Although the manufacturing and accuracy of sheet metal equipment bending machines have been greatly improved than in the past, there is still a big gap between the "Road to Industry 4.0" and "Intelligent Manufacturing and Made in China 2025". "Personalized customization, service-oriented extension, and networked collaboration" also require joint innovation and development in the subdivision of sheet metal equipment manufacturing and the demand side. This innovative development, promotion and application is another increase and liberation of productivity.

The traditional bending of the sheet metal industry needs to solve the following problems: (1) Manufacturing problems: can not achieve multiple varieties, small batches, and fast switching; (2) The problem of low precision of parts: low precision of high-precision workpieces in the sheet metal industry. Unstable quality; (3) The problem of difficult employment for enterprises: the shortage of sheet metal bending operators and the high labor intensity of workers; (4) Comprehensive problems: personnel costs, safety hazards, process layout, management and operation.

The above problems can be solved by selecting a set of intelligent manipulator bending unit: including CNC bending machine, manipulator and guide rail, supporting feeding station, magnetic sheet separation device, centering positioning table, sheet turning mechanism, upper Material gripper, finished product stacking, offline programming software, parametric programming software and secondary development related bending software and extended services.

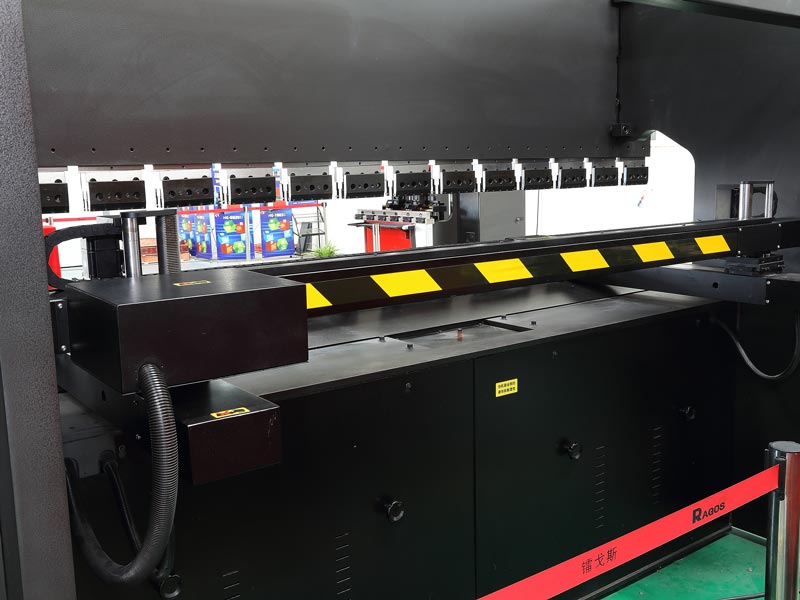

Come to Ragos and choose your bending machine

| Parts name | MG-1003 | Unit | |

| Nominal pressure | 980 | KN | |

| Bending length | 3100 | mm | |

| Distance of side | 2550 | mm | |

| Throat depth | 405 | mm | |

| Machine weight | 6400 | Kg | |

| Opening height | 400 | mm | |

| Slider stroke | 100 | mm | |

| Work speed | Climbing | 52 | mm |

| Bending | 8 | mm | |

| Returning | 46 | mm | |

| Machine dimensions | Length | 3055 | mm |

| Width | 1555 | mm | |

| Height | 2421 | mm | |

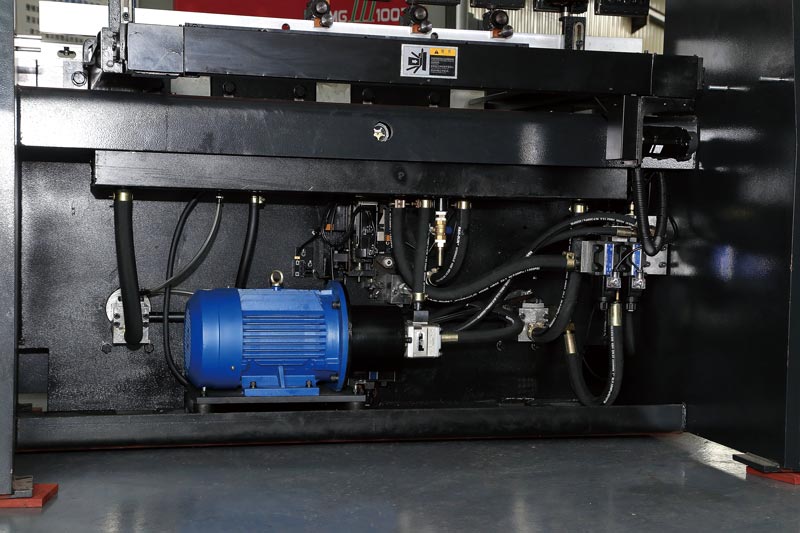

| Main motor power | 7.5 | kw | |

| Cylinders | 3 | pc | |

| Oil tank Capacity | 72 | L | |

| Name | Country | Manufacturer | Remarks |

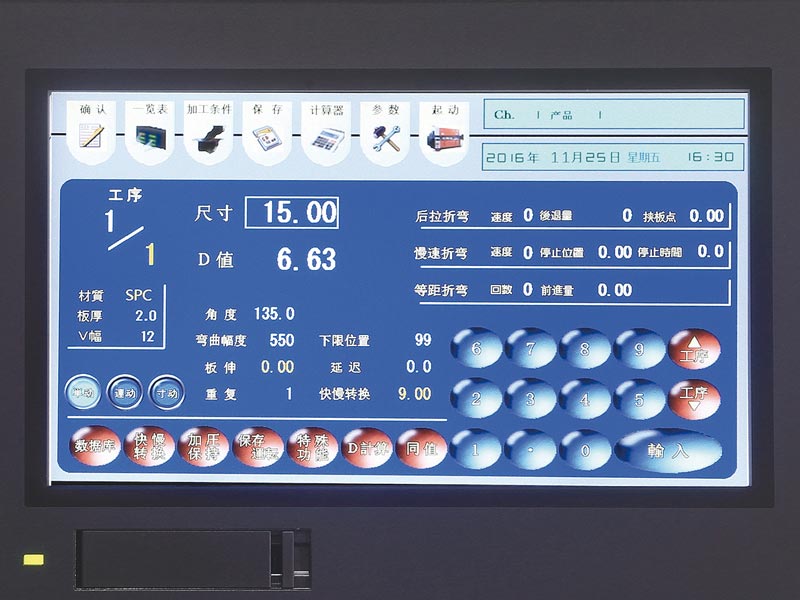

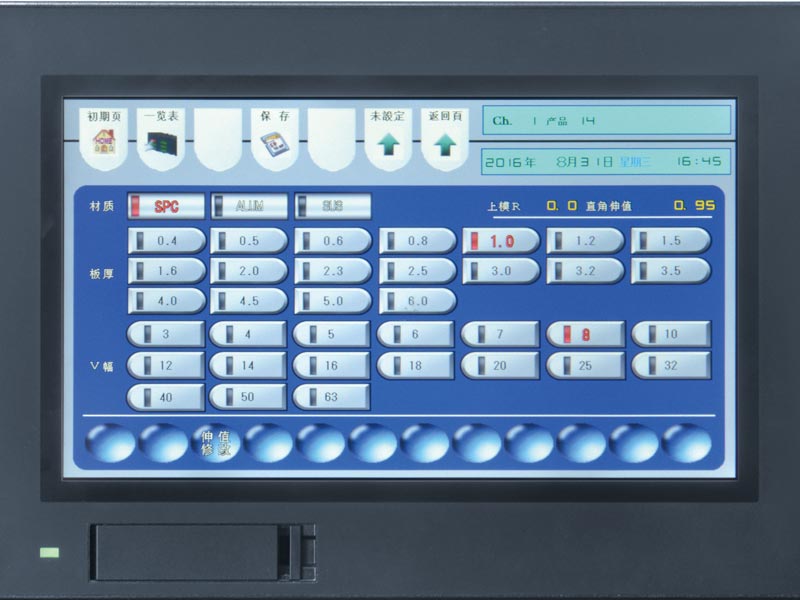

| Control system | Japan | Co-developed with Japan's NADIC |

|

| Servo motor | Japan | Japan Mitsubishi |

|

| Servo | Japan | Japan Mitsubishi |

|

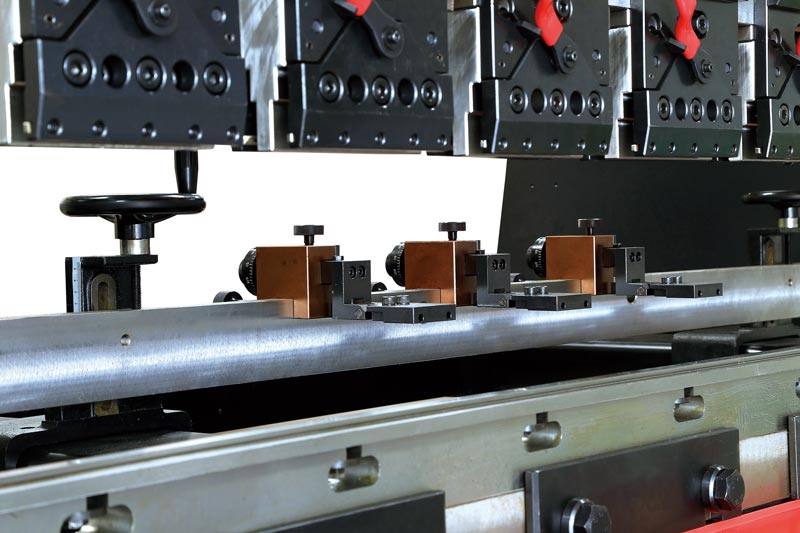

| Mold clamping | Japan | AMADAO original supplier double-sided clip |

|

| Oil pump | Japan / Germany | Japan Nachi/ German Eckerle |

|

| Oil valve | Japan | Japan YUKEN |

|

| Oil seal | Japan | Japan NOK |

|

| Cylinder | Japan | AMADA original supplier |

|

| Guide rail | Taiwan | Taiwan HIWIN |

|

| Ball screw | Taiwan | Taiwan TBI |

|

| PLC control | Japan | Japan Keyence/ Mitsubishi |

|

| Touch screen | China / Japan | Weinview / Japan Keyence |

|

| earing | Japan | Japan NSK |

|

11

Copyright © 2025 Foshan Ragos NC Equipment co.,LTD. (panel bender) | All Rights Reserved

We are here to help you! If you close the chatbox, you will automatically receive a response from us via e-mail. Please be sure to leave your contact details so that we can better assist you.