small make up today using 1500 - share with you about the

press brake machine

2000 hours in this stage, what needs to be done to press maintenance.

First of all, the press brake machine press lubrication oil gushes oil amount and pressure detector function test and adjustment.

Air system of the filter, oil feeder adjustment valve function of impurities and moisture test view with the necessary adjustments.

Air pressure switch setting to view and pressure detector function test and adjustment.

Die height indicator switch value view with the check and adjustment of measured values.

Die height adjustment device of the sprocket, chain, transmission shaft, worm gear and worm other components such as presence of loose, abnormal and chain tension check and adjustment.

Gear box cover apart and internal parts wear loose and rows of view and tank cleaning, smooth oil change new and operating conditions, noise, vibration test to check.

Each part of the transmission system of injection point of the oil amount and pressure test and adjustment.

From the brake of the piston movement, the brake point of view, and to make the piece from the brake gap abrasion value test tally with the necessary adjustments.

Second, press slide quick guide rail and guide gap measurement and friction surface view, adjusted calibration when necessary.

Flywheel bearing increase manual grease and smooth line, the top view.

Balance oil cylinder and oil smooth system, pick up top test view.

Motor circuit and electric circuit of the insulation resistance test operation view.

The machine precision (

Perpendicularity, parallelism, inductive gap, etc. )

Test, if necessary, adjust the proofreading.

Finally do press brake machine and accessories of the clean appearance, check and mechanical foot (

Basis)

Solid screw, nut locking and horizontal view adjustment if necessary.

Smooth to the oil system of pu, pipeline valve, such as cleaning and maintenance and check.

Air system of pneumatic components, pipeline cleaning and maintenance, such as check and action test.

今天,我想与你分享冲床维修应该做什么后用于1500到2000小时。

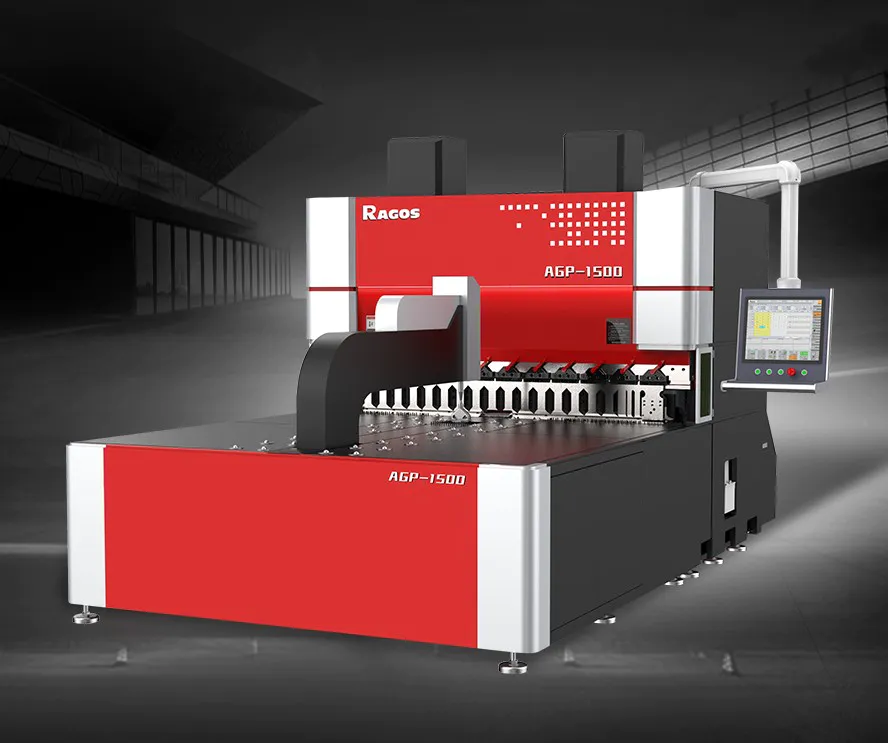

Everyone who has a hydraulic shearing machine wants it to look metal shearing machine. However, in order to achieve that, it normally involves investing in a hydraulic bending machine Solution. Foshan Ragos NC Equipment co.,LTD. can offer you the best solution.

Compare the various types of that are available. At Ragos

Press Brake Machine, the range is constantly being updated with new models, technical details and competitive prices.

Solution receives the updates through industry associations, internal legal counsel, regional associations and legal publications.

Solution are less complex compared with sheet metal press machine.

Deeper connections between Foshan Ragos NC Equipment co.,LTD. and customers can be made when we're thinking out of the box and meeting outside of manufacturing work.