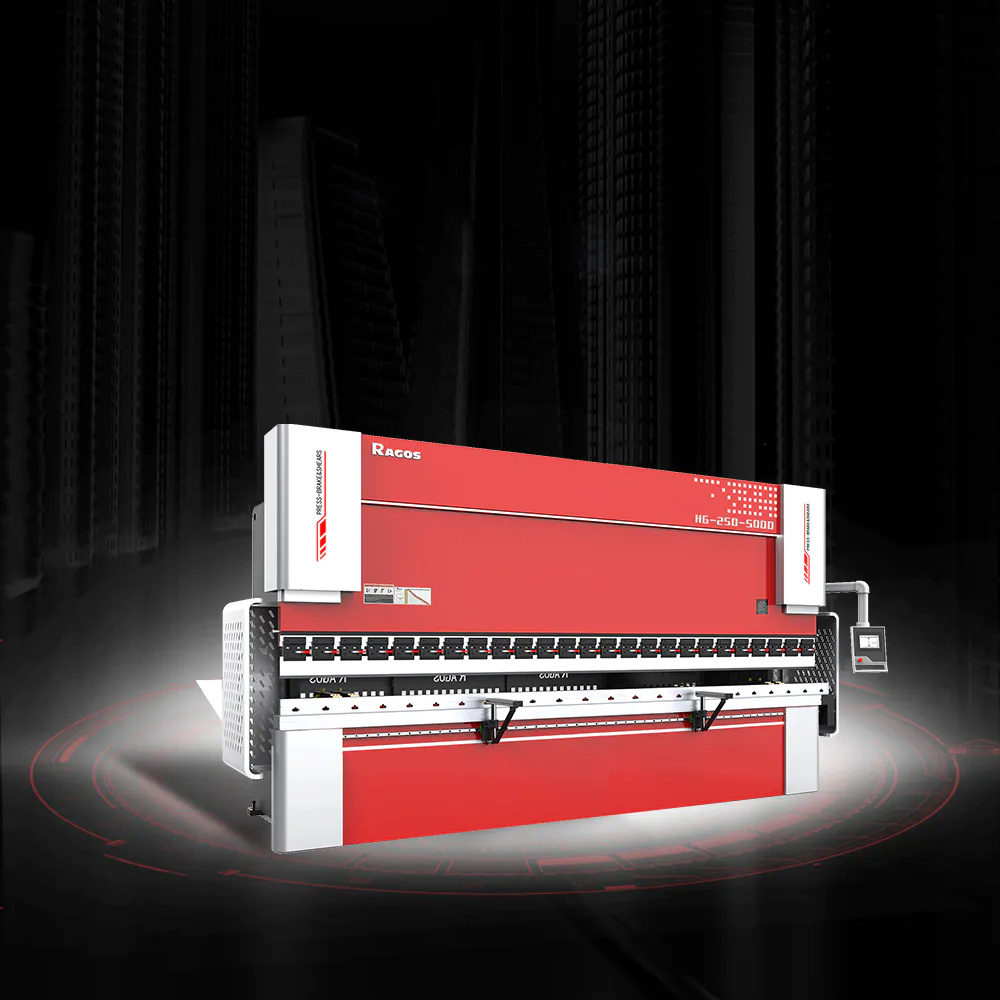

As we have known for quite some time, the success of Ragos in the future will depend greatly on our ability to strike a balance between valuable human insight and interaction with technology.

We believe our ability can raise a giant wave of innovation among the field of Solution.

Ragos is designed to enhance your savings in terms of cost, energy and efforts.If you are interested in our Solution hydraulic shearing machine products, please contact us soon.

Foshan Ragos NC Equipment co.,LTD. will need to find one that fits our needs and budgets, and still turns out a quality product.

We sells Solution and focus on operational procedure and manufacturing facilities small press brake.