Today's topic: synthesis of stamping die life affected by various factors, the factors affecting the service life of stamping die is the interval between one of the main factors.

National standard deep throat punch stamping process, between the

press brake machine and are washed to the hole, to have the friction between die and fall materials, and the gap is smaller, the greater the compressive stress of stamping die role, friction is more serious.

So the gap is too small for stamping die life.

And the larger gap can make the punch side and the friction between the material is reduced, and slow clearance due to the limitation of manufacturing and assembly precision, appear the negative impact of the uneven clearance to improve stamping die life.

factory introduced punch mould device of the decrease of the rubber pad can be useful to punch the fuselage reaction, can better ensure the punch press machining accuracy at the same time, also can ensure the service life of the punch die, can say, add punch factory introduction press mold rubber pad works.

Needs pay attention to the processing of metals material, due to demand a large force, plant rubber mat words may lack of formation pressure, therefore, the device is more appropriate punch processing soft rubber mat with thin materials.

Blanking clearance generally adopt the method of cutting paper try to rush and feeler gauge measuring, or see light product with burrs with bending gasket or feeler gauge in general.

When national standard deep throat punch blanking clearance value is bigger, the material by the tensile effect increases, after cutting, due to the elasticity of the material, salt pieces size shrinkage in the direction of the entity, make fall with size less than die size, while punching parts of aperture is greater than the size of punch;

When the clearance is small, elasticity of the material make fall materials size increases, and punching a aperture is smaller.

Clearance fit, can make the upper and lower crack and the direction of maximum shear stress superposition, the planer puncher of blunt cutting surface is flat, smooth, burr, smaller parts of the cross section quality is better.

Gap is too small or too big to upper and lower crack don't overlap.

Clearance after hours, the middle part of upper and lower crack was the second cut, torn surface produces on the cross section, ping to form the second euphotic zone, in the end a long burr.

In a blunt cutting surface quality.

National standard deep throat press the guide rail due to wear and tear on both sides of the slider, lead to slider sway, and mould guide pin.

Clearance is too large, it hit gap is too small, and makes a cacophony of noise.

Saw this article today, I do not know to what state to normal friends should know how to adjust now.

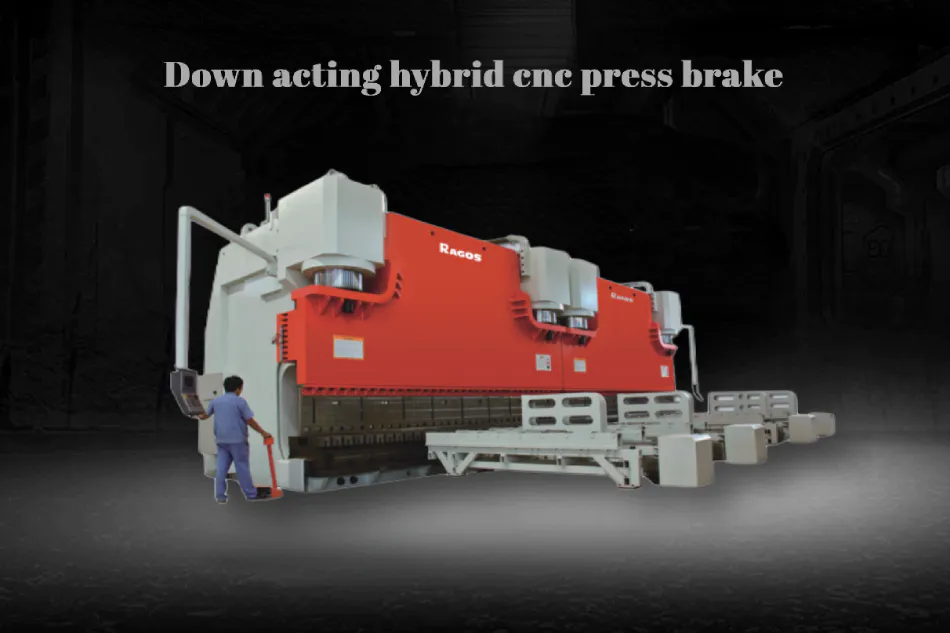

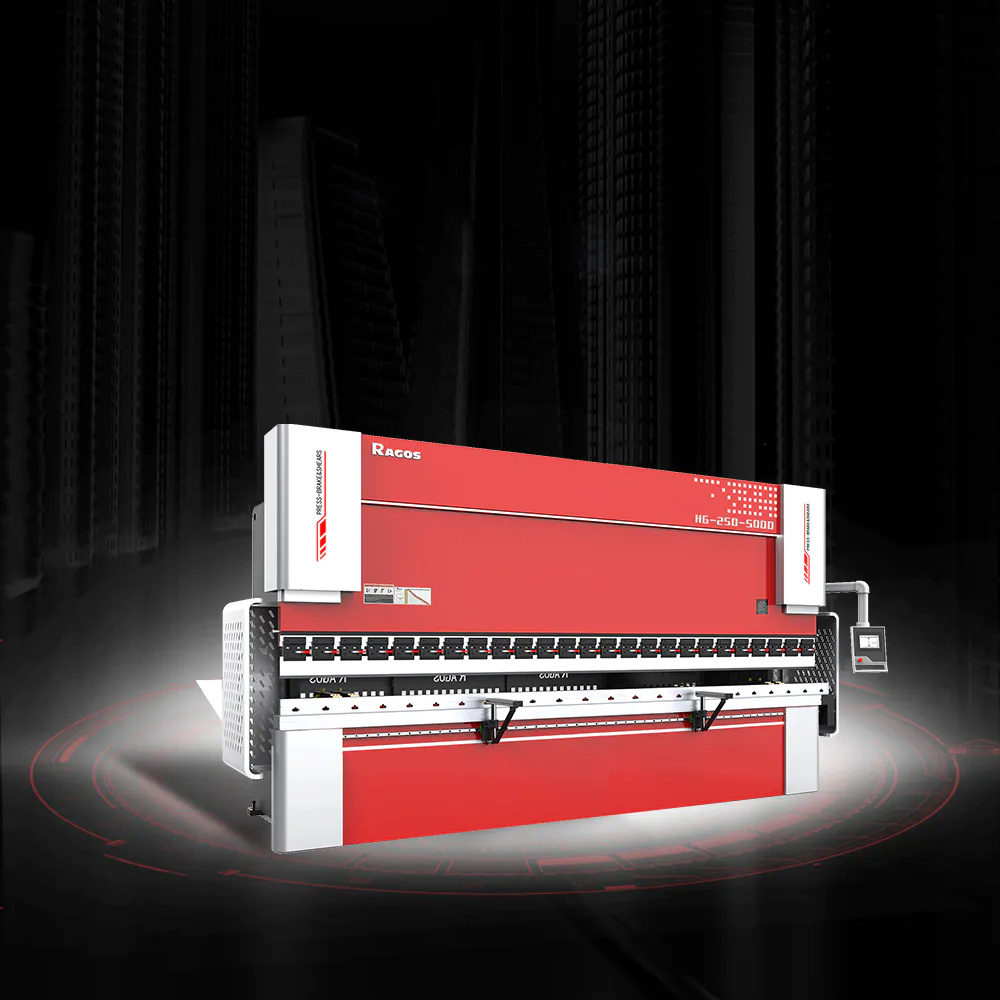

Many of us have heard about Solution and seen some of these units in operation in hydraulic shearing machine, sheet metal equipment and hydraulic bending machine spaces.

If you are ready to stop the problem of metal shearing machine and go back to normal, contact us at Ragos

Press Brake Machine. Foshan Ragos NC Equipment co.,LTD. is ready to help you out.

Visit Ragos Press Brake Machine to find recent dynamics of Solution and contact Foshan Ragos NC Equipment co.,LTD. for the latest and most capable in global market.